Subaru Crosstrek Service Manual: Inspection

BRAKE > Rear Disc Rotor

INSPECTION

1. DISC ROTOR RUNOUT CHECK

1. Check the hub unit COMPL - rear axle for free play and runout before the inspection of disc rotor runout limit. Rear Hub Unit Bearing > INSPECTION">

2. Check the disc rotor runout.

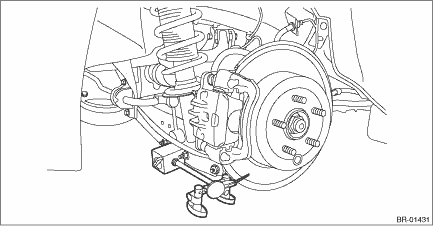

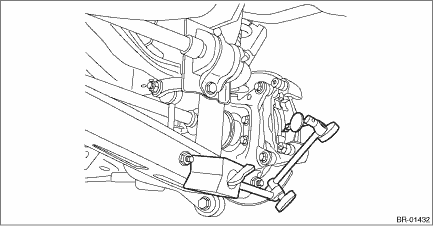

(1) Remove the caliper body assembly. Rear Disc Brake Assembly > REMOVAL">

(2) Secure the disc rotor by tightening the five wheel nuts.

(3) Set a dial gauge 10 mm (0.39 in) inward from the disc rotor outer circumference, and check the outer disc rotor runout while rotating the disc rotor.

Disc rotor runout limit:

0.05 mm (0.0020 in)

(4) Set a dial gauge 10 mm (0.39 in) inward from the disc rotor outer circumference, and check the inner disc rotor runout while rotating the disc rotor.

Disc rotor runout limit:

0.05 mm (0.0020 in)

3. If the disc rotor runout exceeds service limit, resurface the disc rotor.

4. Check the disc rotor thickness after resurfacing. Rear Disc Rotor > INSPECTION">

2. DISC ROTOR THICKNESS CHECK

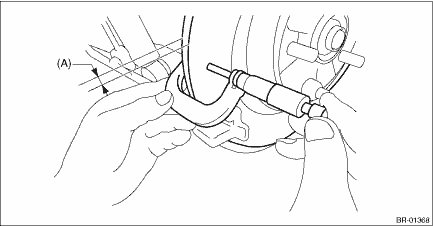

1. Set a micrometer 10 mm (0.39 in) inward from the disc rotor outer perimeter, and then measure the disc rotor thickness (A).

Type of disc rotor | Standard | Wear limit | Disc rotor outer diameter | |

Disc rotor thickness (A) | Solid disc | 10 mm (0.39 in) | 8.5 mm (0.33 in) | 274 mm (10.79 in) |

2. If the wear limit is exceeded in the inspection, replace the disc rotor.

Rear disc rotor

Rear disc rotor

...

Removal

Removal

BRAKE > Rear Disc RotorREMOVAL1. Lift up the vehicle, and then remove the rear wheels.2. Release the lever assembly - hand brake.3. Remove the caliper body assembly from the housing assembly - rear ...

Other materials:

Inspection

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Reverse Brake AssemblyINSPECTION• Inspect the drive plate facing for wear and damage.• Check the driven plate for discoloration (burnt color).• Check for worn snap ring, fatigue or damaged return spring or deformed spring retainer.&bul ...

Driving with a trailer

You should allow for considerably more

stopping distance when towing a trailer.

Avoid sudden braking because it may

result in skidding or jackknifing and loss of

control.

Avoid abrupt starts and sudden accelerations.

If your vehicle has a manual

transmission, always start out in ...

List

AIRBAG SYSTEM (DIAGNOSTICS) > Read Current DataLISTItemDisplayNoteTrip Count — — Count — — Time Count [msec] — — Belt Buckle Switch RHUnbelted/Belted“Belted” when passenger’s seat belt is fastened“Unbelted” when passenger’s seat belt is not faste ...