Subaru Crosstrek Service Manual: Specification

DIFFERENTIALS > General Description

SPECIFICATION

1. REAR DIFFERENTIAL

When replacing a rear differential assembly, select the correct one according to the following table.

NOTE:

• Using a different rear differential assembly will cause the drive train and tires to drag or emit abnormal noise.

• For option code, refer to “ID” section.

Model | 2.0 L non-turbo | ||

CVT | 5MT | ||

Rear differential type | VA1-type | T-type | |

Identification | XD | 41 | TP |

LSD type | — | ||

Type of gear | Hypoid gear | ||

Gear ratio (number of gear teeth) | 3.700 (37/10) | 4.444 (40/9) | |

Oil capacity | 0.8 L (0.8 US qt, 0.7 Imp qt) | ||

Rear differential gear oil | GL–5 (75W-90) | ||

2. IDENTIFICATION

Identification positions are shown in the following figures. For details concerning identification, refer to the “ID” section.

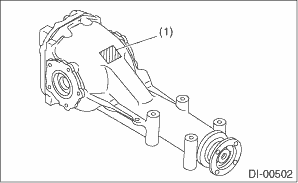

• T-type

(1) | Identification |

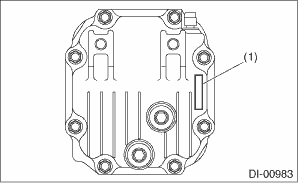

• VA1-type

(1) | Identification |

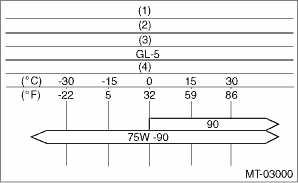

3. REAR DIFFERENTIAL GEAR OIL

Recommended gear oil:

GL–5 (75W–90) or equivalent

CAUTION:

Each oil manufacturer has its base oil and additives. Thus, do not mix two or more brands.

(1) | Item |

(2) | Rear differential gear oil |

(3) | API classification |

(4) | SAE viscosity No. and applicable temperature |

4. SERVICE DATA

Drive pinion bearing preload (for new bearing) | Measured with spring measurement (measured from the companion flange bolt) | N (kgf, lbf) | T-type | 18.1 — 38.8 (1.8 — 4.0, 4.1 — 8.7) |

VA1-type | 12.7 — 32.2 (1.3 — 3.3, 2.9 — 7.2) | |||

Measured with torque wrench | N·m (kgf-m, ft-lb) | T-type | 0.69 — 1.47 (0.07 — 0.15, 0.51 — 1.08) | |

VA1-type | 0.48 — 1.22 (0.05 — 0.12, 0.35 — 0.90) | |||

Side gear backlash | mm (in) | T-type | 0.10 — 0.20 (0.004 — 0.008) | |

VA1-type | 0.05 — 0.15 (0.002 — 0.006) | |||

Hypoid driven gear backlash | mm (in) | T-type | 0.10 — 0.20 (0.004 — 0.008) | |

VA1-type | 0.10 — 0.15 (0.004 — 0.006) | |||

Hypoid driven gear runout on its back surface | mm (in) | T-type | 0.05 (0.002) | |

Total preload (measured from the companion flange bolt hole) | N (kgf, lbf) | T-type | 20.7 — 54.4 (2.1 — 5.5, 4.7 — 12.2) | |

Companion flange mating surface runout | mm (in) | 0.08 (0.003) | ||

Companion flange runout on its inner side | mm (in) | 0.08 (0.003) | ||

Caution

Caution

DIFFERENTIALS > General DescriptionCAUTION• When performing any work, always wear work clothes, a work cap and protective shoes. Additionally, wear a helmet, protective goggles, etc. if neces ...

Component

Component

DIFFERENTIALS > General DescriptionCOMPONENT1. REAR DIFFERENTIAL (T-TYPE)(1)Hypoid driven gear and drive pinion set(14)O-ring(27)Filler plug(2)Pinion height adjusting washer(15)Side retainer shim(2 ...

Other materials:

Uniform tire quality grading standards

This information indicates the relative

performance of passenger car

tires in the area of treadwear,

traction, and temperature resistance.

This is to aid the consumer

in making an informed choice in the

purchase of tires.

Quality grades can be found where

applicable on the tire sidewall ...

Inspection

SECURITY AND LOCKS > Door Lock Control SystemINSPECTION1. SYMPTOM CHARTSymptomsRepair orderReferenceThe door lock control system does not operate.1. Remove and visually inspect the following fuses.• No. 3 (in fuse & relay box)• No. 7 (in fuse & relay box)• No. 8 (in main ...

Dtc b1813 short in driver s airbag dual stage - 2nd step circuit (to +b)

AIRBAG SYSTEM (DIAGNOSTICS) > Diagnostic Chart with Trouble CodeDTC B1813 SHORT IN DRIVER’S AIRBAG DUAL STAGE - 2ND STEP CIRCUIT (TO +B)Diagnosis start condition:Ignition voltage is 10 V to 16 V.DTC detecting condition:• Airbag main harness circuit is shorted to power supply.• A ...