Subaru Crosstrek Service Manual: Dtc p014c a/f / o2 sensor slow response - rich to lean bank 1 sensor 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P014C A/F / O2 SENSOR SLOW RESPONSE - RICH TO LEAN BANK 1 SENSOR 1

DTC DETECTING CONDITION:

Detected when two consecutive driving cycles with fault occur.

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

| STEP | CHECK | YES | NO |

1.CHECK EXHAUST SYSTEM.

NOTE:

Check the following items.

• Loose installation of front portion of exhaust pipe onto cylinder heads

• Loose connection between front exhaust pipe and front catalytic converter

• Damage of exhaust pipe resulting in a hole

Is there any fault in exhaust system?

Repair the exhaust system.

Replace the front oxygen (A/F) sensor. Front Oxygen (A/F) Sensor">

1. OUTLINE OF DIAGNOSIS

Detect the slow response of front oxygen (A/F) sensor.

For diagnosis, detect the trouble by processing the λ waveform in normal driving without forcibly changing the target air fuel ratio.

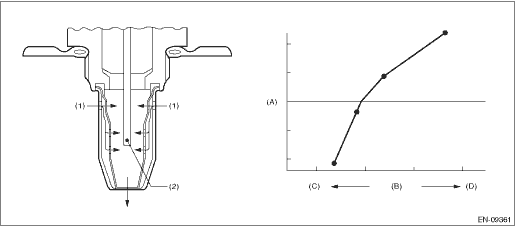

2. COMPONENT DESCRIPTION

(A) | Electromotive force | (B) | Air fuel ratio | (C) | Rich |

(D) | Lean | ||||

(1) | Exhaust gas | (2) | Zirconia element oxygen |

3. EXECUTION CONDITION

Secondary parameters | Execution condition |

Battery voltage | ≥ 10.9 V |

Barometric pressure | ≥ 75.1 kPa (563 mmHg, 22.2 inHg) |

Duration of main feedback | ≥ 3000 ms |

Engine speed | ≥ 1000 rpm |

Amount of intake air | ≥ 10 g/s (0.35 oz/s) (CVT model) ≥ 10 g/s (0.35 oz/s) (MT model) |

4. GENERAL DRIVING CYCLE

Perform diagnosis only once in a city driving including normal acceleration and deceleration.

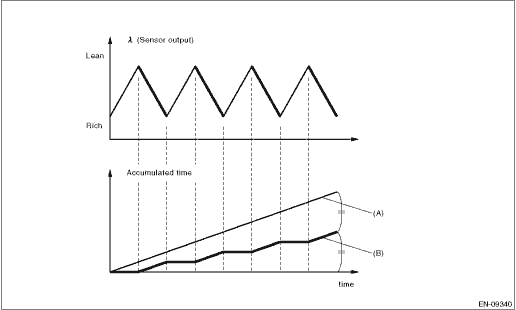

5. DIAGNOSTIC METHOD 1

Detect the malfunction by checking “Cumulative value of time when λ changes from lean > rich” in comparison to “Time during which diagnosis is in progress”.

(A) | Time during which diagnosis is in progress | (B) | Cumulative value of time when λ changes from lean > rich |

Judge as NG when the following conditions are established.

Diagnosis (CVT model)

Malfunction Criteria | Threshold Value | DTC |

(Cumulative value of time when λ changes from lean > rich) / (Time during which diagnosis is in progress) | < 0.39 | P014C |

and | ||

Average value of time necessary for λ to inverse the air fuel ratio to Lean > Rich > Lean | < 30 ms | |

(Cumulative value of time when λ changes from rich > lean) / (Time during which diagnosis is in progress) | > 0.63 | P014D |

and | ||

Average value of time necessary for λ to inverse the air fuel ratio to Rich > Lean > Rich | > 20 ms |

Diagnosis (MT model)

Malfunction Criteria | Threshold Value | DTC |

(Cumulative value of time when λ changes from lean > rich) / (Time during which diagnosis is in progress) | < 0.4 | P014C |

and | ||

Average value of time necessary for λ to inverse the air fuel ratio to Lean > Rich > Lean | < 25 ms | |

(Cumulative value of time when λ changes from rich > lean) / (Time during which diagnosis is in progress) | > 0.6 | P014D |

and | ||

Average value of time necessary for λ to inverse the air fuel ratio to Rich > Lean > Rich | > 5 ms |

Diagnosis (CVT model)

Time Needed for Diagnosis: 90 seconds

Diagnosis (MT model)

Time Needed for Diagnosis: 60 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunction occurs in 2 continuous driving cycles.

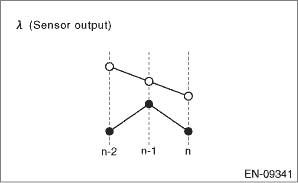

6. DIAGNOSTIC METHOD 2

Detect the malfunction by the cumulative value obtained from the amount of variation in λ change.

Judge as NG when the following conditions are established.

Malfunction Criteria | Threshold Value | DTC |

Cumulative value obtained from the amount of variation in λ change | < Value from Map | P014C and P014D |

Cumulative value obtained from the amount of variation in λ | 0.00 | 3.50 |

Cumulative value obtained from the amount of variation in λ change | 0.00 | 3.50 |

Cumulative value obtained from the amount of variation in λ | 0.00 | 3.50 |

Cumulative value obtained from the amount of variation in λ change | 0.00 | 3.50 |

Diagnosis (CVT model)

Time needed for diagnosis: 90 seconds

Diagnosis (MT model)

Time needed for diagnosis: 60 seconds

Malfunction indicator light illumination: Illuminates when malfunction occurs in 2 continuous driving cycles.

Dtc p0141 o2 sensor heater circuit bank 1 sensor 2

Dtc p0141 o2 sensor heater circuit bank 1 sensor 2

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0141 O2 SENSOR HEATER CIRCUIT BANK 1 SENSOR 2Refer to DTC P0037 for diagnostic procedure. Diagnostic Proced ...

Dtc p014d a/f / o2 sensor slow response - lean to rich bank 1 sensor 1

Dtc p014d a/f / o2 sensor slow response - lean to rich bank 1 sensor 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P014D A/F / O2 SENSOR SLOW RESPONSE - LEAN TO RICH BANK 1 SENSOR 1NOTE:For the diagnostic procedure, refer to ...

Other materials:

Installation

FRONT SUSPENSION > Front StrutINSTALLATION1. Install the strut mount - front at the upper side of the strut to the body, and tighten it with new flange nuts.Tightening torque:20 N·m (2.04 kgf-m, 14.8 ft-lb)2. Align alignment marks on the camber adjusting bolt and strut.Using new self-locki ...

Dtc c2521 motor malfunction

POWER ASSISTED SYSTEM (POWER STEERING) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C2521 MOTOR MALFUNCTIONTrouble symptom:• The steering wheel operation feels heavy.• STEERING warning light illuminates.Wiring diagram:Electric power steering system Elect ...

Automatic Locking Retractor/Emergency Locking Retractor (ALR/ELR)

Each passenger's seatbelt has an Automatic

Locking Retractor/Emergency Locking

Retractor (ALR/ELR). The Automatic

Locking Retractor/Emergency Locking

Retractor normally functions as an Emergency

Locking Retractor (ELR). The ALR/

ELR has an additional locking mode

"Automatic Locking Retractor ...