Subaru Crosstrek Service Manual: Component

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > General Description

COMPONENT

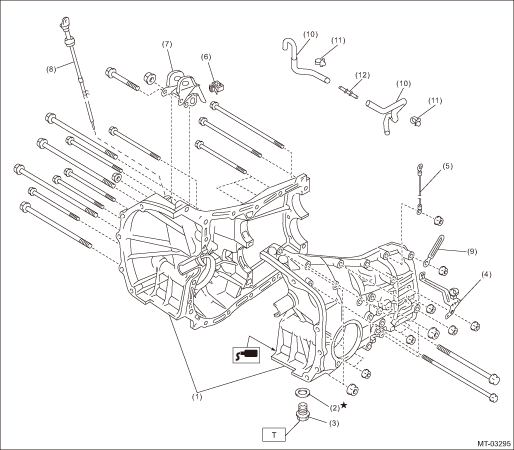

1. TRANSMISSION CASE

(1) | Transmission case ASSY | (7) | Pitching stopper bracket | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Gasket | (8) | Oil level gauge | T: | 44 (4.5, 32.5) (aluminum gasket, silver) |

(3) | Drain plug | (9) | Harness clip | 70 (7.1, 51.6) (copper gasket, brown) | |

(4) | Harness bracket | (10) | Air breather hose | 70 (7.1, 51.6) (metal gasket, black) | |

(5) | Transmission radio ground cord | (11) | Clip | ||

(6) | Clamp | (12) | Hose connector | ||

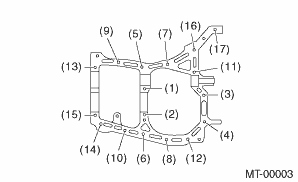

Transmission case tightening torque

Bolt No.

Bolt size

mm

Tightening torque: N·m (kgf-m, ft-lb)

(5) — (15)

8

25 (2.5, 18.4)

(1) — (4)

(16), (17)

10

39 (4.0, 28.8)

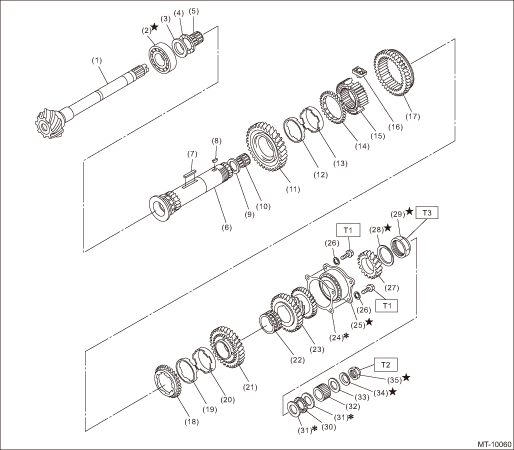

2. DRIVE PINION SHAFT ASSEMBLY

(1) | Drive pinion shaft | (15) | 1st-2nd synchronizer hub | (29) | Lock nut |

(2) | Roller bearing | (16) | 1st-2nd shifting insert | (30) | Thrust bearing |

(3) | Washer | (17) | Reverse driven gear | (31) | Adjusting washer |

(4) | Thrust bearing | (18) | Outer baulk ring | (32) | Differential bevel gear sleeve |

(5) | Needle bearing | (19) | Synchro cone | (33) | Washer |

(6) | Driven shaft | (20) | Inner baulk ring | (34) | Lock washer |

(7) | Key | (21) | 2nd driven gear | (35) | Lock nut |

(8) | Woodruff key | (22) | 2nd driven gear bushing | ||

(9) | Drive pinion collar | (23) | 3rd-4th driven gear | Tightening torque: N·m (kgf-m, ft-lb) | |

(10) | Needle bearing | (24) | Drive pinion shim | T1: | 30 (3.1, 22.1) |

(11) | 1st driven gear | (25) | Double taper roller bearing | T2: | 120 (12.2, 88.5) |

(12) | Inner baulk ring | (26) | Spring washer | T3: | 260 (26.5, 191.8) |

(13) | Synchro cone | (27) | 5th driven gear | ||

(14) | Outer baulk ring | (28) | Lock washer | ||

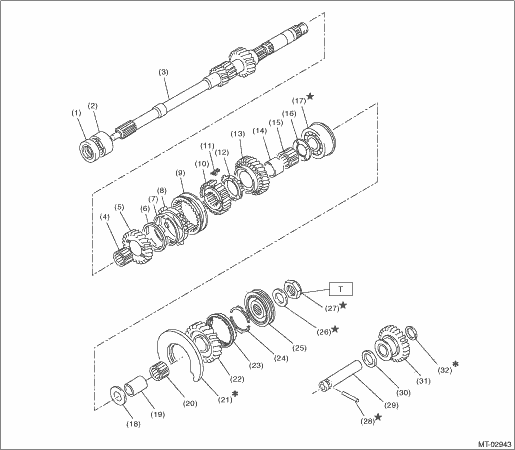

3. MAIN SHAFT ASSY

(1) | Oil seal | (14) | 4th needle bearing race | (26) | Lock washer |

(2) | Needle bearing | (15) | 4th needle bearing | (27) | Lock nut |

(3) | Main shaft | (16) | 4th gear thrust washer | (28) | Straight pin |

(4) | 3rd needle bearing | (17) | Double ball bearing | (29) | Reverse idler gear shaft |

