Subaru Crosstrek Service Manual: Dtc p2270 o2 sensor signal biased/stuck lean bank 1 sensor 2

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P2270 O2 SENSOR SIGNAL BIASED/STUCK LEAN BANK 1 SENSOR 2

DTC detecting condition:

Detected when two consecutive driving cycles with fault occur.

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

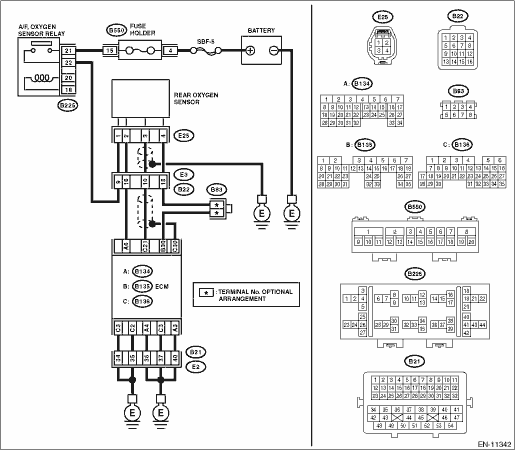

Wiring diagram:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK REAR OXYGEN SENSOR CONNECTOR.

Has water entered the connector?

Completely remove any water inside.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P2270 O2 SENSOR SIGNAL BIASED/STUCK LEAN BANK 1 SENSOR 2">Go to Step 2.

2.CHECK HARNESS BETWEEN ECM AND REAR OXYGEN SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connector from rear oxygen sensor.

4) Measure the resistance of harness between ECM connector and rear oxygen sensor connector.

Connector & terminal

(E135) No. 30 — (E25) No. 4:

(E136) No. 21 — (E25) No. 3:

Is the resistance less than 1 ??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P2270 O2 SENSOR SIGNAL BIASED/STUCK LEAN BANK 1 SENSOR 2">Go to Step 3.

Repair the open circuit of harness between ECM connector and rear oxygen sensor connector.

3.CHECK HARNESS BETWEEN ECM AND REAR OXYGEN SENSOR CONNECTOR.

1) Connect the connector to ECM.

2) Turn the ignition switch to ON.

3) Measure the voltage between rear oxygen sensor connector and engine ground.

Connector & terminal

(E25) No. 3 (+) — Engine ground (−):

Is the voltage 0.15 V or more?

Repair the short circuit to power in the harness between ECM connector and rear oxygen sensor connector.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P2270 O2 SENSOR SIGNAL BIASED/STUCK LEAN BANK 1 SENSOR 2">Go to Step 4.

4.CHECK EXHAUST SYSTEM.

Check exhaust system parts.

NOTE:

Check the following items.

• Looseness and improper fitting of exhaust system parts

• Damage (crack, hole etc.) of parts

• Damage (crack, hole etc.) between front oxygen (A/F) sensor and rear oxygen sensor

Is there any fault in exhaust system?

Repair or replace faulty parts.

Replace the rear oxygen sensor. Rear Oxygen Sensor">

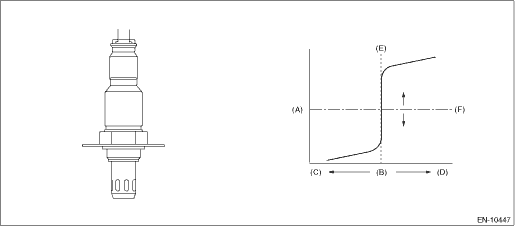

1. OUTLINE OF DIAGNOSIS

Detect the stuck of rear oxygen sensor voltage in lean state.

When rear oxygen sensor voltage remains below the threshold value for predetermined time, diagnosis interrupts target air fuel ratio for control and raises output voltage.

Judge as NG detecting the stuck in lean state when rear oxygen sensor voltage remains below the threshold value even after the interrupt control.

2. COMPONENT DESCRIPTION

(A) | Electromotive force | (B) | Air fuel ratio | (C) | Lean |

(D) | Rich | (E) | Theoretical air fuel ratio | (F) | Comparative voltage |

3. EXECUTION CONDITION

Secondary parameters | Execution condition |

Battery voltage | ≥ 10.9 V |

Sub feedback | In operation |

Amount of intake air | ≥ 8 g/s (0.28 oz/s) |

Estimated temperature of the rear oxygen sensor element | ≥ 500 °C (932 °F) (CVT model) ≥ 500 °C (932 °F) (MT model) |

Enable conditions at interrupt control are as follows | |

Continuous time when rear oxygen sensor output voltage is less than 0.55 V | ≥ 5 s (CVT model) ≥ 15 s (MT model) |

Air fuel ratio reduced from target air fuel ratio | = Value of Map |

Output voltage of rear oxygen sensor V | 0.000 | 0.150 | 0.200 | 0.400 | 0.600 |

Air fuel ratio reduced from target air fuel ratio % | 15 | 15 | 4 | 4 | 4 |

Output voltage of rear oxygen sensor V | 0.000 | 0.150 | 0.200 | 0.400 | 0.600 |

Air fuel ratio reduced from target air fuel ratio % | 15 | 15 | 4 | 4 | 4 |

4. GENERAL DRIVING CYCLE

Perform the diagnosis only once after the enable conditions have been established.

5. DIAGNOSTIC METHOD

If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Malfunction Criteria | Threshold Value |

Output voltage of rear oxygen sensor | < 0.55 V |

Time needed for diagnosis:

• 15 s (CVT model)

• 25 s (MT model)

Malfunction indicator light illumination: Illuminates when malfunction occurs in 2 continuous driving cycles.

Dtc p2196 a/f /o2 sensor signal biased/stuck rich bank 1 sensor 1

Dtc p2196 a/f /o2 sensor signal biased/stuck rich bank 1 sensor 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2196 A/F /O2 SENSOR SIGNAL BIASED/STUCK RICH BANK 1 SENSOR 1DTC DETECTING CONDITION:Detected when two consec ...

Dtc p2271 o2 sensor signal biased/stuck rich bank 1 sensor 2

Dtc p2271 o2 sensor signal biased/stuck rich bank 1 sensor 2

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2271 O2 SENSOR SIGNAL BIASED/STUCK RICH BANK 1 SENSOR 2DTC detecting condition:Detected when two consecutive ...

Other materials:

Inspection

LUBRICATION(H4DO) > Oil Pressure SystemINSPECTIONSTEPCHECKYESNO1.CHECK ENGINE OIL AMOUNT.Is the engine oil amount normal? Engine Oil > INSPECTION"> Oil Pressure System > INSPECTION">Go to Step 2.Adjust the engine oil amount. Engine Oil > INSPECTION"> After the o ...

Cruise control (if equipped)

NOTE

For models with EyeSight system:

Refer to the Owner's Manual supplement

for the EyeSight system.

Cruise control enables you to maintain a

constant vehicle speed without holding

your foot on the accelerator pedal and it is

operative when the vehicle speed is 25

mph (40 km/h) or more.

WA ...

Inspection

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Inhibitor SwitchINSPECTIONWhen the driving condition or starter motor operation is improper, first check the shift linkage for improper operation. If the shift linkage is functioning properly, check the inhibitor switch.1. Remove the clip (A) from the a ...