Subaru Crosstrek Service Manual: Dtc p2119 throttle actuator "a" control throttle body range/performance

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P2119 THROTTLE ACTUATOR "A" CONTROL THROTTLE BODY RANGE/PERFORMANCE

NOTE:

For the diagnostic procedure, refer to DTC P2101. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P2101 THROTTLE ACTUATOR "A" CONTROL MOTOR CIRCUIT RANGE/PERFORMANCE">

1. OUTLINE OF DIAGNOSIS

Judge as NG when the target opening angle and actual opening angle is mismatched or the current to motor is the specified duty or more for specified time continuously.

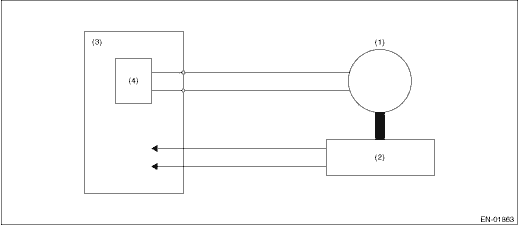

2. COMPONENT DESCRIPTION

(1) | Motor | (3) | Engine control module (ECM) | (4) | Drive circuit |

(2) | Throttle position sensor |

3. EXECUTION CONDITION

Secondary Parameters | Execution condition |

12 V battery system voltage | 6.2 V |

Throttle motor relay command | ON |

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously when the electronic throttle control is operating.

5. DIAGNOSTIC METHOD

Judge as OK and clear the NG when the malfunction criteria below are met.

Diagnosis 1

Malfunction Criteria | Threshold Value |

Output duty to drive circuit | ≥ 95 % |

Time Needed for Diagnosis:

• Engine speed ≥ 500 rpm: 2000 ms

• Engine speed < 500 rpm: 5000 ms

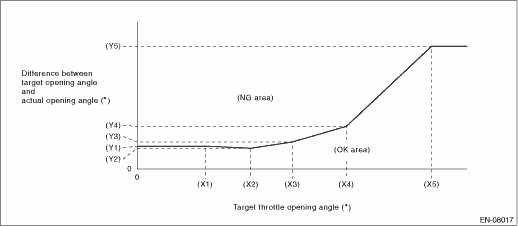

Diagnosis 2

Malfunction Criteria | Threshold Value |

Difference between target opening angle and actual opening angle | Within NG range of Details of Judgment value |

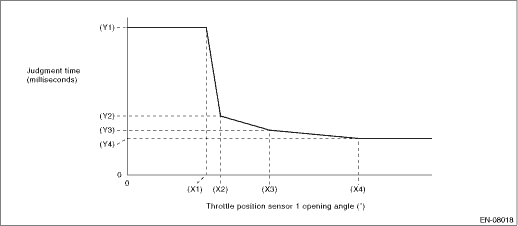

Time Needed for Diagnosis:

• Engine speed ≥ 500 rpm: Refer to Details of Judgment time.

• Engine speed < 500 rpm: 5000 ms

Details of Judgment Value

(X1) | 6.915 ° | (X2) | 11.565 ° | (X3) | 15.785 ° |

(X4) | 21.285 ° | (X5) | 29.965 ° | ||

(Y1) | 4.65 ° | (Y2) | 4.22 ° | (Y3) | 5.5 ° |

(Y4) | 8.68 ° | (Y5) | 25 ° |

Details of Judgment time

(X1) | 8.049999237 ° | (X2) | 9.5 ° | (X3) | 14.5 ° |

(X4) | 23.5 ° | ||||

(Y1) | 1000 ms | (Y2) | 400 ms | (Y3) | 304 ms |

(Y4) | 248 ms |

NOTE:

Judgment time when actual opening angle ≤ target opening angle is always 1000 milliseconds.

Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs.

Dtc p2109 throttle/pedal position sensor "a" minimum stop performance

Dtc p2109 throttle/pedal position sensor "a" minimum stop performance

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2109 THROTTLE/PEDAL POSITION SENSOR "A" MINIMUM STOP PERFORMANCENOTE:For the diagnostic procedure, ...

Dtc p2122 throttle/pedal position sensor/switch "d" circuit low

Dtc p2122 throttle/pedal position sensor/switch "d" circuit low

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2122 THROTTLE/PEDAL POSITION SENSOR/SWITCH "D" CIRCUIT LOWDTC detecting condition:Immediately at f ...

Other materials:

Dtc b2814 power supply low voltage

EyeSight (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B2814 POWER SUPPLY LOW VOLTAGEDetected when the status of 7.0 V or less continues approximately for 5 seconds and is judged to be low-voltage malfunction, or when the +B harness of the stereo camera is broken.DTC ...

Waxing and polishing

Always wash and dry the vehicle before

waxing and polishing.

Use a good quality polish and wax and

apply them according to the manufacturer's

instructions. Wax or polish when

the painted surface is cool.

Be sure to polish and wax the chrome trim,

as well as the painted surfaces. Loss of

...

List

BODY CONTROL SYSTEM (DIAGNOSTICS) > Read Current DataLISTItems to be displayedUnit of measureContentNoteBATT voltage (control)10 — 15 VBody integrated unit input valueAlwaysBATT voltage (BACKUP)10 — 15 VBody integrated unit input valueAlwaysIGN Voltage10 — 15 VBody integrated unit input val ...