Subaru Crosstrek Service Manual: Inspection

AIRBAG SYSTEM > Roll Connector

INSPECTION

1. VISUAL INSPECTION

Check for the following, and replace the damaged parts with new parts.

• Combination switch is cracked or deformed.

• Roll connector is cracked or deformed.

2. UNIT INSPECTION OF ROLL CONNECTOR

CAUTION:

• Do not rotate the roll connector to more than the specified number of turns. Otherwise, the roll connector internal wire may be broken.

• When determining the end stop, rotate the connector slowly without applying excessive force. Applying excessive force at the end stop may break the internal wire.

1. Adjust the roll connector. Roll Connector > ADJUSTMENT">

2. Set the roll connector to the central position.

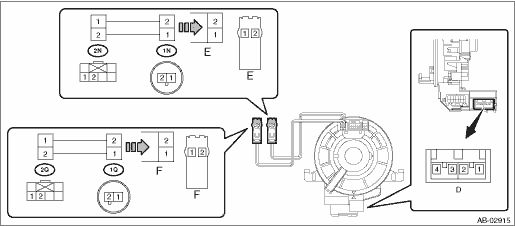

3. Connect the test harness to the connector E and connector F.

Preparation tool:

Test harness N (98299SA000)

Test harness Q (98299SA040)

• Connector E - Test harness N (1N)

• Connector F - Test harness Q (1Q)

4. With the following conditions, check the resistance between the test harness connector terminals.

• Perform the check with the roll connector centered (front wheels direct straightforward).

• Rotate the roll connector counterclockwise from the center (front wheels direct straightforward) to an end stop. Then, perform the check while rotating it clockwise to approximately 4.5 turns.

Preparation tool:

Circuit tester

Terminal No. | Inspection conditions | Standard |

(2N) No. 1 — (2N) No. 2 | Always | Less than 1 ? |

(2Q) No. 1 — (2Q) No. 2 | Always | Less than 1 ? |

NOTE:

The connector D is designed to short the terminals D1/D2 and D3/D4 when disconnected.

5. Replace the roll connector with a new part if the inspection result is not within the standard value.

Removal

Removal

AIRBAG SYSTEM > Roll ConnectorREMOVALCAUTION:Before handling the airbag system components, refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. Gener ...

Installation

Installation

AIRBAG SYSTEM > Roll ConnectorINSTALLATIONCAUTION:If the steering wheel and steering angle sensor (steering roll connector) are removed, be sure to perform the following operations.• Align th ...

Other materials:

Inspection

LIGHTING SYSTEM > Luggage Room LightINSPECTION1. LUGGAGE ROOM LIGHT BULB1. Visually check the bulb for blow out.2. Check the bulb specification. General Description > SPECIFICATION">3. Replace the bulb if it is found defective.2. LUGGAGE ROOM LIGHT SWITCH1. Check the resistance betwee ...

Inspection

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Tumble Generator Valve AssemblyINSPECTION1. CHECK MOTOR1. Connect the battery positive terminal to terminal No. 5 and the battery ground terminal to terminal No. 4, and check that the valve is fully opened on LH side and the valve is fully closed on RH side.C ...

Preparation tool

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > General DescriptionPREPARATION TOOL1. GENERAL TOOLTOOL NAMEREMARKSCircuit testerUsed for measuring resistance, voltage and current. ...