Subaru Crosstrek Service Manual: Assembly

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Reverse Brake Assembly

ASSEMBLY

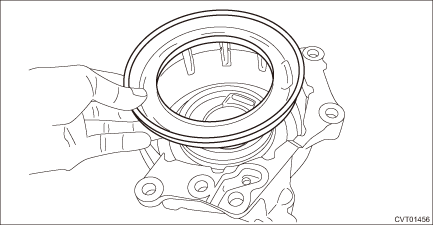

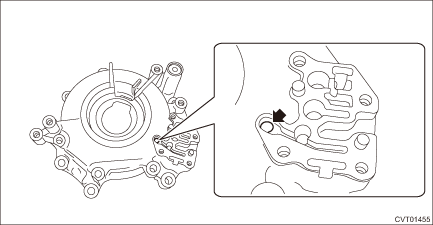

1. Install the reverse brake piston.

NOTE:

Apply CVTF to the sealing area of reverse brake piston.

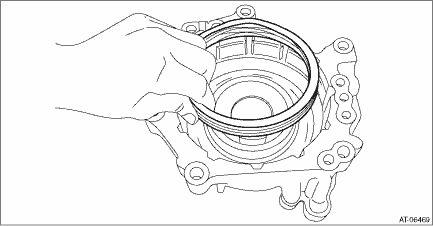

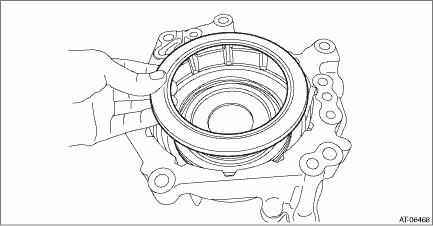

2. Install the return spring.

3. Install the spring retainer.

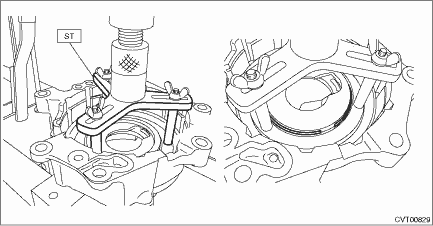

4. Compress the return spring using the ST to install the snap ring.

| ST1 18762AA001 | COMPRESSOR SPECIAL TOOL |

5. Check the operation of reverse brake piston by blowing compressed air intermittently from reverse brake housing hole.

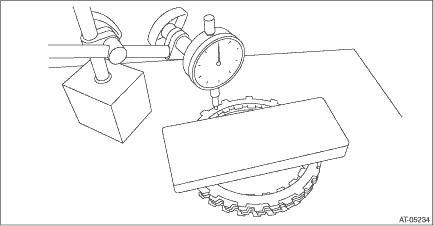

6. Place the driven plate, drive plate and retaining plate neatly in this order on surface table.

7. Set the dial gauge to retaining plate, and read its scale.

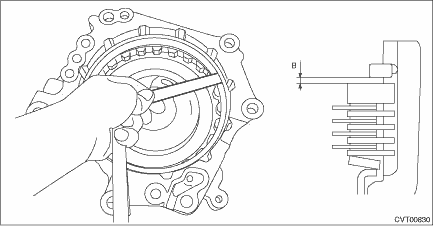

NOTE:

The value, which is read in the gauge at this time, is zero point.

8. Scale and record the weight “Z” of a flat board which will be put on retaining plate.

NOTE:

• Use a stiff board which does not bend against load as a flat board to be put on retaining plate.

• Use a flat board weighing less than 29 N (3.0 kgf, 6.5 lb).

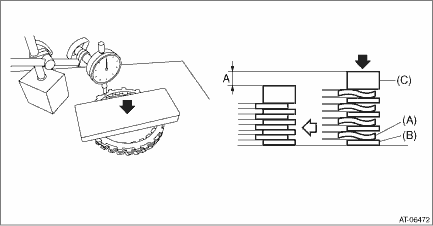

9. Put the flat board on retaining plate.

10. Using the following formula, read the push/pull gauge and calculate “N”.

N = 29 N (3.0 kgf, 6.5 lb) − Z

29 N (3.0 kgf, 6.5 lb): Load applied to clutch plate

Z: Flat board weight

11. Press the center of retaining plate by applying a force of “N” using push/pull gauge, and then measure and record the compression amount “A”.

NOTE:

Measure at four points with a 90° interval and calculate the average.

(A) | Drive plate |

(B) | Driven plate |

(C) | Retaining plate |

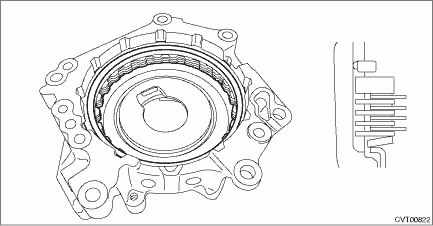

12. Install the dish plate, drive plate, driven plate, retaining plate and snap ring to the reverse brake housing.

NOTE:

Install the dish plate in the correct direction.

13. Measure and record the clearance “B” between the retaining plate and snap ring.

14. Piston stroke calculation

Calculate with A and B dimensions recorded before. If it exceeds the limit, replace with a new drive plate and adjust within the initial standard value.

S mm (in) = A + B

S: Piston stroke

A: Compression amount of drive plate and dish plate

B: Clearance between retaining plate and snap ring

Initial standard:

2.3 — 2.7 mm (0.091 — 0.106 in)

Limit thickness:

2.9 mm (0.114 in)

Retaining plate | |

Part No. | Thickness mm (in) |

31567AB750 | 4.2 (0.165) |

31567AB800 | 4.4 (0.173) |

31567AB810 | 4.6 (0.181) |

31567AB820 | 4.8 (0.189) |

Removal

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Reverse Brake AssemblyREMOVAL1. Remove the transmission assembly from the vehicle. Automatic Transmission Assembly > REMOVAL">2. Remove the a ...

Other materials:

Reclining the seatback

Pull the reclining lever up and adjust the

seatback to the desired position. Then

release the lever and make sure the

seatback is securely locked into place.

The seatback placed in a reclined position

can spring back upward with force when

the lever is pulled. While operating the

lever ...

General diagnostic table Inspection

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS) > General Diagnostic TableINSPECTIONSymptomsFaulty partsTire pressure warning light illuminates.Tire pressure is reduced.• Improper tire pressure adjustment• Punctured tireTire pressure warning light blinks 25 times and then illuminates.Ti ...

After driving

Always check your brakes for effectiveness

immediately after driving in sand,

mud or water. Do this by driving slowly

and stepping on the brake pedal. Repeat

that process several times to dry out the

brake discs and brake pads.

After driving through tall grass, mud,

rocks, sand, riv ...