(5) | 3rd drive gear | (18) | 5th gear thrust washer | (30) | Reverse idler gear washer |

(6) | Inner baulk ring | (19) | 5th needle bearing race | (31) | Reverse idler gear |

(7) | 3rd synchro cone | (20) | 5th needle bearing | (32) | Adjusting washer |

(8) | Outer baulk ring | (21) | Main shaft rear plate | ||

(9) | 3rd-4th coupling sleeve | (22) | 5th drive gear | Tightening torque: N·m (kgf-m, ft-lb) | |

(10) | 3rd-4th synchronizer hub | (23) | 5th baulk ring | T: | 120 (12.2, 88.5) |

(11) | 3rd-4th shifting insert | (24) | Baulk lever | ||

(12) | 4th baulk ring | (25) | 5th hub & sleeve No. 2 | ||

(13) | 4th drive gear | ||||

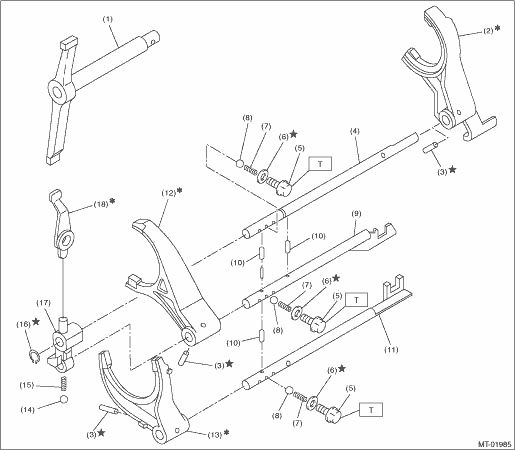

4. SHIFTER FORK AND SHIFTER ROD

(1) | Shifter arm | (8) | Check ball | (15) | Checking ball spring |

(2) | 5th shifter fork | (9) | 3rd-4th fork rod | (16) | Snap ring (outer) |

(3) | Straight pin | (10) | Interlock plunger | (17) | Reverse fork rod arm |

(4) | Reverse fork rod | (11) | 1st-2nd fork rod | (18) | Reverse shifter lever |

(5) | Checking ball plug | (12) | 3rd-4th shifter fork | ||

(6) | Gasket | (13) | 1st-2nd shifter fork | Tightening torque: N·m (kgf-m, ft-lb) | |

(7) | Checking ball spring | (14) | Check ball | T: | 20 (2.0, 14.8) |

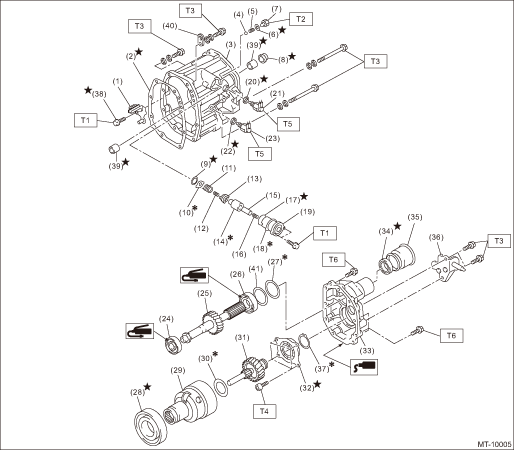

5. TRANSFER CASE AND EXTENSION

(1) | Oil guide | (18) | Adjusting select shim | (34) | Oil seal |

(2) | Gasket | (19) | Reverse check sleeve | (35) | Dust cover |

(3) | Transfer case | (20) | Gasket | (36) | Shift bracket |

(4) | Ball | (21) | Neutral position switch | (37) | Snap ring |

(5) | Reverse accent spring | (22) | Gasket | (38) | Precoat bolt |

(6) | Gasket | (23) | Back-up light switch | (39) | Roller bearing |

(7) | Plug | (24) | Taper roller bearing (transfer case side) | (40) | Transmission hanger |

(8) | Oil seal | (25) | Transfer driven gear | (41) | Dish plate |

(9) | Snap ring (inner) | (26) | Taper roller bearing (extension case side) | ||

(10) | Reverse check plate | (27) | Adjusting washer | Tightening torque: N·m (kgf-m, ft-lb) | |

