Subaru Crosstrek Service Manual: Adjustment

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Drive Pinion Shaft Assembly

ADJUSTMENT

1. Remove the liquid gasket from the mating surface completely.

2. Using the ST, install the drive pinion retainer to converter case.

| ST 18270KA020 | SOCKET (E20) |

NOTE:

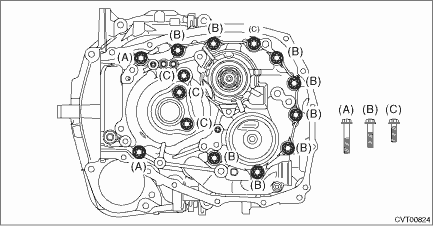

Do not confuse the three different-length bolts when installing.

Tightening torque:

43 N·m (4.4 kgf-m, 31.7 ft-lb)

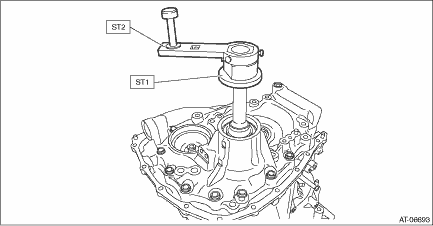

3. Rotate the drive pinion several times using ST1 and ST2.

| ST1 498937110 | HOLDER |

| ST2 499787700 | WRENCH |

4. Adjust the drive pinion and hypoid driven gear backlash. Front Differential Assembly > ADJUSTMENT">

5. Using the ST, remove the drive pinion retainer from converter case.

| ST 18270KA020 | SOCKET (E20) |

6. Apply lead-free red dye evenly on the both sides of three to four teeth of the hypoid driven gear. Then install the drive pinion retainer and rotate the drive pinion in both directions several times. Remove the drive pinion retainer and check the tooth contact pattern.

If the teeth contact is inappropriate, adjust the backlash or thickness of the shim. Front Differential Assembly > ADJUSTMENT">

NOTE:

After correction, wipe off the lead-free red dye.

Drive pinion shim | |

Part No. | Thickness mm (in) |

31451AA320 | 0.150 (0.0059) |

31451AA330 | 0.175 (0.0069) |

31451AA340 | 0.200 (0.0079) |

31451AA350 | 0.225 (0.0089) |

31451AA360 | 0.250 (0.0098) |

31451AA370 | 0.275 (0.0108) |

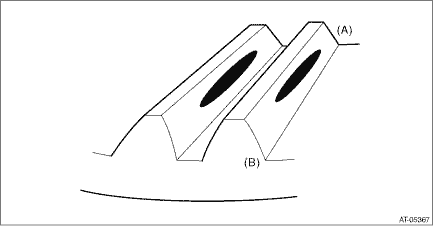

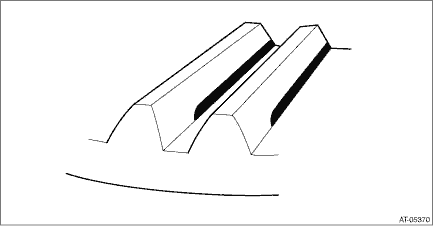

• Correct tooth contact

Check item: Tooth contact surface is slightly shifted toward the toe side under a no-load condition. (When driving, it moves towards the heel side.)

(A) | Toe side |

(B) | Heel side |

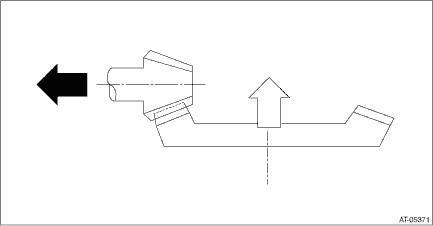

• Face contact

Check item: Backlash is too large.

Contact pattern

Corrective action: Increase thickness of drive pinion shim according to the procedures for moving the drive pinion close to hypoid driven gear.

