Subaru Crosstrek Service Manual: Adjustment

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Primary Pulley and Secondary Pulley

ADJUSTMENT

1. PROCEDURE IN REPLACEMENT OF PRIMARY AND SECONDARY PULLEY, OR IN REPLACEMENT OF PRIMARY PULLEY, SECONDARY PULLEY AND VARIATOR CHAIN

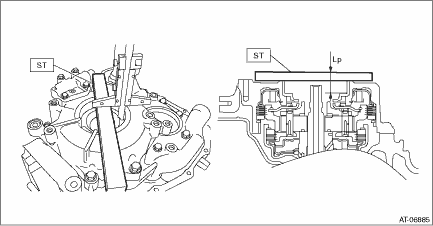

1. Measure depth “Lp” from the ST upper face to the primary pulley bearing catch surface at several points and calculate the average.

| ST 499575400 | GAUGE |

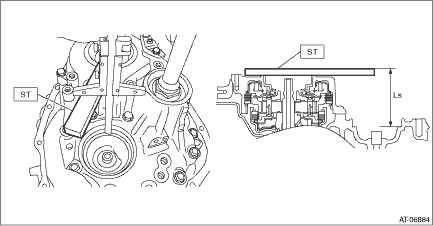

2. Measure the depth “Ls” from the ST upper face to the secondary pulley bearing catch surface at several points and calculate the average.

| ST 499575400 | GAUGE |

3. Calculate the following formula.

Calculation formula:

T (mm) = B − A + Lp − Ls − 28.602

[T (in) = B − A + Lp − Ls − 1.126]

T: Pulley alignment

A: Specified primary pulley dimension

B: Specified secondary pulley dimension

Lp: Depth from the ST upper face to the primary pulley bearing catch surface

Ls: Depth from the ST upper face to the secondary pulley bearing catch surface

28.602 mm (1.126 in): Constant

Pulley alignment T mm (in) | Thickness of shim mm (in) |

−0.05 — 0.049 (−0.002 — 0.002) | No shims |

0.050 — 0.149 (0.002 — 0.006) | 0.1 (0.004) |

0.150 — 0.249 (0.006 — 0.010) | 0.2 (0.008) |

0.250 — 0.349 (0.010 — 0.014) | 0.3 (0.012) |

0.350 — 0.449 (0.014 — 0.018) | 0.4 (0.016) |

0.450 — 0.549 (0.018 — 0.022) | 0.5 (0.020) |

0.550 — 0.649 (0.022 — 0.026) | 0.6 (0.024) |

0.650 — 0.749 (0.026 — 0.029) | 0.7 (0.028) |

0.750 — 0.849 (0.029 — 0.033) | 0.8 (0.031) |

0.850 — 0.949 (0.033 — 0.037) | 0.9 (0.035) |

0.950 — 1.049 (0.037 — 0.041) | 1.0 (0.039) |

1.050 — 1.149 (0.041 — 0.045) | 1.1 (0.043) |

4. Select one to two shims so that the total thickness meets the value obtained from step 3).

Part No. | Shim thickness mm (in) |

32451AA050 | 0.1 (0.004) |

32451AA060 | 0.2 (0.008) |

32451AA070 | 0.3 (0.012) |

32451AA080 | 0.4 (0.016) |

32451AA090 | 0.5 (0.020) |

32451AA100 | 0.6 (0.024) |

2. PROCEDURE WHEN REPLACING ONLY DRIVE PINION RETAINER OR REVERSE BRAKE HOUSING

1. Clean the mating surface of current drive pinion retainer and converter case.

2. Measure and record the shim thickness that is attached on the current reverse brake housing.

3. Using the current drive pinion retainer, measure depth “Lp1” from the ST upper face to the primary pulley bearing catch surface at several points and calculate the average.

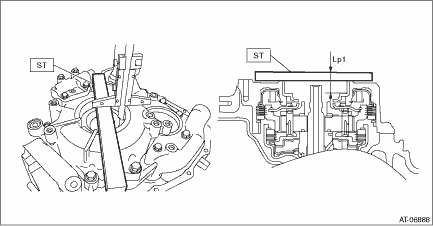

| ST 499575400 | GAUGE |

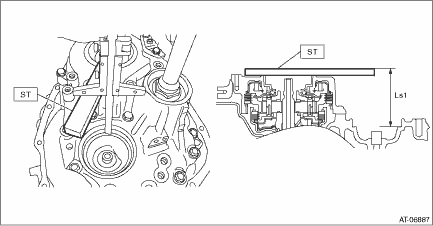

4. Using the current drive pinion retainer or current reverse brake housing, measure the depth “Ls1” from the ST upper face to the secondary pulley bearing catch surface at several points and calculate the average.

| ST 499575400 | GAUGE |

5. Calculate the “LD1” using the following formula and record it.

Calculation formula:

LD1 mm (in) = Ls1 − Lp1

LD1: Height from the primary pulley bearing catch surface to the secondary pulley bearing catch surface

Lp1: Depth from the ST upper face to the primary pulley bearing catch surface

Ls1: Depth from the ST upper face to the secondary pulley bearing catch surface

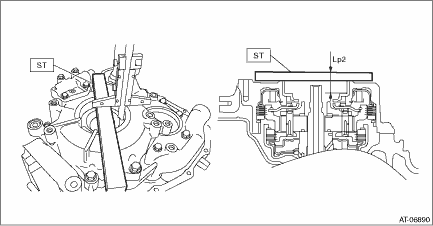

6. Using the new drive pinion retainer or new reverse brake housing, measure the depth “Lp2” from the ST upper face to the primary pulley bearing catch surface at several points and calculate the average.

