Subaru Crosstrek Service Manual: Electrical specification

CONTROL SYSTEMS > AT Shift Lock Control System

ELECTRICAL SPECIFICATION

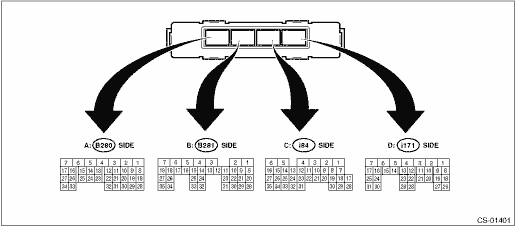

• Model without push button ignition switch

Item | Connector No. | Terminal No. | Input/Output signal |

Measured value and measuring conditions | |||

Battery power supply | B281 | 6 | 9 — 16 V |

7 | |||

i84 | 6 | ||

Ignition power supply | B280 | 32 | 10 — 15 V when ignition switch is at ACC. |

B281 | 3 | 10 — 15 V when ignition switch is at ON or START. | |

TCM (“P” range) | B281 | 20 | Can not be measured because of digital communication |

28 | |||

Stop light and brake switch | B280 | 10 | 9 — 16 V when the stop light & brake switch is ON. 0 V when the stop light & brake switch is OFF. |

“P” range switch | B281 | 18 | Less than 1.5 V when select lever is in “P” range 8 V or more when select lever is in positions other than “P” range. |

Solenoid unit signal | B281 | 5 | 8.5 — 16 V when shift lock is released. 0 V when shift lock is operating. |

Key warning switch signal | B280 | 4 | 9 — 16 V when key is inserted. 0 V when key is removed. |

Key lock solenoid signal | B281 | 4 | 7.5 — 16 V when the key is inserted with the select lever shifted in positions other than “P” range. 0 V at other conditions than above. |

Ground | B280 | 1 | — |

i84 | 1 | ||

Delivery (test) mode signal | i84 | 27 | Can not be measured because of digital communication |

35 |

• Model with push button ignition switch

Item | Connector No. | Terminal No. | Input/Output signal |

Measured value and measuring conditions | |||

Battery power supply | B281 | 6 | 9 — 16 V |

7 | |||

i84 | 6 | ||

Ignition power supply | B280 | 32 | 10 — 15 V when ignition switch is at ACC. |

B281 | 3 | 10 — 15 V when ignition switch is at ON or START. | |

TCM (“P” range) | B281 | 20 | Can not be measured because of digital communication |

28 | |||

Stop light and brake switch | B280 | 10 | 9 — 16 V when the stop light & brake switch is ON. 0 V when the stop light & brake switch is OFF. |

“P” range switch | B281 | 18 | Less than 1.5 V when select lever is in “P” range 8 V or more when select lever is in positions other than “P” range. |

Solenoid unit signal | B281 | 5 | 8.5 — 16 V when shift lock is released. 0 V when shift lock is operating. |

Ground | B280 | 1 | — |

i84 | 1 | ||

Delivery (test) mode signal | i84 | 27 | Can not be measured because of digital communication |

35 |

Inspection

Inspection

CONTROL SYSTEMS > AT Shift Lock Control SystemINSPECTION1. SHIFT LOCK OPERATION• Model without push button ignition switchSTEPCHECKYESNO1.CHECK COMMUNICATION OF SUBARU SELECT MONITOR.1) Turn ...

Other materials:

Fuses

CAUTION

Never replace a fuse with one having

a higher rating or with material

other than a fuse because serious

damage or a fire could result.

The fuses are designed to melt during an

overload to prevent damage to the wiring

harness and electrical equipment. The

fuses are located in two fuse ...

Operation

EyeSight (DIAGNOSTICS) > EyeSight Temporary Code(s) DisplayOPERATIONIf the EyeSight pause code is detected from the stereo camera, all the functions of the EyeSight excluding the conventional cruise control stop temporarily and cannot be used. When the failure is resolved, the function starts ope ...

List of diagnostic trouble code (dtc) List

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > List of Diagnostic Trouble Code (DTC)LIST• Models without EyeSightDTCItemContent of diagnosisReferenceC1211FRONT RIGHT ABS SENSOR CIRCUITOpen/high input of front ABS wheel speed sensor RH Diagnostic Procedure with Diagnostic Trouble Code (DTC) ...