Subaru Crosstrek Service Manual: Removal

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Fuel Filter

REMOVAL

WARNING:

Place “NO OPEN FLAMES” signs near the working area.

CAUTION:

• Be careful not to spill fuel.

• If the fuel gauge indicates that two thirds or more of the fuel is remaining, be sure to drain fuel before starting work to avoid the fuel to spill.

• Be careful not to drop or apply any impact to the fuel pump during work. This may deteriorate its performance.

NOTE:

The fuel filter is built in fuel pump assembly.

1. Remove the fuel pump assembly. Fuel Pump > REMOVAL">

2. Remove the fuel level sensor. Fuel Level Sensor > REMOVAL">

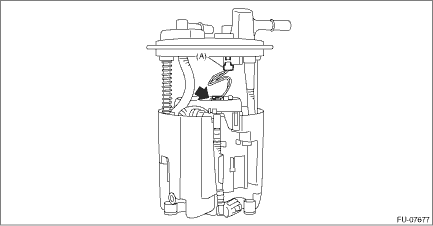

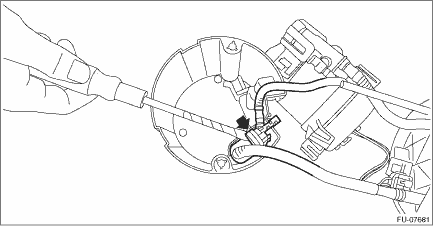

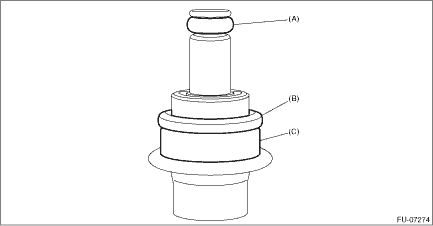

3. Remove the connector cable from the clip, and disconnect the connector (A) of the connector cable.

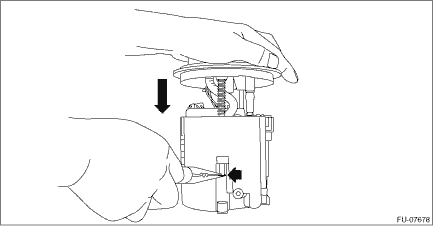

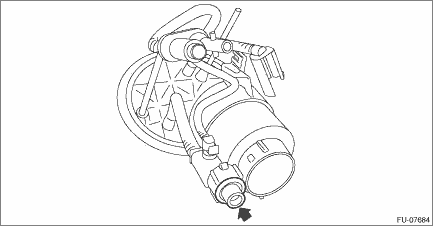

4. Push the fuel filter assembly in the direction of the arrow to compress, and detach the connecting clip.

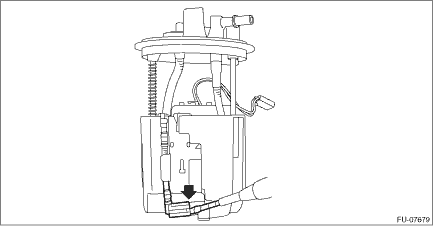

5. Release the claw using a flat tip screwdriver or similar tool wrapped with a protection tape, and remove the tube assembly from the fuel chamber assembly.

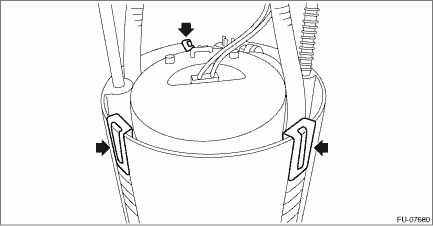

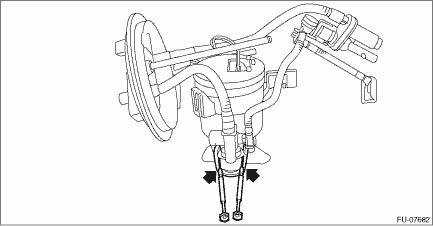

6. Release three claws on the fuel pump holder from the fuel chamber assembly, and raise the fuel filter assembly.

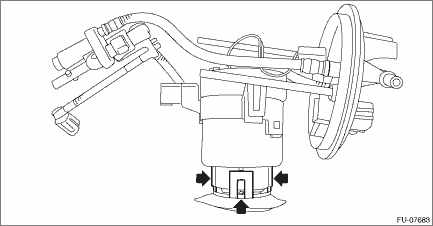

7. Using a flat tip screwdriver or similar tool wrapped with a protection tape, remove the tube assembly from the fuel chamber assembly, and separate the fuel filter assembly and fuel chamber assembly.

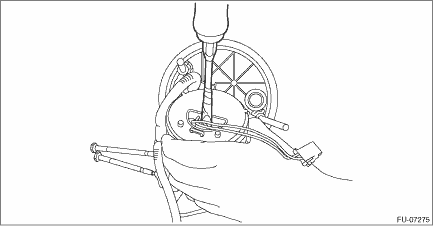

8. Using a precision driver or similar tool wrapped with a protection tape, expand the claws on the fuel pump.

9. Release the claws on the fuel pump.

10. Using a flat tip screwdriver or similar tool wrapped with a protection tape, press on the fuel pump and remove the fuel pump together with the fuel pump holder from the fuel filter assembly.

CAUTION:

If O-rings remain on the fuel filter assembly side, carefully remove them with a precision screwdriver or similar tool wrapped with a protection tape.

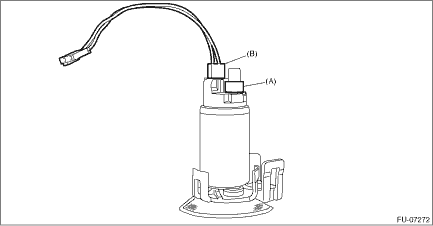

11. Remove the spacer (A) and connector cable (B) from the fuel pump.

12. Remove the pressure regulator from the fuel filter assembly.

13. Remove O-ring (A), O-ring (B), and backup ring (C) from the pressure regulator.

Installation

Installation

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Fuel FilterINSTALLATION1. Install O-ring (A), O-ring (B), and backup ring (C) to the pressure regulator.NOTE:• Use new O-rings.• Apply gasoline to ...

Fuel injector

Fuel injector

...

Other materials:

Dtc c0051 valve relay

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C0051 VALVE RELAYDTC detecting condition:Defective valve relayTrouble symptom:• ABS does not operate.• EBD does not operate.• VDC does not operate.• EyeSight does not ...

Fog light switch

Headlight switch

Fog light switch

The front fog lights will turn on when the

fog light switch is placed in the "

"

position while the headlights are in the

following condition.

while the headlight switch is in the "

"

position

for models with the auto on/off h ...

How to read wiring diagrams

WIRING SYSTEM > Basic Diagnostic ProcedureHOW TO READ WIRING DIAGRAMS1. WIRING DIAGRAMThe wiring diagram of each system is illustrated so that you can understand the path through which the electric current flows from the battery.Sketches and codes are used in the diagrams. They should read as fol ...