| ST 499575400 | GAUGE |

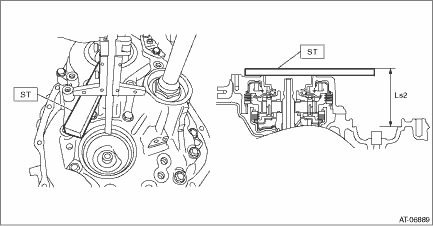

7. Using the new drive pinion retainer or new reverse brake housing, measure the depth “Ls2” from the ST upper face to the secondary pulley bearing catch surface at several points and calculate the average.

| ST 499575400 | GAUGE |

8. Calculate the “LD2” using the following formula and record it.

Calculation formula:

LD2 mm (in) = Ls2 − Lp2

LD2: Height from the primary pulley bearing catch surface to the secondary pulley bearing catch surface

Lp2: Depth from the ST upper face to the primary pulley bearing catch surface

Ls2: Depth from the ST upper face to the secondary pulley bearing catch surface

9. Calculate the recorded values of “LD1” and “LD2” to obtain the positive number to select the shims.

Calculation formula: T1 mm (in) = LD1 − LD2 or T2 mm (in) = LD2 − LD1

T1, T2: Difference between new drive pinion retainer or new reverse brake housing and current drive pinion retainer or current reverse brake housing

LD1: Calculated value of current drive pinion retainer or current reverse brake housing

LD2: Calculated value of new drive pinion retainer or new reverse brake housing

Difference of the case (T1) mm (in) | Shim selection procedure |

0 — 0.050 (0 — 0.00197) | Select a new shim of the same thickness with the shim that is used on the primary pulley side of the current reverse brake housing. |

0.051 — 0.150 (0.00201 — 0.00591) | Select a shim which is 0.1 mm (0.004 in) thicker than the shim that is used on the primary pulley side of the current reverse brake housing. |

0.151 — 0.250 (0.00594 — 0.00984) | Select a shim which is 0.2 mm (0.008 in) thicker than the shim that is used on the primary pulley side of the current reverse brake housing. |

0.251 — 0.350 (0.00988 — 0.01378) | Select a shim which is 0.3 mm (0.012 in) thicker than the shim that is used on the primary pulley side of the current reverse brake housing. |

0.351 — 0.450 (0.01382 — 0.01772) | Select a shim which is 0.4 mm (0.016 in) thicker than the shim that is used on the primary pulley side of the current reverse brake housing. |

0.451 — 0.550 (0.01776 — 0.02165) | Select a shim which is 0.5 mm (0.020 in) thicker than the shim that is used on the primary pulley side of the current reverse brake housing. |

0.551 — 0.600 (0.02169 — 0.02362) | Select a shim which is 0.6 mm (0.024 in) thicker than the shim that is used on the primary pulley side of the current reverse brake housing. |

Difference of the case (T2) mm (in) | Shim selection procedure |

0 — 0.050 (0 — 0.00197) | Select a new shim of the same thickness with the shim that is used on the primary pulley side of the current reverse brake housing. |

0.051 — 0.150 (0.00201 — 0.00591) | Select a shim which is 0.1 mm (0.004 in) thinner than the shim that is used on the primary pulley side of the current reverse brake housing. |

0.151 — 0.250 (0.00594 — 0.00984) | Select a shim which is 0.2 mm (0.008 in) thinner than the shim that is used on the primary pulley side of the current reverse brake housing. |

0.251 — 0.350 (0.00988 — 0.01378) | Select a shim which is 0.3 mm (0.012 in) thinner than the shim that is used on the primary pulley side of the current reverse brake housing. |

0.351 — 0.450 (0.01382 — 0.01772) | Select a shim which is 0.4 mm (0.016 in) thinner than the shim that is used on the primary pulley side of the current reverse brake housing. |

0.451 — 0.550 (0.01776 — 0.02165) | Select a shim which is 0.5 mm (0.020 in) thinner than the shim that is used on the primary pulley side of the current reverse brake housing. |

0.551 — 0.600 (0.02169 — 0.02362) | Select a shim which is 0.6 mm (0.024 in) thinner than the shim that is used on the primary pulley side of the current reverse brake housing. |

Part No. | Shim thickness mm (in) |

32451AA050 | 0.1 (0.004) |

32451AA060 | 0.2 (0.008) |

32451AA070 | 0.3 (0.012) |

32451AA080 | 0.4 (0.016) |

32451AA090 | 0.5 (0.020) |

32451AA100 | 0.6 (0.024) |

Removal

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Primary Pulley and Secondary PulleyREMOVALNOTE:Always replace primary pulley and secondary pulley as an assembly because they are non-disassembled parts. ...

Other materials:

OFF delay timer

The following lights have an automatic

illumination function.

dome light

map light (type A)

cargo area light

After being illuminated automatically,

these lights remain on for several seconds

and then gradually turn off under the

following conditions

after all doors are closed (type A ...

Compression Inspection

MECHANICAL(H4DO) > CompressionINSPECTIONCAUTION:After warming-up, engine becomes very hot. Be careful not to burn yourself during measurement.1. Turn the ignition switch to OFF.2. After warming-up the engine, turn the ignition switch to OFF.3. Make sure that the battery is fully charged.4. Check ...

Adjustment

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > CVTFADJUSTMENTCAUTION:• CVTF level changes along with CVTF temperature. When inspecting CVTF level, observe the specified CVTF temperature.• Always use specified CVTF. Using other fluid will cause malfunction.1. Idle the engine to raise CVTF ...