Subaru Crosstrek Service Manual: Component

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > General Description

COMPONENT

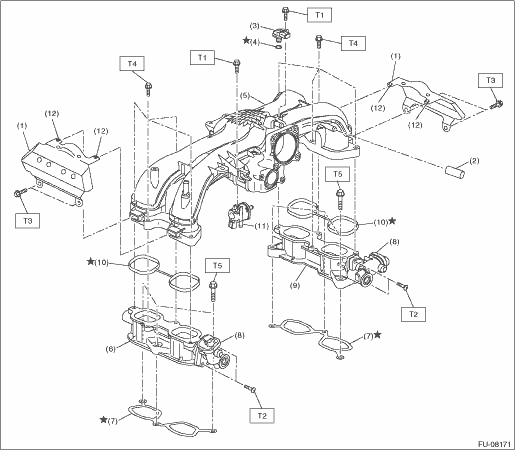

1. INTAKE MANIFOLD 1

(1) | Intake manifold protector | (7) | Gasket | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Cap | (8) | Tumble generator valve actuator | T1: | 3.4 (0.3, 2.5) |

(3) | Manifold absolute pressure sensor | (9) | Tumble generator valve RH | T2: | 6 (0.6, 4.4) |

(4) | O-ring | (10) | Gasket | T3: | 6.4 (0.7, 4.7) |

(5) | Intake manifold | (11) | Purge control solenoid valve | T4: | 8.3 (0.8, 6.1) |

(6) | Tumble generator valve LH | (12) | Cushion | T5: | 25 (2.5, 18.4) |

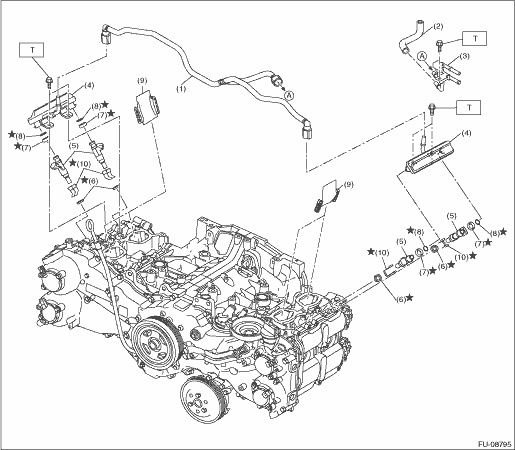

2. INTAKE MANIFOLD 2

(1) | Fuel delivery pipe | (6) | Seal ring | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Vacuum hose | (7) | Rubber | T: | 6.4 (0.7, 4.7) |

(3) | Fuel pipe A | (8) | O-ring | ||

(4) | Fuel pipe B | (9) | Cylinder head plate | ||

(5) | Fuel injector | (10) | Fuel injector holder | ||

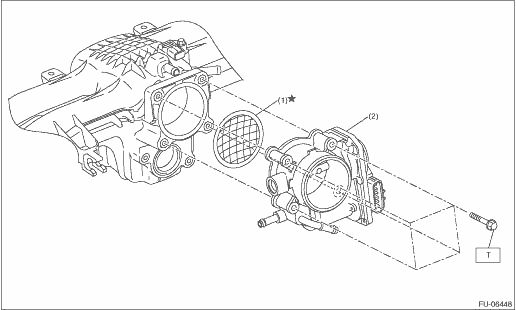

3. THROTTLE BODY

(1) | Gasket | (2) | Throttle body | Tightening torque: N·m (kgf-m, ft-lb) | |

T: | 8 (0.8, 5.9) | ||||

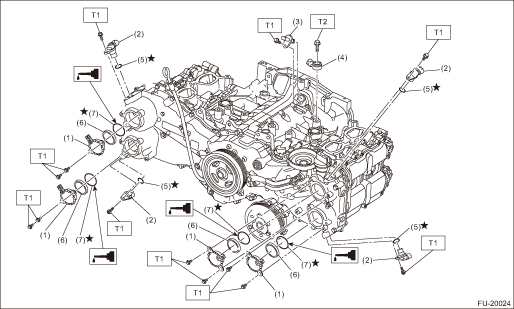

4. CRANKSHAFT POSITION, CAMSHAFT POSITION AND KNOCK SENSORS

(1) | Oil control solenoid | (5) | O-ring | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Camshaft position sensor | (6) | Back-up ring | T1: | 6.4 (0.7, 4.7) |

