Subaru Crosstrek Service Manual: Adjustment

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Front Differential Assembly

ADJUSTMENT

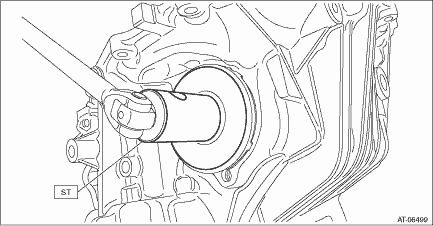

1. Using the ST, screw-in the retainer until resistance is felt.

NOTE:

RH side should be screwed-in more than LH side.

| ST 18658AA020 | WRENCH COMPL RETAINER |

2. Remove the remaining liquid gasket from the mating surface completely.

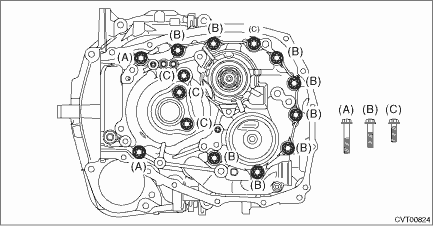

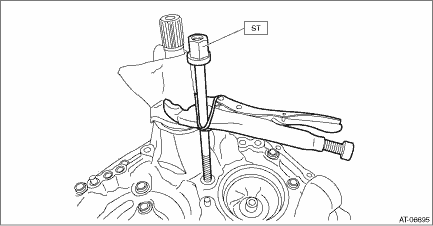

3. Using the ST, install the drive pinion assembly to converter case.

| ST 18270KA020 | SOCKET (E20) |

NOTE:

Do not confuse the three different-length bolts when installing.

Tightening torque:

43 N·m (4.4 kgf-m, 31.7 ft-lb)

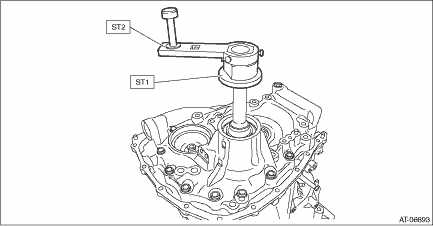

4. Rotate the drive pinion shaft ten times or more using ST1 and ST2.

| ST1 18667AA010 | HOLDER |

| ST2 499787700 | WRENCH |

5. While rotating the pinion shaft, tighten the retainer LH and loosen the retainer RH until the shaft can't be turned anymore. The backlash is “zero” when the pinion shaft comes to the point where it doesn't rotate.

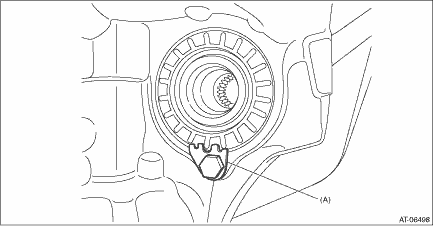

6. After the “zero” state is established, loosen the retainer LH by 3 notches and secure it with the lock plate. Retighten the retainer RH until it stops. Rotate the drive pinion 2 or 3 times. Tighten the retainer RH further 1-3/4 notches. This sets the preload. Finally, secure the retainer with its lock plate.

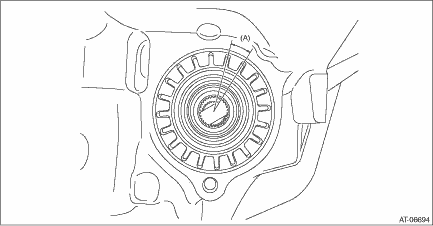

(A) | Lock plate |

NOTE:

Turning the retainer by every one tooth changes the backlash approx. 0.05 mm (0.0020 in).

(A) | 1 tooth |

7. Insert the two SUBARU genuine axle shafts into differential case.

| Part No. 38415AA070 | Axle shaft |

8. Install the ST to the drive pinion retainer, and wrap the drive pinion shaft with cloth and pinch with vise pliers. Using a tie-wrap or a wire, fix the vise pliers to the ST.

Make sure the drive pinion shaft does not move.

| ST 18763AA000 | COMPRESSOR SHAFT |

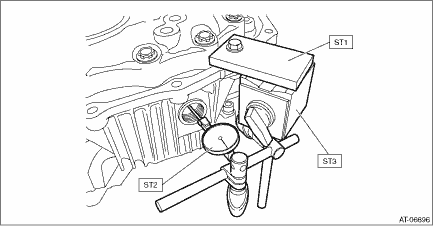

9. Check the backlash is within specification using ST1, ST2 and ST3.

| ST1 498255400 | PLATE |

| ST2 498247100 | DIAL GAUGE |

| ST3 498247001 | MAGNET BASE |

Backlash:

0.13 — 0.18 mm (0.005 — 0.007 in)

10. Adjust the teeth contact of the front differential and drive shaft. Drive Pinion Shaft Assembly > ADJUSTMENT">

Removal

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Front Differential AssemblyREMOVAL1. Remove the transmission assembly from the vehicle. Automatic Transmission Assembly > REMOVAL">2. Remove ...

Other materials:

Removal

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Purge Control Solenoid ValveREMOVAL1. Disconnect the ground cable from battery.2. Remove the bolt which holds the purge control solenoid valve onto intake manifold.NOTE:Hold the purge control solenoid valve unit by hand to prevent it from r ...

Dtc c1741 pressure sensor

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C1741 PRESSURE SENSORDTC detecting condition:Defective pressure sensorTrouble symptom:• ABS does not operate.• VDC does not operate.• Hill start assist does not operate.STEP ...

Removal

EXTERIOR/INTERIOR TRIM > Floor MatREMOVALCAUTION:• Before handling the airbag system components, refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">• Airbag system satellite safing sensor is lo ...