Subaru Crosstrek Service Manual: Electrical specification

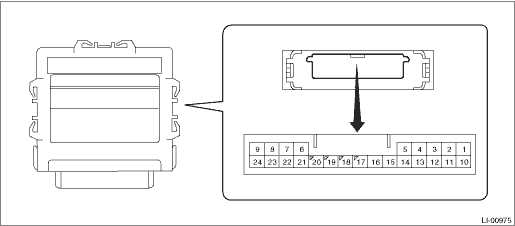

AUTO HEADLIGHT BEAM LEVELER SYSTEM (DIAGNOSTICS) > Control Module I/O Signal

ELECTRICAL SPECIFICATION

1. AUTO HEADLIGHT BEAM LEVELER CM

Content | Terminal No. | Measuring condition | Standard |

IG power supply | 1 ←> Chassis ground | Ignition switch ON | 8 — 16 V |

GND | 2 ←> Chassis ground | Always | Less than 1 ? |

Rr vehicle height sensor GND | 3 ←> Chassis ground | Always | Less than 1 ? |

Indicator output | 6 ←> Chassis ground | After turning the ignition switch to ON, for 3 seconds (warning light on) > after 3 seconds (warning light off) | Less than 1.35 V > 8 — 16 V |

Leveling actuator power supply | 10 ←> Chassis ground | Ignition switch ON | 10 — 16 V |

Leveling actuator GND | 11 ←> Chassis ground | Always | Less than 1 ? |

Rr vehicle height sensor power supply | 12 ←> 3 | Ignition switch ON | 4.75 — 5.25 V |

Leveling actuator signal | 17 ←> Chassis ground | Headlight off > on | Less than 1 V > 1.0 — 14.4 V (for 17 seconds) |

Headlight on, no vehicle height change > change and hold vehicle height for 3 seconds or more | |||

Rr sensor signal | 19 ←> Chassis ground | IG ON (with no passenger, no load and vehicle stopped) | Approx. 2.5 V (changes according to vehicle condition) |

CAN-H | 23 | Cannot be measured (CAN communication line) | — |

CAN-L | 24 | Cannot be measured (CAN communication line) | — |

Wiring diagram

Wiring diagram

AUTO HEADLIGHT BEAM LEVELER SYSTEM (DIAGNOSTICS) > Control Module I/O SignalWIRING DIAGRAMRefer to “Headlight Beam Leveler System” in the wiring diagram. Headlight Beam Leveler System ...

Other materials:

Changing the oil and oil filter

Change the oil and oil filter according to

the maintenance schedule in the "Warranty

and Maintenance Booklet".

The engine oil and oil filter must be

changed more frequently than listed in

the maintenance schedule when driving

on dusty roads, when short trips are

frequently made, or when dri ...

Dtc p0712 transmission fluid temperature sensor "a" circuit low

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0712 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT LOWDTC detecting condition:Immediately at fault recognitionTrouble symptom:• Excessive shift shock• Shift cha ...

Dtc u0151 lost communication with restraints control module

TELEMATICS SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC U0151 LOST COMMUNICATION WITH RESTRAINTS CONTROL MODULEDetected when CAN data is not received from airbag CM.NOTE:Perform the diagnosis for LAN system. Basic Diagnostic Procedure > PROCEDURE"> ...