Subaru Crosstrek Service Manual: Dtc p0013 "b" camshaft position actuator control circuit/open bank 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P0013 "B" CAMSHAFT POSITION ACTUATOR CONTROL CIRCUIT/OPEN BANK 1

DTC detecting condition:

Immediately at fault recognition

Trouble symptom:

Improper idling

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

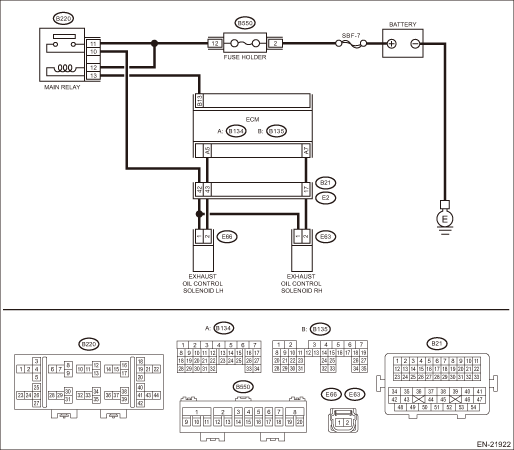

Wiring diagram:

Engine electrical system Power Supply Circuit">

| STEP | CHECK | YES | NO |

1.CHECK OUTPUT SIGNAL OF ECM.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM connector and chassis ground.

Connector & terminal

(B134) No. 7 (+) — Chassis ground (−):

Is the voltage 10 V or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0013 "B" CAMSHAFT POSITION ACTUATOR CONTROL CIRCUIT/OPEN BANK 1">Go to Step 2.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0013 "B" CAMSHAFT POSITION ACTUATOR CONTROL CIRCUIT/OPEN BANK 1">Go to Step 3.

2.CHECK FOR POOR CONTACT.

Check for poor contact of ECM connector.

Is there poor contact of ECM connector?

Repair the poor contact of ECM connector.

Even if DTC is detected, the circuit has returned to a normal condition at this time. Reproduce the failure, and then perform the diagnosis again.

NOTE:

In this case, temporary poor contact of connector, temporary open or short circuit of harness may be the cause.

3.CHECK POWER SUPPLY TO THE EXHAUST OIL CONTROL SOLENOID RH.

Measure the voltage between exhaust oil control solenoid RH connector and engine ground.

Connector & terminal

(E63) No. 1 (+) — Engine ground (−):

Is the voltage 10 V or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0013 "B" CAMSHAFT POSITION ACTUATOR CONTROL CIRCUIT/OPEN BANK 1">Go to Step 4.

Repair the power supply circuit.

4.CHECK HARNESS BETWEEN ECM AND EXHAUST OIL CONTROL SOLENOID RH CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connector from the exhaust oil control solenoid RH.

4) Measure the resistance between exhaust oil control solenoid RH connector and engine ground.

Connector & terminal

(E63) No. 2 — Engine ground:

Is the resistance 1 M? or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0013 "B" CAMSHAFT POSITION ACTUATOR CONTROL CIRCUIT/OPEN BANK 1">Go to Step 5.

Repair the short circuit to ground in harness between ECM connector and exhaust oil control solenoid RH connector.

5.CHECK HARNESS BETWEEN ECM AND EXHAUST OIL CONTROL SOLENOID RH CONNECTOR.

Measure the resistance of harness between ECM connector and exhaust oil control solenoid RH.

Connector & terminal

(B134) No. 7 — (E63) No. 2:

Is the resistance less than 1 ??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0013 "B" CAMSHAFT POSITION ACTUATOR CONTROL CIRCUIT/OPEN BANK 1">Go to Step 6.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit in harness between ECM connector and exhaust oil control solenoid RH connector

• Poor contact of coupling connector

6.CHECK EXHAUST OIL CONTROL SOLENOID RH.

Measure the resistance between exhaust oil control solenoid RH terminals.

Terminals

No. 1 — No. 2:

Is the resistance 6 — 12 ??

Repair the poor contact of exhaust oil control solenoid RH connector.

Replace the exhaust oil control solenoid RH. Oil Control Solenoid">

1. OUTLINE OF DIAGNOSIS

Detect open or short circuit of the oil control solenoid.

Judge as NG when the current is small even though the duty signal is large.

2. EXECUTION CONDITION

Secondary Parameters | Execution condition |

Battery voltage | ≥ 10.9 V |

Oil control solenoid control duty | ≥ 99.61 % |

3. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

4. DIAGNOSTIC METHOD

If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Malfunction Criteria | Threshold Value |

Oil control solenoid control present current | < 0.306 A |

Time Needed for Diagnosis: 2000 ms

Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs.

Dtc p0011 "a" camshaft position - timing over-advanced or system performance bank 1

Dtc p0011 "a" camshaft position - timing over-advanced or system performance bank 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0011 "A" CAMSHAFT POSITION - TIMING OVER-ADVANCED OR SYSTEM PERFORMANCE BANK 1DTC detecting condit ...

Dtc p0014 "b" camshaft position - timing over-advanced or system performance bank 1

Dtc p0014 "b" camshaft position - timing over-advanced or system performance bank 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0014 "B" CAMSHAFT POSITION - TIMING OVER-ADVANCED OR SYSTEM PERFORMANCE BANK 1DTC detecting condit ...

Other materials:

Dtc p0016 crankshaft position - camshaft position correlation bank 1 sensor a

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0016 CRANKSHAFT POSITION - CAMSHAFT POSITION CORRELATION BANK 1 SENSOR ADTC detecting condition:Detected when two consecutive driving cycles with fault occur.Trouble symptom:• Engine stall• Improp ...

Procedure

LAN SYSTEM (DIAGNOSTICS) > CAN Communication Circuit CheckPROCEDURENOTE:• When measuring the resistance of CAN communication circuit, measure it in sleep status.To enter sleep status– With ignition switch OFF and key or switch operation stopped, keep the doors, trunk, and rear gate all c ...

List

TELEMATICS SYSTEM (DIAGNOSTICS) > System Operation Check ModeLISTSystem operation check modeNoteGREEN LED LightingGREEN LED illuminates/flashes/goes off.GREEN LED FlashingGREEN LED OFFRED LED LightingRED LED illuminates/flashes/goes off.RED LED FlashingRED LED OFFSpeaker ONOutputs to speaker. ...