Subaru Crosstrek Service Manual: Dtc p0365 camshaft position sensor "b" circuit bank 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P0365 CAMSHAFT POSITION SENSOR "B" CIRCUIT BANK 1

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

• Engine stall

• Failure of engine to start

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

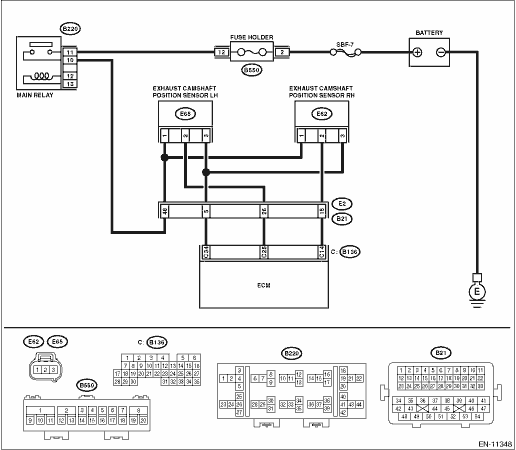

WIRING DIAGRAM:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK POWER SUPPLY OF CAMSHAFT POSITION SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from camshaft position sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between camshaft position sensor connector and engine ground.

Connector & terminal

(E62) No. 1 (+) — Engine ground (−):

Is the voltage 10 V or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0365 CAMSHAFT POSITION SENSOR "B" CIRCUIT BANK 1">Go to Step 2.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit or short circuit to ground in harness between main relay connector and camshaft position sensor connector

• Poor contact of coupling connector

2.CHECK HARNESS BETWEEN ECM AND CAMSHAFT POSITION SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Measure the resistance between ECM connector and camshaft position sensor connector.

Connector & terminal

(B136) No. 14 — (E62) No. 2:

(B136) No. 34 — (E62) No. 3:

Is the resistance less than 1 ??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0365 CAMSHAFT POSITION SENSOR "B" CIRCUIT BANK 1">Go to Step 3.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit in harness between ECM connector and camshaft position sensor connector

• Poor contact of coupling connector

3.CHECK HARNESS BETWEEN ECM AND CAMSHAFT POSITION SENSOR CONNECTOR.

Measure the resistance between camshaft position sensor connector and engine ground.

Connector & terminal

(E62) No. 2 — Engine ground:

Is the resistance 1 M? or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0365 CAMSHAFT POSITION SENSOR "B" CIRCUIT BANK 1">Go to Step 4.

Repair short circuit to ground in harness between ECM connector and camshaft position sensor connector.

4.CHECK HARNESS BETWEEN ECM AND CAMSHAFT POSITION SENSOR CONNECTOR.

Measure the voltage between camshaft position sensor connector and engine ground.

Connector & terminal

(E62) No. 2 (+) — Engine ground (−):

Is the voltage 5 V or more?

Repair the short circuit to power in the harness between ECM connector and camshaft position sensor connector.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0365 CAMSHAFT POSITION SENSOR "B" CIRCUIT BANK 1">Go to Step 5.

5.CHECK CONDITION OF CAMSHAFT POSITION SENSOR.

Is the camshaft position sensor installation bolt tightened securely?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0365 CAMSHAFT POSITION SENSOR "B" CIRCUIT BANK 1">Go to Step 6.

Tighten the camshaft position sensor installation bolt securely.

6.CHECK CAMSHAFT POSITION SENSOR.

Check the waveform of the camshaft position sensor. Engine Control Module (ECM) I/O Signal">

Is there any abnormality in waveform?

Replace the camshaft position sensor. Camshaft Position Sensor">

Repair the following item.

• Poor contact of ECM connector

• Poor contact of camshaft position sensor connector

• Poor contact of coupling connector

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the camshaft position sensor.

When there is no camshaft position signal input continuously, judge as NG.

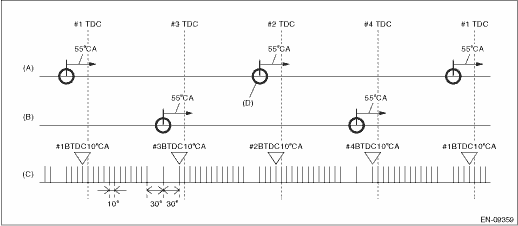

2. COMPONENT DESCRIPTION

(A) | Camshaft signal (RH) | (B) | Camshaft signal (LH) | (C) | Crankshaft signal |

(D) | Camshaft position signal: When normal, there will be 2 camshaft position signals for every 2 crankshaft revolutions. |

3. EXECUTION CONDITION

Secondary Parameters | Execution condition |

Battery voltage | ≥ 10.9 V |

Elapsed time after starting the engine | ≥ 200 ms |

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Judge as NG when no input of camshaft position sensor signal in TDC remains for 10 time(s).

Malfunction Criteria | Threshold Value |

Number of exhaust camshaft position sensor pulse during 0.5 crankshaft rev. | = 0 |

Time Needed for Diagnosis: TDC ? 10 time(s)

Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs.

Dtc p0354 ignition coil "d" primary control circuit/open

Dtc p0354 ignition coil "d" primary control circuit/open

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0354 IGNITION COIL "D" PRIMARY CONTROL CIRCUIT/OPENNOTE:For the diagnostic procedure, refer to DTC ...

Dtc p0366 camshaft position sensor "b" circuit range/performance bank 1

Dtc p0366 camshaft position sensor "b" circuit range/performance bank 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0366 CAMSHAFT POSITION SENSOR "B" CIRCUIT RANGE/PERFORMANCE BANK 1NOTE:For the diagnostic procedur ...

Other materials:

Removal

GLASS/WINDOWS/MIRRORS > Front Regulator and Motor AssemblyREMOVAL1. Disconnect the ground cable from battery and wait for at least 60 seconds before starting work. NOTE">2. Remove the trim panel - front door. Door Trim > REMOVAL">3. Remove the sealing cover - front door. Fro ...

Dtc p0716 input/turbine shaft speed sensor "a" circuit range/performance

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0716 INPUT/TURBINE SHAFT SPEED SENSOR "A" CIRCUIT RANGE/PERFORMANCEDTC detecting condition:Immediately at fault recognitionTrouble symptom:• No lock-up occurs.• Sho ...

Installation

LIGHTING SYSTEM > Front Fog Light BulbINSTALLATIONCAUTION:• After connecting the connector, make sure that the bulb is locked securely.• Install the mud guard - front so that the front end of the mud guard (b) comes outside the bumper face - front (a).Install each part in the reverse ...