Subaru Crosstrek Service Manual: Installation

FRONT SUSPENSION > Front Crossmember

INSTALLATION

1. Check the crossmember for damage or cracks, and correct or replace if defective.

2. Install the universal joint assembly - steering. Universal Joint > INSTALLATION">

3. Install each part in the reverse order of removal.

CAUTION:

• Use a new bolt and self-locking nut. For parts which are not reusable, refer to “COMPONENT”. General Description > COMPONENT">

• Always tighten the bushing in the state where the vehicle is at curb weight and the wheels are in full contact with the ground.

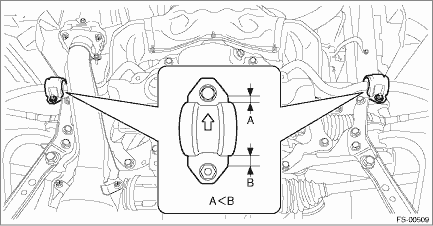

• Install the clamp - stabilizer bushing with the arrow mark facing the front of the vehicle.

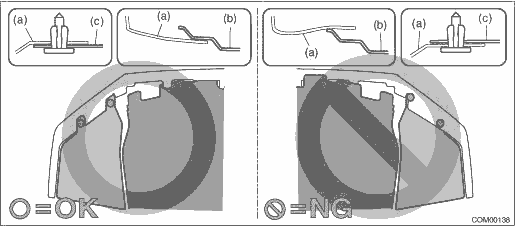

• Install so that the front end of the under cover (b) comes inside the bumper face - front (a), and the front end of the mud guard (c) comes outside the bumper face - front (a).

Tightening torque:

Engine mounting to Front crossmember assembly: General Description > COMPONENT">

Universal joint assembly - steering: 24 N·m (2.45 kgf-m, 17.7 ft-lb)

V-belt cover: 7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

Under cover - front: 18 N·m (1.84 kgf-m, 13.3 ft-lb)

Front suspension parts: General Description > COMPONENT">

When tightening the castle nut, tighten the castle nut to the specified torque first, then tighten it further but within 60° until the hole in the ball stud is aligned with a slot in castle nut.

4. Install the front wheels.

Tightening torque:

Except for C4 model: 120 N·m (12.24 kgf-m, 88.5 ft-lb)

C4 model: 100 N·m (10.20 kgf-m, 73.8 ft-lb)

5. Inspect the wheel alignment and adjust if necessary.

• Inspection: Wheel Alignment > INSPECTION">

• Adjustment: Wheel Alignment > ADJUSTMENT">

CAUTION:

If the steering wheel and steering angle sensor are removed, perform the following VDC setting mode.

– Model without EyeSight: VDC sensor midpoint setting mode VDC Control Module and Hydraulic Control Unit (VDCCM&H/U) > ADJUSTMENT">

– Model with EyeSight: Neutral of Steering Angle Sensor & Lateral G Sensor 0 point setting VDC Control Module and Hydraulic Control Unit (VDCCM&H/U) > ADJUSTMENT">

– Model with EyeSight: Longitudinal G sensor & lateral G sensor 0 point setting VDC Control Module and Hydraulic Control Unit (VDCCM&H/U) > ADJUSTMENT">

6. Perform reinitialization of the auto headlight beam leveler system. (Model with auto headlight beam leveler) Auto Headlight Beam Leveler System > PROCEDURE">

Removal

Removal

FRONT SUSPENSION > Front CrossmemberREMOVALCAUTION:• The power steering control module continues to operate after the engine stops and calculate the temperature in the control module. Therefo ...

Other materials:

Dtc u0422 invalid data received from body control module

Blind Spot Detection/Rear Cross Traffic Alert (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC U0422 INVALID DATA RECEIVED FROM BODY CONTROL MODULEReceived error data from BIU.NOTE:Perform the diagnosis for LAN system. Basic Diagnostic Procedure > PROCEDURE"> ...

Installation

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Front Differential AssemblyINSTALLATION1. Install the front differential assembly to the converter case.NOTE:Be careful not to damage the inside of the case (especially the mounting surface of the differential side retainers).2. Install the bearing oute ...

Dtc c2512 torque sensor sub

POWER ASSISTED SYSTEM (POWER STEERING) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C2512 TORQUE SENSOR SUBNOTE:Refer to “DTC C2511 TORQUE SENSOR MAIN” for diagnostic procedure. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC C2511 TORQU ...