Subaru Crosstrek Service Manual: Installation

BRAKE > Rear Disc Brake Assembly

INSTALLATION

NOTE:

Before installation, remove mud and foreign matter from the caliper body assembly and support - rear disc brake.

1. Before installation, check each part. Rear Disc Brake Assembly > INSPECTION">

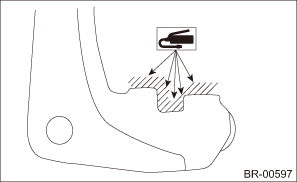

2. Apply a thin coat of grease to the support - rear disc brake.

Preparation items:

Grease: An item contained in the pad kit or equivalent

3. Install the support - rear disc brake to the housing assembly - rear axle.

Tightening torque:

Refer to “COMPONENT” of “General Description” for the tightening torque. General Description > COMPONENT">

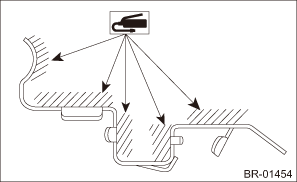

4. Apply a thin coat of grease to the pad clip.

Preparation items:

Grease: An item contained in the pad kit or equivalent

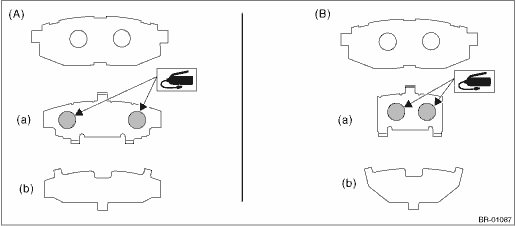

5. Apply a thin coat of grease to the shim - disc brake rear inner (a) and the shim - disc brake rear outer (b).

Preparation items:

Grease: Those contained in the pad kit or WAKO grease V160

(A) | Pad - disc brake rear outer | (B) | Pad - disc brake rear inner |

6. Install the brake pad to the support - rear disc brake.

7. Install the caliper body assembly to the support - rear disc brake.

Tightening torque:

Caliper bolt: 27 N·m (2.75 kgf-m, 19.9 ft-lb)

8. Install the brake hose bracket.

Tightening torque:

Brake hose bracket: 33 N·m (3.36 kgf-m, 14.3 ft-lb)

9. Connect the brake hose using a new brake hose gasket.

Tightening torque:

Union bolt: 26 N·m (2.65 kgf-m, 19.2 ft-lb)

10. Bleed air from the brake system. Air Bleeding > PROCEDURE">

11. Install the rear wheels.

Tightening torque:

Except for C4 model: 120 N·m (12.24 kgf-m, 88.5 ft-lb)

C4 model: 100 N·m (10.20 kgf-m, 73.8 ft-lb)

Inspection

Inspection

BRAKE > Rear Disc Brake AssemblyINSPECTION1. Check the caliper body cylinder and piston - disc brake for uneven wear, damage or rust.2. Check the rubber parts for damage or deterioration.3. If faul ...

Rear disc rotor

Rear disc rotor

...

Other materials:

Dtc u0151 lost communication with restraints control module

LAN SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC U0151 LOST COMMUNICATION WITH RESTRAINTS CONTROL MODULEDTC DETECTING CONDITION:No data is received from airbag CM.TROUBLE SYMPTOM:Cooperation control with airbag CM does not operate properly.STEPCHECKYESNO1.CHEC ...

Dtc c2543 error passive

POWER ASSISTED SYSTEM (POWER STEERING) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C2543 ERROR PASSIVETrouble symptom:The steering wheel operation feels heavy.STEPCHECKYESNO1.CHECK LAN SYSTEM.Perform the diagnosis for LAN system using the Subaru Select Monitor. Bas ...

Roof rail

Roof rail

Crossbar

Cargo can be carried on the roof after

securing the crossbars to the roof rails and

installing an appropriate carrying attachment.

When installing crossbars and a

carrying attachment, follow the manufacturer's

instructions. The roof rail system is

designed to car ...