Subaru Crosstrek Service Manual: Inspection

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Fuel Pump Relay

INSPECTION

1. Check that the fuel pump relay has no deformation, cracks or other damages.

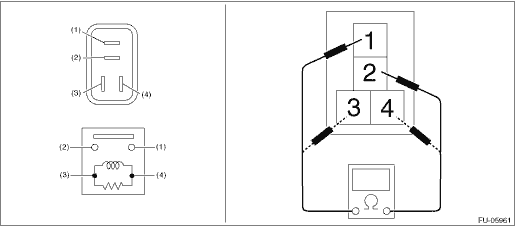

2. Measure the resistance between fuel pump relay terminals.

Terminal No. | Standard |

1 and 2 | 1 M? or more |

3 and 4 | 93.8 — 136.4 ? (when 20°C (68°F)) |

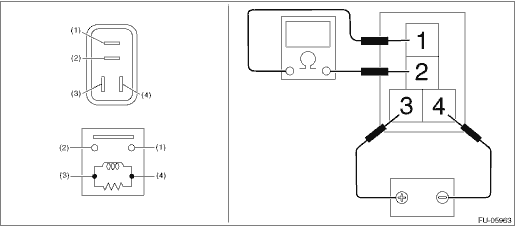

3. Connect battery positive terminal to terminal No. 3 and battery ground terminal to terminal No. 4, and measure the resistance between the fuel pump relay terminals.

Terminal No. | Standard |

1 and 2 | Less than 1 ? |

Fuel pump relay

Fuel pump relay

...

Removal

Removal

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Fuel Pump RelayREMOVAL1. Disconnect the ground cable from battery.2. Remove the glove box. Glove Box > REMOVAL">3. Remove the fuel pump relay from ...

Other materials:

Dtc p0198 engine oil temperature sensor "a" circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0198 ENGINE OIL TEMPERATURE SENSOR "A" CIRCUIT HIGHDTC detecting condition:Immediately at fault recognitionTrouble symptom:• Hard to start• Improper idling• Poor driving performanc ...

Electrical component location Location

ENGINE (DIAGNOSTICS)(H4DO) > Electrical Component LocationLOCATION1. CONTROL MODULE(1)Engine control module (ECM)(3)Malfunction indicator light(4)Data link connector(2)Delivery (test) mode fuse 2. SENSOR(1)Mass air flow and intake air temperature sensor(5)Crankshaft position sensor(9)Intake ca ...

Adjustment

SECURITY AND LOCKS > Impact SensorADJUSTMENT1. CHECK IMPACT SENSOR1. Pull out the key from the ignition switch, or turn the ignition switch to OFF.2. Close all the windows.3. Close all the doors and rear gate. Leave open the front hood.4. Press the LOCK button of the keyless transmitter or access ...