Subaru Crosstrek Service Manual: Dtc p0336 crankshaft position sensor "a" circuit range/performance

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P0336 CRANKSHAFT POSITION SENSOR "A" CIRCUIT RANGE/PERFORMANCE

DTC detecting condition:

Detected when two consecutive driving cycles with fault occur.

Trouble symptom:

• Engine stall

• Failure of engine to start

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

| STEP | CHECK | YES | NO |

1.CHECK CONDITION OF CRANKSHAFT POSITION SENSOR.

Turn the ignition switch to OFF.

Is the crankshaft position sensor installation bolt tightened securely?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0336 CRANKSHAFT POSITION SENSOR "A" CIRCUIT RANGE/PERFORMANCE">Go to Step 2.

Tighten the crankshaft position sensor installation bolt securely. Crankshaft Position Sensor > INSTALLATION">

2.CHECK CRANKSHAFT POSITION SENSOR PLATE.

Is there crack or damage in the crankshaft position sensor plate teeth?

Replace the crankshaft position sensor plate. Cylinder Block">

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0336 CRANKSHAFT POSITION SENSOR "A" CIRCUIT RANGE/PERFORMANCE">Go to Step 3.

3.CHECK INSTALLATION CONDITION OF TIMING CHAIN.

Turn the crankshaft using ST, and align the alignment mark on crank sprocket with alignment mark on cylinder block.

Is the timing chain dislocated from its proper position?

Correct the installation condition of timing chain. Timing Chain Assembly">

Replace the crankshaft position sensor. Crankshaft Position Sensor">

1. OUTLINE OF DIAGNOSIS

Detect for faults in crankshaft position sensor output properties.

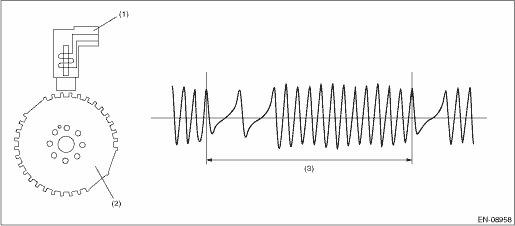

Judge as NG when there is a problem in the number of crankshaft signals for every revolution of crankshaft.

2. COMPONENT DESCRIPTION

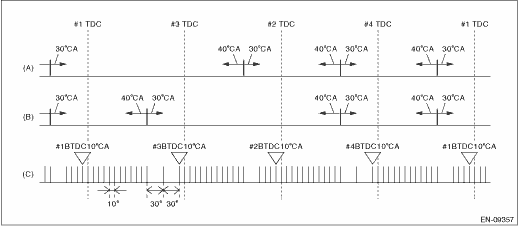

(A) | Camshaft signal (RH) | (B) | Camshaft signal (LH) | (C) | Crankshaft signal |

(1) | Crankshaft position sensor | (2) | Crankshaft position sensor plate | (3) | Crankshaft half-turn |

3. EXECUTION CONDITION

Secondary Parameters | Execution condition |

Battery voltage | ≥ 8 V |

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Judge as NG when the following conditions are established.

Malfunction Criteria | Threshold Value |

Amount of crank sensor signal during 1 rev of crankshaft | Not = 30 |

Time Needed for Diagnosis: 10 time(s) engine revs.

Malfunction Indicator Light Illumination: Illuminates when malfunction occurs in 2 continuous driving cycles.

Dtc p0335 crankshaft position sensor "a" circuit

Dtc p0335 crankshaft position sensor "a" circuit

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0335 CRANKSHAFT POSITION SENSOR "A" CIRCUITDTC DETECTING CONDITION:Immediately at fault recognitio ...

Dtc p0340 camshaft position sensor "a" circuit bank 1 or single sensor

Dtc p0340 camshaft position sensor "a" circuit bank 1 or single sensor

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0340 CAMSHAFT POSITION SENSOR "A" CIRCUIT BANK 1 OR SINGLE SENSORDTC DETECTING CONDITION:Immediate ...

Other materials:

Synthetic oil

You should use synthetic engine oil that

meets the same requirements given for

conventional engine oil. When using

synthetic oil, you must use oil of the same

classification, viscosity and grade shown

in this Owner's Manual. Refer to "Engine

oil" F12-4. Also, you must follow the oil

and filte ...

Vehicle Dynamics Control OFF switch

Vehicle Dynamics Control OFF switch

Vehicle Dynamics Control OFF switch

Pressing the Vehicle Dynamics Control

OFF switch deactivates the Vehicle Dynamics

Control system.

Creating an adequate driving wheel slip by

deactivating the Vehicle Dynamics Control

system temporarily may help to e ...

Dtc p0301 cylinder 1 misfire detected

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0301 CYLINDER 1 MISFIRE DETECTEDNOTE:For the diagnostic procedure, refer to DTC P0304. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0304 CYLINDER 4 MISFIRE DETECTED">1. OUTLINE O ...