Subaru Crosstrek Service Manual: Dtc p2122 throttle/pedal position sensor/switch "d" circuit low

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P2122 THROTTLE/PEDAL POSITION SENSOR/SWITCH "D" CIRCUIT LOW

DTC detecting condition:

Immediately at fault recognition

Trouble symptom:

• Improper idling

• Poor driving performance

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

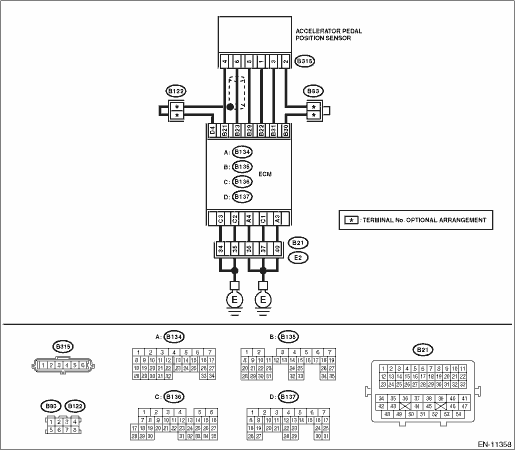

Wiring diagram:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK HARNESS BETWEEN ECM AND ACCELERATOR PEDAL POSITION SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connector from the accelerator pedal position sensor.

4) Measure the resistance between ECM connector and chassis ground.

Connector & terminal

(B135) No. 21 — Chassis ground:

(B135) No. 23 — Chassis ground:

(B135) No. 23 — (B137) No. 4:

Is the resistance 1 M? or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P2122 THROTTLE/PEDAL POSITION SENSOR/SWITCH "D" CIRCUIT LOW">Go to Step 2.

Repair the short circuit to ground in harness between ECM connector and accelerator pedal position sensor connector.

2.CHECK SHORT CIRCUIT INSIDE THE ECM.

1) Connect the connector to ECM.

2) Measure the resistance between accelerator pedal position sensor connector and chassis ground.

Connector & terminal

(B315) No. 6 — Chassis ground:

Is the resistance 1 M? or more?

Replace the accelerator pedal. Accelerator Pedal">

Repair the short circuit to ground in harness between ECM connector and accelerator pedal position sensor connector. Replace the ECM if defective. Engine Control Module (ECM)">

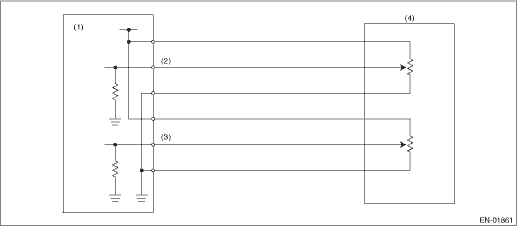

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of accelerator pedal position sensor 1.

Judge as NG if out of specification.

2. COMPONENT DESCRIPTION

(1) | Engine control module (ECM) | (3) | Accelerator pedal position sensor 2 signal | (4) | Accelerator pedal position sensor |

(2) | Accelerator pedal position sensor 1 signal |

3. EXECUTION CONDITION

Secondary Parameters | Execution condition |

Battery voltage | ≥ 6 V |

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Malfunction Criteria | Threshold Value |

Sensor 1 input voltage | < 0.298 V |

Time Needed for Diagnosis: 100 ms

Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs.

Dtc p2119 throttle actuator "a" control throttle body range/performance

Dtc p2119 throttle actuator "a" control throttle body range/performance

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2119 THROTTLE ACTUATOR "A" CONTROL THROTTLE BODY RANGE/PERFORMANCENOTE:For the diagnostic procedur ...

Dtc p2123 throttle/pedal position sensor/switch "d" circuit high

Dtc p2123 throttle/pedal position sensor/switch "d" circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2123 THROTTLE/PEDAL POSITION SENSOR/SWITCH "D" CIRCUIT HIGHDTC detecting condition:Immediately at ...

Other materials:

Installation

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Drive PlateINSTALLATION1. Temporarily install the drive plate and reinforcement drive plate.NOTE:Align the knock pin hole of the crankshaft position sensor plate to the knock pin of the crankshaft to secure the knock pin.2. Set the ST.ST 498497300CRA ...

Installation

EXTERIOR BODY PANELS > Front DoorINSTALLATION1. FRONT DOOR PANEL1. Put a wooden block on a jack and place the panel assembly - front door on it.2. Apply grease to the sliding area of door hinges, and install the door hinge to vehicle.3. Adjust the height by the jack, and temporarily install the p ...

Fuel Procedure

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > FuelPROCEDURE1. RELEASING OF FUEL PRESSUREWARNING:Place “NO OPEN FLAMES” signs near the working area.CAUTION:Be careful not to spill fuel.1. Remove the fuse of fuel pump from main fuse box.2. Start the engine and run it until it stalls.3. After th ...