Subaru Crosstrek Service Manual: Inspection

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Camshaft Position Sensor

INSPECTION

1. CAMSHAFT POSITION SENSOR (METHOD WITH OSCILLOSCOPE)

1. Prepare an oscilloscope.

2. Remove the glove box. Glove Box > REMOVAL">

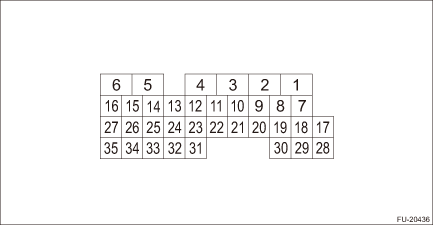

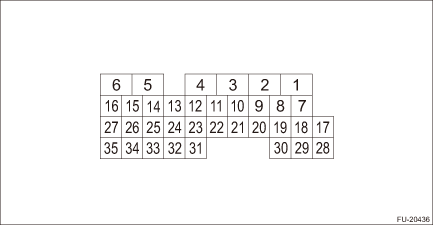

3. Connect the probe to ECM connector.

• Intake camshaft position sensor

• Exhaust camshaft position sensor

Camshaft position sensor | Terminal No. | Probe | |

Intake | RH | 26 | + |

LH | 15 | + | |

Exhaust | RH | 14 | + |

LH | 25 | + | |

RH and LH | 3 | − | |

4. Start the engine and let it idle.

5. Check the waveforms and voltage.

NOTE:

For waveform and voltage, refer to “Engine Control Module (ECM) I/O Signal”. Engine Control Module (ECM) I/O Signal > ELECTRICAL SPECIFICATION">

6. After inspection, install the related parts in the reverse order of removal.

2. OTHER INSPECTIONS

Check that the camshaft position sensor has no deformation, cracks or other damages.

Removal

Removal

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Camshaft Position SensorREMOVAL1. INTAKE SIDE1. Disconnect the ground cable from battery.2. Remove the air intake duct. (RH side only) Air Intake Duct > RE ...

Other materials:

Dtc p1498 coil 4 egr "a" control circuit low

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P1498 COIL 4 EGR "A" CONTROL CIRCUIT LOWDTC DETECTING CONDITION:Immediately at fault recognitionTROUBLE SYMPTOM:• Improper idling• Poor driving performance• Engine breathingCAUTION: ...

Double trip meter

Type A

Trip knob

Type B

Trip knob (U.S.-spec. models)

Trip knob (except U.S.-spec. models)

This meter displays the two trip meters

when the ignition switch is in the "ON"

position.

The trip meter shows the distance that the

vehicle has been driven since you last set

it to ...

Removal

IGNITION(H4DO) > Spark PlugREMOVALSpark plug:Refer to “SPECIFICATION” for spark plug. General Description > SPECIFICATION">1. RH SIDE1. Disconnect the ground cable from battery. NOTE">2. Remove the air cleaner case. Air Cleaner Case > REMOVAL">3. Disco ...