Subaru Crosstrek Service Manual: Dtc p0335 crankshaft position sensor "a" circuit

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P0335 CRANKSHAFT POSITION SENSOR "A" CIRCUIT

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

• Engine stall

• Failure of engine to start

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

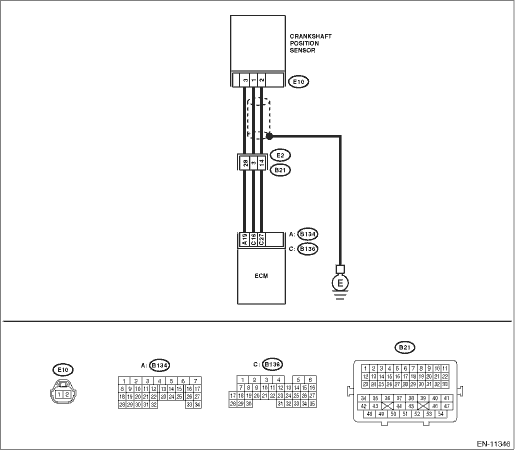

WIRING DIAGRAM:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK INSTALLATION CONDITION OF CRANKSHAFT POSITION SENSOR.

Is the crankshaft position sensor installation bolt tightened securely?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0335 CRANKSHAFT POSITION SENSOR "A" CIRCUIT">Go to Step 2.

Tighten the crankshaft position sensor installation bolt securely. Crankshaft Position Sensor > INSTALLATION">

2.CHECK CRANKSHAFT POSITION SENSOR.

1) Turn the ignition switch to OFF.

2) Remove the crankshaft position sensor.

3) Measure the resistance between terminals of crankshaft position sensor.

Terminals

No. 1 — No. 2:

Is the resistance between 1 and 4 k??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0335 CRANKSHAFT POSITION SENSOR "A" CIRCUIT">Go to Step 3.

Replace the crankshaft position sensor. Crankshaft Position Sensor">

3.CHECK HARNESS BETWEEN ECM AND CRANKSHAFT POSITION SENSOR CONNECTOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness between ECM connector and crankshaft position sensor connector.

Connector & terminal

(B136) No. 16 — (E10) No. 1:

(B136) No. 27 — (E10) No. 2:

Is the resistance less than 1 ??

Repair the poor contact of ECM and crankshaft position sensor connector.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit in harness between ECM connector and crankshaft position sensor connector

• Poor contact of coupling connector

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the crankshaft position sensor.

Judge as NG when the crank signal is not input even though the starter was rotated.

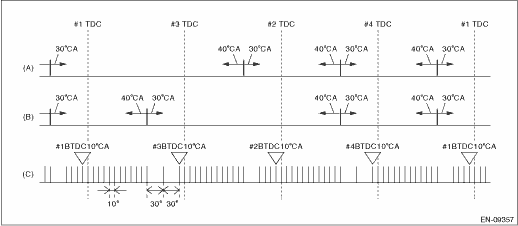

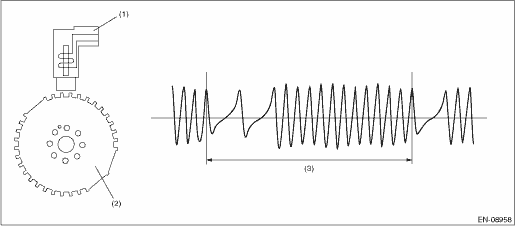

2. COMPONENT DESCRIPTION

(A) | Camshaft signal (RH) | (B) | Camshaft signal (LH) | (C) | Crankshaft signal |

(1) | Crankshaft position sensor | (2) | Crankshaft position sensor plate | (3) | Crankshaft half-turn |

3. EXECUTION CONDITION

Secondary Parameters | Execution condition |

Battery voltage | ≥ 8 V |

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Malfunction Criteria | Threshold Value |

Crankshaft position sensor signal | Not detected |

Time Needed for Diagnosis: 3000 ms

Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs.

Dtc p0328 knock/combustion vibration sensor 1 circuit high bank 1 or single sensor

Dtc p0328 knock/combustion vibration sensor 1 circuit high bank 1 or single sensor

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0328 KNOCK/COMBUSTION VIBRATION SENSOR 1 CIRCUIT HIGH BANK 1 OR SINGLE SENSORDTC DETECTING CONDITION:Immedia ...

Dtc p0336 crankshaft position sensor "a" circuit range/performance

Dtc p0336 crankshaft position sensor "a" circuit range/performance

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0336 CRANKSHAFT POSITION SENSOR "A" CIRCUIT RANGE/PERFORMANCEDTC detecting condition:Detected when ...

Other materials:

Dtc b2282 vehicle speed signal correlation

KEYLESS ACCESS WITH PUSH BUTTON START SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B2282 VEHICLE SPEED SIGNAL CORRELATIONDTC detecting condition:When the vehicle speed signal transmitted from VDC via solid line and the vehicle speed signal transmitted via CAN ...

Installation

ENTERTAINMENT > AntennaINSTALLATIONCAUTION:• After installing the center grille assembly, check that the air vent grille of the center grille assembly is inserted correctly into the air vent duct.• Before handling the airbag system components, always refer to “CAUTION” of ...

Installation

BRAKE > Brake HoseINSTALLATION1. FRONT BRAKE HOSE1. Secure the brake hose to strut mount.Tightening torque:Brake hose: 33 N·m (3.36 kgf-m, 24.3 ft-lb)2. Connect the brake hose to the front caliper body assembly using a new gasket.Tightening torque:Union bolt: 26 N·m (2.65 kgf-m, 19. ...