Subaru Crosstrek Service Manual: Disassembly

DIFFERENTIALS > Rear Differential (VA-type)

DISASSEMBLY

To detect the real cause of trouble, inspect the following items before disassembling.

• Tooth contact and backlash between hypoid driven gear and drive pinion

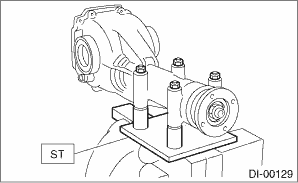

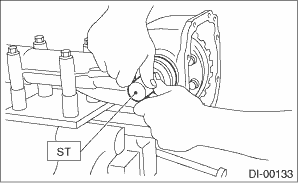

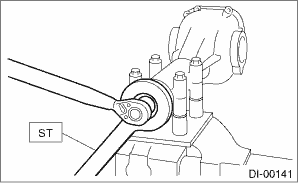

1. Set the ST on vise and install the differential assembly to ST.

| ST 398217700 | ATTACHMENT SET |

2. Remove the drain plug and filler plug.

3. Remove the rear cover by removing retaining bolts.

NOTE:

Remove it by tapping with a plastic hammer.

4. Remove the stud bolts from rear cover if necessary.

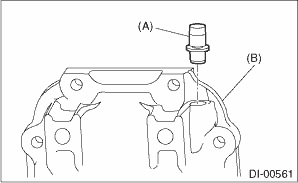

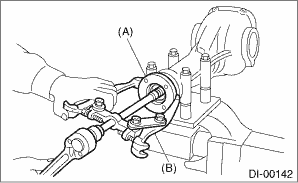

5. Remove the air breather cap.

NOTE:

• Do not attempt to remove the air breather cap unless necessary.

• Whenever the air breather cap is removed, replace it with a new part.

(A) | Air breather cap |

(B) | Rear cover |

6. Remove the lock plate RH and LH.

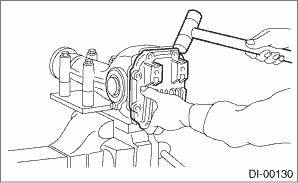

7. Remove the side retainer RH and LH with ST.

NOTE:

When keeping the retainers aside, use labels etc. to avoid confusing the left and right.

| ST 18630AA010 | WRENCH COMPL RETAINER |

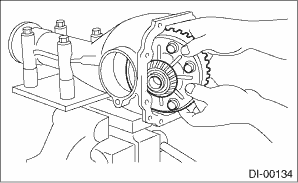

8. Pull out the differential case assembly from differential carrier.

NOTE:

Be careful not to hit the teeth of hypoid driven gear against the differential carrier.

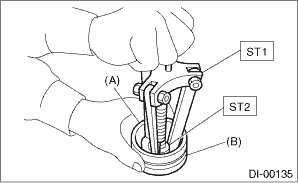

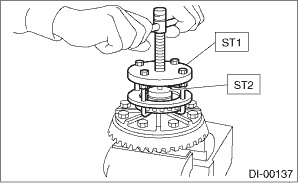

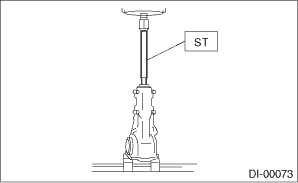

9. Remove the bearing race from side retainer RH and LH with ST1 and ST2.

| ST1 499705401 | PULLER ASSY |

| ST2 499705404 | SEAT |

(A) | Bearing race |

(B) | Side retainer |

10. Remove the oil seal from RH and LH side retainers.

NOTE:

Perform this operation only when changing oil seal.

11. Remove the O-rings.

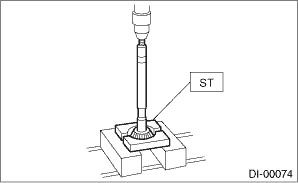

12. Remove the side bearing cone with ST1 and ST2.

NOTE:

• Do not attempt to disassemble the parts unless necessary.

• Set the puller so that its claws catch the edge of the side bearing cone.

