Subaru Crosstrek Service Manual: Installation

WHEEL AND TIRE SYSTEM > Tire Pressure Monitoring System

INSTALLATION

1. TRANSMITTER (TIRE INFLATION PRESSURE SENSOR)

CAUTION:

Use the new transmitter assembly or replace the new valve and screw, when installing.

1. Replace the valve and screw with a new part when reusing transmitter.

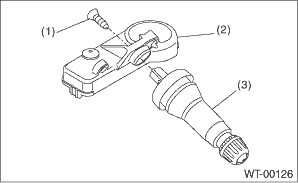

(1) | Screw |

(2) | Transmitter |

(3) | Valve |

Tightening torque:

1.4 N·m (0.14 kgf-m, 1.0 ft-lb)

2. Install the transmitter to the wheel by aligning it with valve hole.

NOTE:

When using the jig that pulls the valve cap by hooking its neck part, use another short-type cap.

3. Install the tires to wheels.

CAUTION:

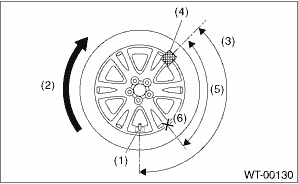

• Use a tire changer when installing tire to wheel.

• To prevent damaging the transmitter, set the tire changer boom in the position as shown in the figure.

(1) | Transmitter |

(2) | Direction of turn table rotation |

(3) | 135° |

(4) | Tire changer boom |

(5) | 90° |

(6) | Starting point for fitting the bead to the rim |

4. Install the wheels to vehicle. Tire and Wheel > INSTALLATION">

5. Register the transmitter ID to the TPMS & keyless control module. Register Transmitter (ID)">

2. TPMS & KEYLESS CONTROL MODULE

Install each part in the reverse order of removal.

Tightening torque:

13 N·m (1.33 kgf-m, 9.6 ft-lb)

3. TPMS CM

Install each part in the reverse order of removal.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

Removal

Removal

WHEEL AND TIRE SYSTEM > Tire Pressure Monitoring SystemREMOVAL1. TRANSMITTER (TIRE INFLATION PRESSURE SENSOR)1. Remove the wheels from the vehicle. Tire and Wheel > REMOVAL">2. Remove t ...

General diagnostic table Inspection

General diagnostic table Inspection

WHEEL AND TIRE SYSTEM > General Diagnostic TableINSPECTIONSymptomsPossible causeCorrective actionWheel is out of balance.Improperly inflated tire.Adjust the tire pressure.Uneven wearCheck the tire ...

Other materials:

Component

SUNROOF/T-TOP/CONVERTIBLE TOP (SUNROOF) > General DescriptionCOMPONENT(1)Lid ASSY - sunroof(6)Deflector ASSY - sunroofTightening torque: N·m (kgf-m, ft-lb)(2)Weather strip(7)Rail ASSY - sunroofT1:4.5 (0.46, 3.3)(3)Sunshade ASSY(8)Link - drain sunroofT2:6 (0.61, 4.4)(4)Drain tube - sunroof( ...

Wiring diagram

SECURITY AND LOCKS > Keyless Access SystemWIRING DIAGRAMFor wiring diagrams related to the keyless access system, refer to the following items.• Keyless access system: Keyless Access System > WIRING DIAGRAM">• Push button start system: Push Button Start System > WIRING ...

Vehicle dynamics control system Wiring diagram

WIRING SYSTEM > Vehicle Dynamics Control SystemWIRING DIAGRAM1. WITHOUT EyeSight2. WITH EyeSight ...