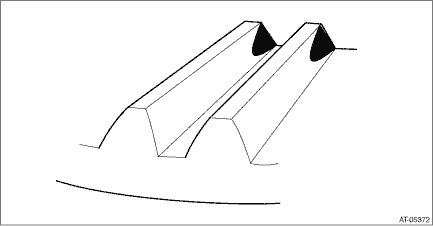

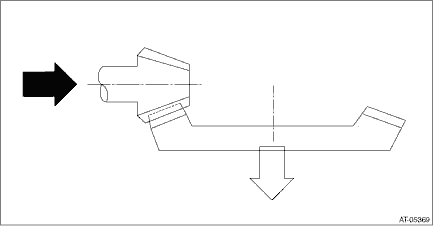

• Flank contact

Check item: Backlash is too small.

Contact pattern

Corrective action: Reduce the thickness of the drive pinion shim according to the procedures for moving the drive pinion away from the hypoid driven gear.

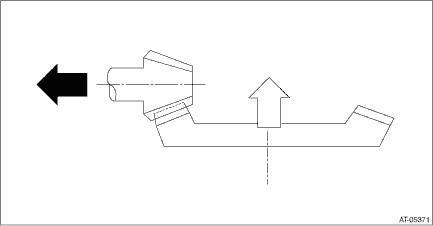

• Toe contact (inside contact)

Check item: Teeth contact area is too small.

Contact pattern

Corrective action: Reduce the thickness of the drive pinion shim according to the procedures for moving the drive pinion away from the hypoid driven gear side.

• Heel contact (outside end contact)

Check item: Teeth contact area is too small.

Contact pattern

Corrective action: Increase the thickness of the drive pinion shim according to the procedures for moving the drive pinion closer to the hypoid driven gear.

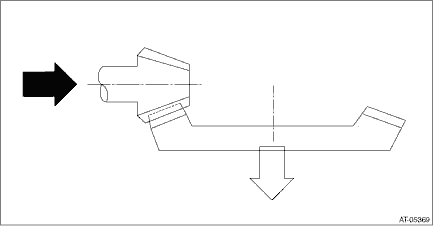

7. Using the ST, loosen the differential side retainer until the mounting groove of the O-ring appears, and then install the O-ring.

NOTE:

• When loosening the differential side retainer, record the number of the turns made.

• Perform this for both left and right differential side retainers.

• Use new O-rings.

• Apply the differential gear oil to O-ring.

| ST 18658AA020 | WRENCH COMPL RETAINER |

8. Using the ST, tighten the retainer to the position before it is loosened.

| ST 18658AA020 | WRENCH COMPL RETAINER |

9. Replace the differential side retainer oil seal with a new part. Differential Side Retainer Oil Seal">

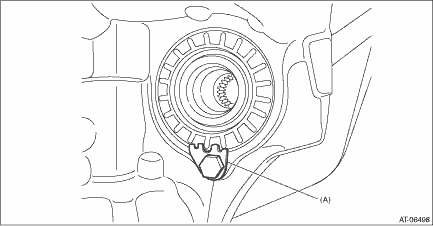

10. Install the lock plate.

Tightening torque:

25 N·m (2.5 kgf-m, 18.4 ft-lb)

(A) | Lock plate |

Removal

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Drive Pinion Shaft AssemblyREMOVAL1. Remove the transmission assembly from the vehicle. Automatic Transmission Assembly > REMOVAL">2. Remove ...

Other materials:

Dtc p2746 intermediate shaft speed sensor "b" circuit range/performance

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2746 INTERMEDIATE SHAFT SPEED SENSOR "B" CIRCUIT RANGE/PERFORMANCEDTC detecting condition:Immediately at fault recognitionTrouble symptom:• Standing start problems• ...

Installation

LIGHTING SYSTEM > Combination Switch (Light)INSTALLATIONCAUTION:• Before handling the airbag system components, refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">• Do not allow harness and con ...

Dtc b1815 short in passenger s airbag dual stage - 2nd step

AIRBAG SYSTEM (DIAGNOSTICS) > Diagnostic Chart with Trouble CodeDTC B1815 SHORT IN PASSENGER’S AIRBAG DUAL STAGE - 2ND STEPDiagnosis start condition:Ignition voltage is 10 V to 16 V.DTC detecting condition:• Airbag main harness circuit is shorted.• Airbag module harness circuit ...