Subaru Crosstrek Service Manual: Brake line Inspection

PERIODIC MAINTENANCE SERVICES > Brake Line

INSPECTION

1. BRAKE LINE

1. Check for scratches, swelling, corrosion, traces of fluid leakage on the brake hoses or pipe joints.

2. Make sure that brake pipes/hoses do not interfere with adjacent parts and there is no loose connector/clamp during driving.

3. Check any trace of fluid leakage, scratches, etc. on master cylinder, wheel cylinder and hydraulic unit.

NOTE:

• When the brake fluid level in the reservoir tank is lower than specified limit, the brake warning light on the combination meter will illuminate.

• Visually check the brake hose for damage. (Use a mirror where it is difficult to see)

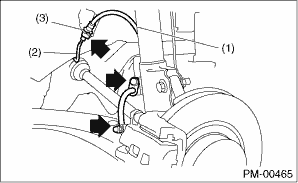

(1) | Front brake hose |

(2) | Front brake pipe |

(3) | Clamp |

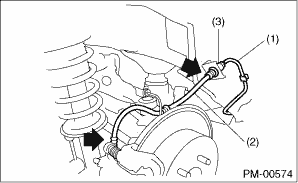

(1) | Brake pipe |

(2) | Rear brake hose |

(3) | Clamp |

2. SERVICE BRAKE

Refer to “BR” section for foot brake inspection. Brake Pedal > INSPECTION">

3. BRAKE SERVO SYSTEM

1. With the engine off, depress the brake pedal several times applying the same pedal force. Check that the travel distance should not change.

2. With the brake pedal depressed, start the engine. Check that the pedal moves slightly toward the floor.

3. With the brake pedal depressed, stop the engine and keep the pedal depressed for 30 seconds. Check that the pedal height does not change.

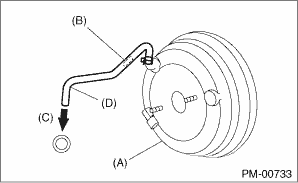

4. A check valve is built into the brake booster nipple. Disconnect the vacuum hose to inspect function of check valve.

Check that check valve ventilates from booster side to engine side. Also, check that there is no ventilation from engine side to booster side.

(A) | Brake booster |

(B) | Check valve |

(C) | Engine side |

(D) | Vacuum hose |

5. Check the vacuum hose for cracks or other damage.

CAUTION:

When installing the vacuum hose on the engine and brake booster, do not use soapy water or lubricating oil on their connections.

6. Check that the vacuum hose is securely tightened.

Axle boots joints Inspection

Axle boots joints Inspection

PERIODIC MAINTENANCE SERVICES > Axle Boots & JointsINSPECTION1. FRONT AND REAR AXLE BOOTSInspect the front axle boots (A) and rear axle boots (B) for deformation, damage or failure. If faulty, ...

Clutch system Inspection and adjustment

Clutch system Inspection and adjustment

PERIODIC MAINTENANCE SERVICES > Clutch SystemINSPECTION AND ADJUSTMENTRefer to “CL” section for inspection and adjustment of clutch system. Clutch Pedal > INSPECTION"> Clut ...

Other materials:

Check list for interview Check

POWER ASSISTED SYSTEM (POWER STEERING) (DIAGNOSTICS) > Check List for InterviewCHECKCheck the following items regarding condition of the vehicle.1. TROUBLE STATUSPhenomenon of the vehicle Steering is heavy Steering is not smooth Steering is unstable (wondering) Steering does not return to center ...

Dtc b2a04 mic circuit

TELEMATICS SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B2A04 MIC CIRCUITDiagnosis start condition:When ACC is ON.DTC detecting condition:Any of the followings continues for 1 second or more.• MIC impedance is more than 10 k?. (Detached MIC, etc.)• ...

Disassembly

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Transfer Driven GearDISASSEMBLY1. Using the ST, remove the taper roller bearing (extension case side).ST 498077000REMOVER(A)Taper roller bearing (extension case side)2. Using ST1 and ST2, remove the taper roller bearing (transfer case side).ST1 49 ...