(11) | Reverse check spring | (28) | Ball bearing | T1: | 6.4 (0.7, 4.7) |

(12) | Reverse return spring | (29) | Center differential | T2: | 9.75 (1.0, 7.2) |

(13) | Reverse check cam | (30) | Adjusting washer | T3: | 24.5 (2.5, 18.1) |

(14) | Reverse accent shaft | (31) | Transfer drive gear | T4: | 26 (2.7, 19.2) |

(15) | Return spring cap | (32) | Ball bearing | T5: | 32.3 (3.3, 23.8) |

(16) | Return spring | (33) | Extension case | T6: | 40 (4.1, 29.5) |

(17) | O-ring | ||||

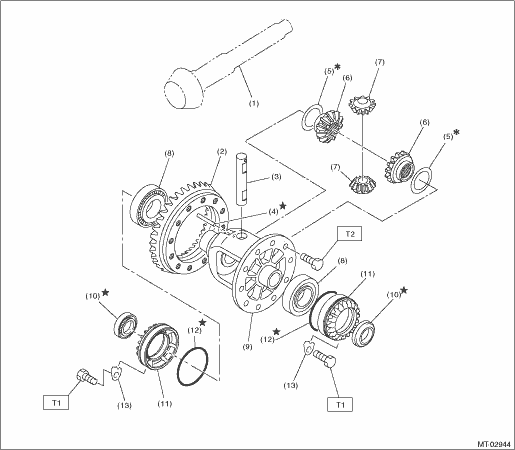

6. FRONT DIFFERENTIAL

(1) | Drive pinion shaft | (7) | Differential bevel pinion | (13) | Retainer lock plate |

(2) | Hypoid driven gear | (8) | Taper roller bearing | ||

(3) | Pinion shaft | (9) | Differential case | Tightening torque: N·m (kgf-m, ft-lb) | |

(4) | Straight pin | (10) | Oil seal | T1: | 25 (2.5, 18.4) |

(5) | Adjusting washer | (11) | Differential side retainer | T2: | 62 (6.3, 45.7) |

(6) | Differential bevel gear | (12) | O-ring | ||

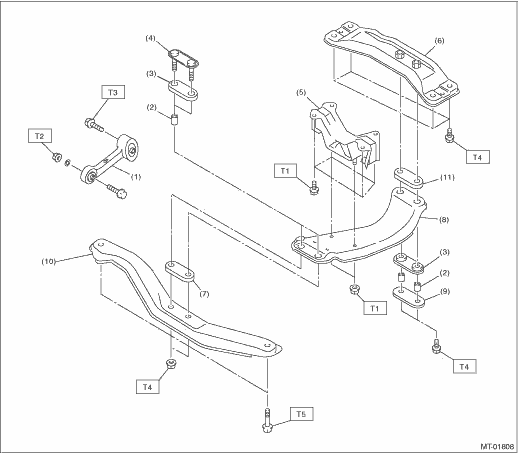

7. TRANSMISSION MOUNTING

(1) | Pitching stopper | (7) | Upper cushion rubber | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Spacer | (8) | Center crossmember | T1: | 35 (3.6, 25.8) |

(3) | Lower cushion rubber | (9) | Rear plate | T2: | 50 (5.1, 36.9) |

(4) | Front plate | (10) | Front crossmember | T3: | 58 (5.9, 42.8) |

(5) | Transmission cushion rubber | (11) | Rear cushion rubber | T4: | 70 (7.1, 51.6) |

(6) | Rear crossmember | T5: | 140 (14.3, 103.3) | ||

Specification

Specification

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > General DescriptionSPECIFICATION1. MANUAL TRANSMISSION AND DIFFERENTIALModelCrosstrek modelType5-forward speeds and 1-reverse (all stage with synchromesh ...

Preparation tool

Preparation tool

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > General DescriptionPREPARATION TOOL1. SPECIAL TOOLILLUSTRATIONTOOL NUMBERDESCRIPTIONREMARKS399411700ACCENT BALL INSTALLERUsed for installing reverse fork ...

Other materials:

Using aha application

1. When the top screen is displayed,

touch the station key.

Example of the main screen

2. Select the desired station from the list.

The selected station is displayed.

NOTE

The following operations are not

available on this system. Perform these

operations on the smartphone.

Add ...

Driver's seatbelt

The driver's seatbelt has a shoulder belt

pretensioner.

The pretensioner sensor also serves as

follows.

SRS frontal airbag sensor

Side impact sensor

Front door impact sensor

Rollover sensor

If the sensor detects a certain predetermined

amount of force during frontal or

side col ...

Dtc p2610 ecm/pcm engine off timer performance

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2610 ECM/PCM ENGINE OFF TIMER PERFORMANCEDTC DETECTING CONDITION:Detected when two consecutive driving cycles with fault occur.CAUTION:After servicing or replacing faulty parts, perform Clear Memory Mode Cle ...