Subaru Crosstrek Service Manual: Wheel bearing Inspection

PERIODIC MAINTENANCE SERVICES > Wheel Bearing

INSPECTION

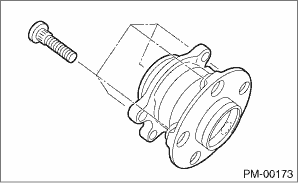

1. FRONT WHEEL BEARING

NOTE:

Inspect the condition of front wheel bearing grease.

1. Jack-up the front side of vehicle.

2. While holding the front wheel by hand, swing it in and out to check bearing free play.

3. Loosen the wheel nuts, and remove the front wheel.

4. If the bearing free play exists in step 2) above, attach a dial gauge to the hub and measure axial play in axial direction.

Service limit:

Straight-ahead position within 0.05 mm (0.0020 in)

5. Remove the bolts and self-locking nuts, and extract the front arm from front crossmember.

6. Remove the joint of front drive shaft from transmission. Front Axle">

7. While supporting the front drive shaft horizontally with one hand, turn the hub with the other hand to check for noise or binding.

If the hub is noisy or binds, replace the front axle.

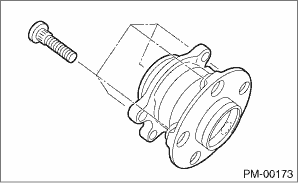

2. REAR WHEEL BEARING

1. Jack-up the rear side of vehicle.

2. While holding the rear wheel by hand, swing it in and out to check bearing free play.

3. Loosen the wheel nuts, and remove the rear wheel.

4. If the bearing free play exists in step 2) above, attach a dial gauge to the hub and measure axial play in axial direction.

Service limit:

Straight-ahead position within 0.05 mm (0.0020 in)

5. Remove the joint of rear drive shaft from rear differential. Rear Drive Shaft">

6. While supporting rear drive shaft horizontally with one hand, turn the hub with the other hand to check for noise or binding.

If the hub is noisy or binds, replace the rear axle.

Tire inspection and rotation Inspection

Tire inspection and rotation Inspection

PERIODIC MAINTENANCE SERVICES > Tire Inspection and RotationINSPECTIONRefer to “WT” section for tire inspection and rotation. Tire and Wheel > INSPECTION"> ...

Other materials:

List

AUTO HEADLIGHT BEAM LEVELER SYSTEM (DIAGNOSTICS) > Read Current DataLISTItem NameContentStandardNoteTrip Count [count]Time stamp information, trip counter — — CountTime stamp information, original counter identification information — — Time Count [msec]Time stamp information, time count ...

Seatbelt warning light and chime

Your

vehicle is equipped with a seatbelt

warning device at the driver's and front

passenger's seat, as required by current

safety standards.

With the ignition switch turned to the "ON"

position, this device reminds the driver

and front passenger to fasten their seatbelts

by illuminating ...

Dtc b28a0 vehicle model judgment

EyeSight (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B28A0 VEHICLE MODEL JUDGMENTDetected when the model code for stereo camera and the model code used for CAN data are different.DTC DETECTING CONDITION:• Defective CAN system• Defective stereo camera&bul ...