Subaru Crosstrek Service Manual: Fuel injector circuit

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostics for Engine Starting Failure

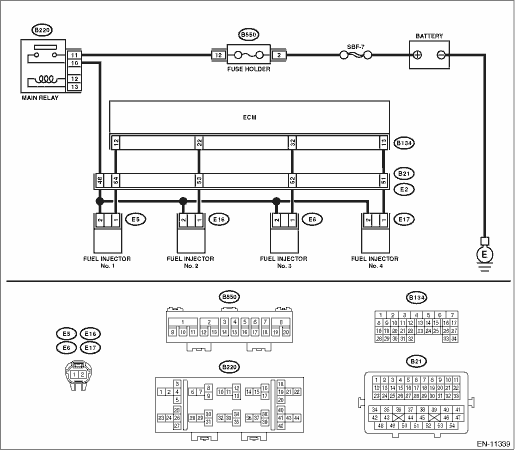

FUEL INJECTOR CIRCUIT

CAUTION:

• Check or repair only faulty parts.

• After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

WIRING DIAGRAM:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK OPERATION OF EACH FUEL INJECTOR.

While cranking the engine, check each fuel injector emits operating sound. Use a sound scope or attach a screwdriver to the injector to listen to sounds for this check.

Does the fuel injector emit operating sound?

Check the fuel pressure. Fuel Pressure > INSPECTION">

Diagnostics for Engine Starting Failure > FUEL INJECTOR CIRCUIT">Go to Step 2.

2.CHECK POWER SUPPLY TO EACH FUEL INJECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel injector.

3) Turn the ignition switch to ON.

4) Measure the power supply voltage between fuel injector terminal and engine ground.

Connector & terminal

#1 (E5) No. 2 (+) — Engine ground (−):

#2 (E16) No. 2 (+) — Engine ground (−):

#3 (E6) No. 2 (+) — Engine ground (−):

#4 (E17) No. 2 (+) — Engine ground (−):

Is the voltage 10 V or more?

Diagnostics for Engine Starting Failure > FUEL INJECTOR CIRCUIT">Go to Step 3.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit in harness between main relay connector and fuel injector connector

• Poor contact of main relay connector

• Poor contact of coupling connector

3.CHECK HARNESS BETWEEN ECM AND FUEL INJECTOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Measure the resistance of harness between ECM connector and fuel injector connector.

Connector & terminal

#1 (B134) No. 12 — (E5) No. 1:

#2 (B134) No. 22 — (E16) No. 1:

#3 (B134) No. 32 — (E6) No. 1:

#4 (B134) No. 13 — (E17) No. 1:

Is the resistance less than 1 ??

Diagnostics for Engine Starting Failure > FUEL INJECTOR CIRCUIT">Go to Step 4.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit in harness between ECM connector and fuel injector connector

• Poor contact of coupling connector

4.CHECK HARNESS BETWEEN ECM AND FUEL INJECTOR CONNECTOR.

Measure the resistance between ECM connector and chassis ground.

Connector & terminal

#1 (B134) No. 12 — Chassis ground:

#2 (B134) No. 22 — Chassis ground:

#3 (B134) No. 32 — Chassis ground:

#4 (B134) No. 13 — Chassis ground:

Is the resistance 1 M? or more?

Diagnostics for Engine Starting Failure > FUEL INJECTOR CIRCUIT">Go to Step 5.

Repair the short circuit to ground in harness between ECM connector and fuel injector connector.

5.CHECK EACH FUEL INJECTOR.

Measure the resistance between each fuel injector terminals.

Terminals

No. 1 — No. 2:

Is the resistance 5 — 20 ??

Diagnostics for Engine Starting Failure > FUEL INJECTOR CIRCUIT">Go to Step 6.

Replace the faulty fuel injector. Fuel Injector">

6.CHECK FOR POOR CONTACT.

Check for poor contact of ECM connector.

Is there poor contact of ECM connector?

Repair the poor contact of ECM connector.

Inspection using “General Diagnostic Table” General Diagnostic Table > INSPECTION">

Fuel pump circuit

Fuel pump circuit

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostics for Engine Starting FailureFUEL PUMP CIRCUITCAUTION:After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION&q ...

Other materials:

Dtc b2276 acc relay off signal

KEYLESS ACCESS WITH PUSH BUTTON START SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B2276 ACC RELAY OFF SIGNALDTC detecting condition:When input error occurs in accessory relay cut input signal of keyless access CM.Trouble symptom:• The accessory power su ...

Wheel replacement

When replacing wheels due, for example,

to damage, make sure the replacement

wheels match the specifications of the

wheels that are fitted as standard equipment.

Replacement wheels are available

from SUBARU dealers.

WARNING

Use only those wheels that are

specified for your vehicle. Wheels

...

Dtc b1630 curtain airbag sensor rh failure

AIRBAG SYSTEM (DIAGNOSTICS) > Diagnostic Chart with Trouble CodeDTC B1630 CURTAIN AIRBAG SENSOR RH FAILUREDIAGNOSIS START CONDITION:Ignition voltage is 10 V to 16 V.DTC DETECTING CONDITION:Curtain airbag sensor (RH) is faulty.If DTC B1630 is displayed, the circuit within the curtain airbag sensor ...