Subaru Crosstrek Service Manual: Installation

WIPER AND WASHER SYSTEMS > Front Wiper Motor and Link

INSTALLATION

CAUTION:

• If the cowl panel assembly cannot be installed properly, do not hit or set it forcibly. The claws of the cowl panel or the windshield glass may be damaged.

• Before installing the windshield glass and cowl panel, make sure there are no gravel in the installing area.

1. Connect the battery ground terminal. NOTE">

2. To confirm that the motor assembly - windshield wiper is at the auto stop position, connect the harness to the motor and turn the wiper switch to ON/OFF once.

CAUTION:

During motor operation, do not touch the movable part.

3. Disconnect the ground cable from battery again. NOTE">

4. Install the motor assembly - windshield wiper.

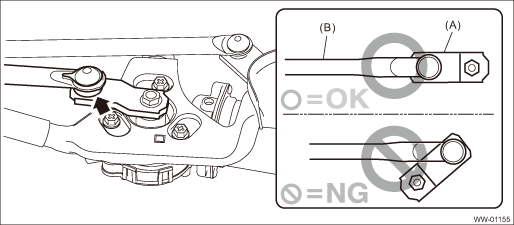

(1) Align the link plate position.

CAUTION:

Install the motor assembly - windshield wiper at the position where the rod (B) and link plate (A) are aligned in a straight line.

(2) Install the motor assembly - windshield wiper.

Tightening torque:

5.5 N·m (0.56 kgf-m, 4.1 ft-lb)

5. Install the cowl panel - side and the cowl panel assembly. Cowl Panel > INSTALLATION">

6. Install the arm assembly - windshield wiper. Front Wiper Arm > INSTALLATION">

7. Connect the battery ground terminal. NOTE">

8. Operate the windshield wiper to check that the stop position is aligned with the point mark.

If it is not aligned with the point mark, perform the removal and installation of the windshield wiper over again. Front Wiper Arm > REMOVAL">

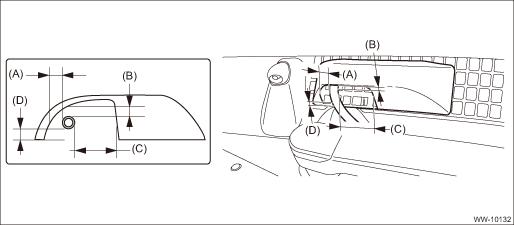

9. Make sure that there is a gap of 1 mm (0.04 in) or more between the hose and the cover joint and between the hose and the joint washer hose during windshield wiper operation. (Models with EyeSight)

(A) | Gap between hose and cover joint outer side | (C) | Gap between hose and cover joint inner side | (D) | Gap between hose and cover joint lower side |

(B) | Gap between hose and cover joint upper side |

Removal

Removal

WIPER AND WASHER SYSTEMS > Front Wiper Motor and LinkREMOVAL1. Disconnect the ground cable from battery. NOTE">2. Remove the arm assembly - windshield wiper. Front Wiper Arm > REMOVAL& ...

Other materials:

Passenger s airbag on/off indicator light illumination pattern Inspection

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS) > Passenger’s Airbag ON/OFF Indicator Light Illumination PatternINSPECTION(1)Passenger’s airbag ON indicator light(6)Light ON(10)OFF(2)Passenger’s airbag OFF indicator light(7)Empty(11)ON(3)Occupant seating(8)Child(12)Approx. 6 sec.(4)Igni ...

Assembly

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Center DifferentialASSEMBLYInstall the ball bearings.CAUTION:Do not apply a load in excess of 10 kN (1 ton, 1.1 US ton, 1.0 Imp ton).NOTE:Use a new ball bearing.(A)Ball bearing ...

Installation

ENTERTAINMENT > Front Accessory Power Supply SocketINSTALLATIONCAUTION:• After installing the center grille assembly, check that the air vent grille of the center grille assembly is inserted correctly into the air vent duct.• Before handling the airbag system components, always refer ...