Subaru Crosstrek Service Manual: Dtc p0970 pressure control solenoid "c" control circuit low

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P0970 PRESSURE CONTROL SOLENOID "C" CONTROL CIRCUIT LOW

DTC detecting condition:

Immediately at fault recognition

Trouble symptom:

Drivability getting worse.

CAUTION:

Use the check board when measuring the TCM terminal voltage and resistance.

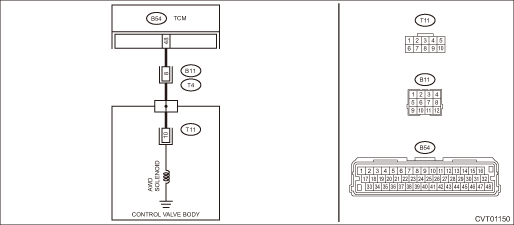

Wiring diagram:

CVT control system CVT Control System">

| STEP | CHECK | YES | NO |

1.CHECK HARNESS.

1) Turn the ignition switch to OFF.

2) Disconnect the TCM connector.

3) Disconnect the transmission connector.

4) Measure the resistance between TCM connector and chassis ground.

Connector & terminal

(B54) No. 48 — Chassis ground:

Is the resistance 1 M? or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0970 PRESSURE CONTROL SOLENOID "C" CONTROL CIRCUIT LOW">Go to Step 2.

Repair the short circuit of harness.

2.CHECK AWD SOLENOID.

Measure the resistance between transmission connector and transmission body.

Connector & terminal

(T4) No. 8 — Transmission body:

Is the resistance approx. 2 — 4.5 ?? (when cold)

Check for poor contact of connector, and if no fault is found, replace the TCM. Transmission Control Module (TCM)">

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0970 PRESSURE CONTROL SOLENOID "C" CONTROL CIRCUIT LOW">Go to Step 3.

3.CHECK HARNESS INSIDE TRANSMISSION.

CAUTION:

Start work after ATF cools down.

1) Remove the transmission valve cover.

2) Check for the harness pinch, damage.

Is there any fault in the harness?

Replace the transmission harness.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0970 PRESSURE CONTROL SOLENOID "C" CONTROL CIRCUIT LOW">Go to Step 4.

4.CHECK HARNESS INSIDE TRANSMISSION.

1) Disconnect the control valve body connector.

2) Measure the resistance between transmission connector and transmission body.

Connector & terminal

(T4) No. 8 — Transmission body:

Is the resistance 1 M? or more?

Replace the control valve body. Control Valve Body">

Replace the transmission harness.

1. OUTLINE OF DIAGNOSIS

• Detect the GND-output short in transfer solenoid circuit.

• Judge as NG if a ground short circuit is detected more than 10 times via the detection circuit for the transfer solenoid drive circuit.

2. EXECUTION CONDITION

Secondary Parameters | Execution condition |

Target duty cycle | 0% |

3. DIAGNOSTIC METHOD

If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Malfunction Criteria | Threshold Value |

Malfunction signal from solenoid driver IC | ≥ 10 count |

Time Needed for Diagnosis: Immediately

Malfunction Indicator Light Illumination: Does not illuminate.

Dtc p0967 pressure control solenoid "b" control circuit high

Dtc p0967 pressure control solenoid "b" control circuit high

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0967 PRESSURE CONTROL SOLENOID "B" CONTROL CIRCUIT HIGHDTC detecting conditi ...

Dtc p0971 pressure control solenoid "c" control circuit high

Dtc p0971 pressure control solenoid "c" control circuit high

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0971 PRESSURE CONTROL SOLENOID "C" CONTROL CIRCUIT HIGHDTC detecting conditi ...

Other materials:

Installing forward facing child restraint

WARNING

Before installing a child restraint

system, be sure to confirm that the

seatback is securely locked into

place. Otherwise, in an accident,

serious injury or death could result.

1. Shake the seatback slightly to confirm

that it is securely locked into place.

It is possible to check ...

Inspection

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Forward Clutch AssemblyINSPECTION• Check the forward clutch drum, internal gear, sun gear and forward clutch piston lip for wear or damage.• Inspect the drive plate facing for wear and damage.• Check the driven plate for discoloration ...

Caution

KEYLESS ACCESS WITH PUSH BUTTON START SYSTEM (DIAGNOSTICS) > General DescriptionCAUTION1. SRS AIRBAG SYSTEMThe airbag system wiring harness is routed near the keyless access with push button start system.CAUTION:• Do not use electrical test equipment on any wiring harnesses and connectors i ...