(3) | Crankshaft position sensor | (7) | O-ring | T2: | 24 (2.4, 17.7) |

(4) | Knock sensor | ||||

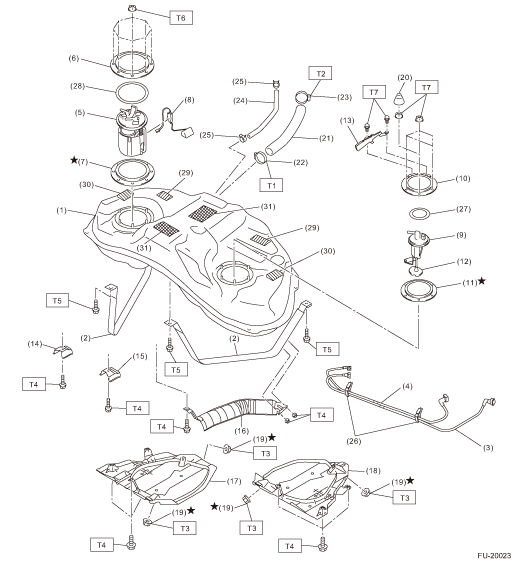

5. FUEL TANK

(1) | Fuel tank | (15) | Stopper LH | (29) | Cushion |

(2) | Fuel tank band | (16) | Heat shield cover | (30) | Cushion |

(3) | Delivery tube | (17) | Fuel tank protector RH | (31) | Cushion |

(4) | Jet pump tube | (18) | Fuel tank protector LH | ||

(5) | Fuel pump ASSY | (19) | Self-locking nut | Tightening torque: N·m (kgf-m, ft-lb) | |

(6) | Fuel pump upper plate | (20) | Rubber cap | T1: | 2 (0.2, 1.5) |

(7) | Fuel pump gasket | (21) | Fuel filler hose | T2: | 2.5 (0.3, 1.8) |

(8) | Fuel level sensor | (22) | Clamp | T3: | 9 (0.9, 6.6) |

(9) | Fuel sub level sensor | (23) | Clamp | T4: | 18 (1.8, 13.3) |

(10) | Fuel sub level sensor upper plate | (24) | Air vent hose | T5: | 33 (3.4, 24.3) |

(11) | Fuel sub level sensor gasket | (25) | Clip | T6: | Fuel Pump > INSTALLATION"> |

(12) | Fuel sub level sensor filter | (26) | Tube clamp | T7: | Fuel Sub Level Sensor > INSTALLATION"> |

(13) | Fuel sub level sensor protector | (27) | Fuel sub level sensor upper plate cushion | ||

(14) | Stopper RH | (28) | Fuel pump upper plate cushion | ||

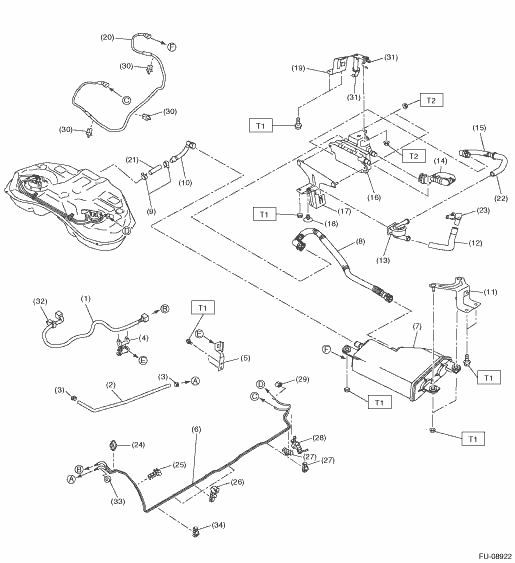

6. FUEL LINE

(1) | Fuel delivery tube | (14) | Drain tube B | (27) | Pipe clamp |

(2) | Evaporation hose | (15) | Drain tube C | (28) | Pipe clamp |

(3) | Clip | (16) | Leak check valve ASSY | (29) | Fuel pipe rear grommet |

(4) | Hose clamp | (17) | Leak check valve bracket A | (30) | Pipe clamp |

(5) | Hose clamp bracket | (18) | Clip | (31) | Tube clamp |

(6) | Fuel pipe ASSY | (19) | Leak check valve bracket B | (32) | Tube clamp |

(7) | Canister | (20) | Purge pipe | (33) | Bushing |

(8) | Drain tube A | (21) | Vent hose | (34) | Pipe clamp |

(9) | Clip | (22) | Drain hose | ||

(10) | Vent tube | (23) | Connector | Tightening torque: N·m (kgf-m, ft-lb) | |

(11) | Canister bracket | (24) | Fuel pipe front grommet | T1: | 7.5 (0.8, 5.5) |