• Store so that the right and left side bearing races and cones are not mixed together.

| ST1 899524100 | PULLER SET |

| ST2 399520105 | SEAT |

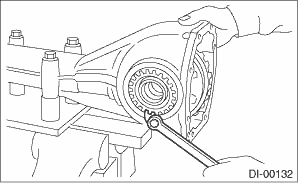

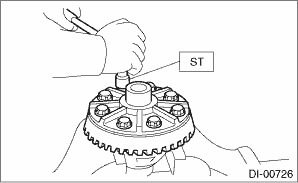

13. Using the ST, loosen the hypoid driven gear bolt and remove the hypoid driven gear.

| ST 18270KA020 | SOCKET (E20) |

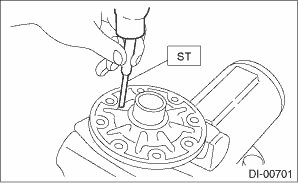

14. Remove the spring pin from hypoid driven gear side using ST.

| ST 899904100 | STRAIGHT PIN REMOVER |

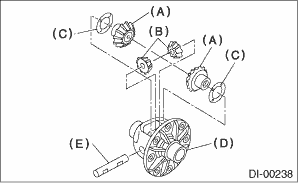

15. Draw out the pinion mate shaft and remove pinion mate gears, side gears and side gear thrust washers.

NOTE:

The gears and washers should be marked with RH or LH, front or rear, or kept separately.

(A) | Side gear |

(B) | Pinion mate gear |

(C) | Side gear thrust washer |

(D) | Differential case |

(E) | Pinion mate shaft |

16. Remove the self-locking nut while securing the companion flange with ST.

| ST 498427200 | FLANGE WRENCH |

17. Extract the companion flange with a puller.

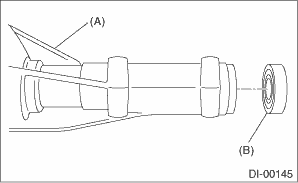

(A) | Companion flange |

(B) | Puller |

18. Press the end of drive pinion shaft using ST and remove the rear bearing cone, pinion height adjusting washer, preload adjusting spacer and washer.

NOTE:

Hold the drive pinion so as not to drop it.

| ST 398467700 | DRIFT |

19. Remove the rear bearing cone from drive pinion by supporting the bearing cone with ST.

NOTE:

Place the remover so that its center-recessed side faces the bearing cone.

| ST 498515500 | REMOVER |

20. Remove the front oil seal from differential carrier using ST.

| ST 398527700 | PULLER ASSY |

(A) | Differential carrier |

(B) | Front oil seal |

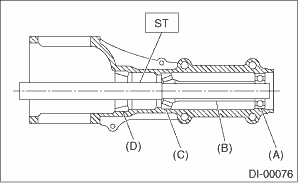

21. Remove the pilot bearing together with the front bearing cone and spacer using the ST.

| ST 398467700 | DRIFT |

(A) | Pilot bearing |

(B) | Spacer |

(C) | Front bearing |

(D) | Rear bearing race |

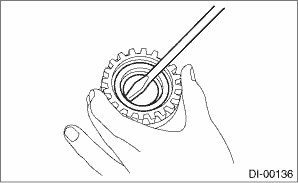

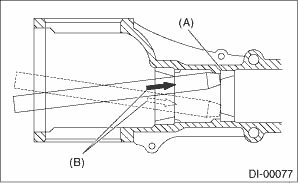

22. When replacing the bearings, tap out the front bearing race and rear bearing race in this order using a brass bar to remove them.

(A) | 2 cutout portions along diagonal lines |

(B) | Tap alternately with brass bar. |

Assembly

Assembly

DIFFERENTIALS > Rear Differential (VA-type)ASSEMBLYNOTE:• Assemble in the reverse order of disassembly.• Check and adjust each part during assembly.• Keep the shims and washers in ...

Inspection

Inspection

DIFFERENTIALS > Rear Differential (VA-type)INSPECTIONWash all the disassembled parts clean, and examine them for wear, damage or other defects. Repair or replace the defective parts as necessary.1. ...

Other materials:

Dtc c0041 ecm

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C0041 ECMDTC detecting condition:Defective VDCCM&H/UTrouble symptom:• ABS does not operate.• EBD does not operate.• VDC does not operate.• EyeSight does not operat ...

Dtc p0223 throttle/pedal position sensor/switch "b" circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0223 THROTTLE/PEDAL POSITION SENSOR/SWITCH "B" CIRCUIT HIGHDTC detecting condition:Immediately at fault recognitionTrouble symptom:• Improper idling• Poor driving performance• Engi ...

Note

LIGHTING SYSTEM > Auto Headlight Beam Leveler SystemNOTEFor operation procedures of each component of the auto headlight beam leveler system, refer to the respective section.• Auto headlight beam leveler CM: Auto Headlight Beam Leveler Control Module">• Vehicle height sensor: ...