(12) | Intake hose | (25) | Pipe clamp | T2: | 18 (1.8, 13.3) |

(13) | Drain separator | (26) | Pipe clamp | ||

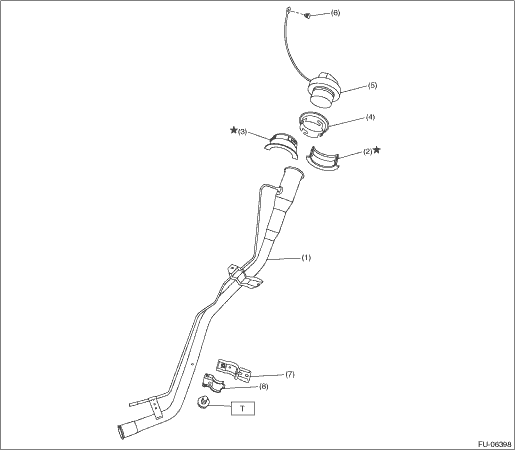

7. FUEL FILLER PIPE

(1) | Fuel filler pipe ASSY | (5) | Fuel filler cap | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Neck holder A | (6) | Clip | T: | 7.5 (0.8, 5.5) |

(3) | Neck holder B | (7) | Upper bracket | ||

(4) | Fuel filler pipe protector | (8) | Lower bracket | ||

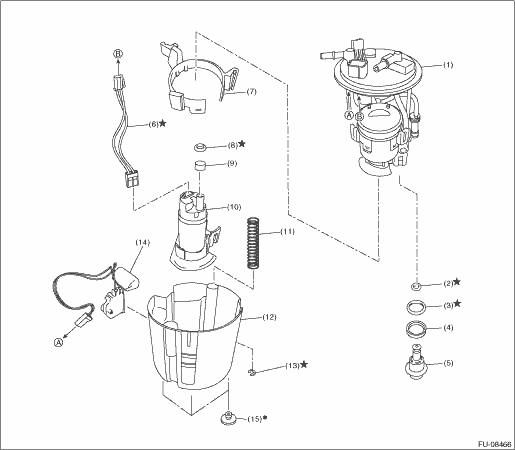

8. FUEL PUMP

(1) | Fuel filter ASSY | (6) | Connector cable | (11) | Spring |

(2) | O-ring | (7) | Fuel pump holder | (12) | Fuel chamber ASSY |

(3) | O-ring | (8) | O-ring | (13) | Clip |

(4) | Back-up ring | (9) | Spacer | (14) | Fuel level sensor |

(5) | Pressure regulator | (10) | Fuel pump | (15) | Cushion |

* When removing the cushion from the fuel chamber assembly, replace it with a new part. | |||||

Specification

Specification

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > General DescriptionSPECIFICATIONFuel tankCapacity60 L (15.9 US gal, 13.2 Imp gal)LocationUnder rear seatFuel pumpTypeImpellerShutoff discharge pressure750 kPa ...

Preparation tool

Preparation tool

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > General DescriptionPREPARATION TOOL1. SPECIAL TOOLILLUSTRATIONTOOL NUMBERDESCRIPTIONREMARKS18471AA000FUEL PIPE ADAPTERUsed for draining fuel. — SUBARU SELECT ...

Other materials:

Tire pressure warning light does not come off

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS) > Tire Pressure Warning Light / Trouble Indicator Light Illumination PatternTIRE PRESSURE WARNING LIGHT DOES NOT COME OFFDETECTING CONDITION:• Defective combination meter• Tires pressure drop• Transmitter ID not registeredTROUBLE SYM ...

List of diagnostic trouble code (dtc) List

POWER ASSISTED SYSTEM (POWER STEERING) (DIAGNOSTICS) > List of Diagnostic Trouble Code (DTC)LISTDTCItemContent of diagnosisNoteNoneWithout DTCNormal Subaru Select Monitor > INSPECTION">“Assist limitation” is displayed in the current data «EPS operating condition».Assist l ...

Installation

BRAKE > Stop Light SwitchINSTALLATION1. BULB TYPE1. Install the stop light switch.CAUTION:• Turn the stop light switch clockwise when installing so that it can return backward by approximately 1 mm (0.04 in) and clearance is automatically adjusted.• If it is hard to turn the switch, r ...