Subaru Crosstrek Service Manual: Inspection

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Drive Pinion Shaft Assembly

INSPECTION

Disassembled parts should be washed with cleaning solvent first, then inspected carefully.

1. Bearing

Replace the bearings in the following cases.

• When the bearing balls, outer races and inner races are broken or rusty.

• When the bearing is worn.

• When the bearings fail to turn smoothly or emit noise in rotation after transmission gear oil has been applied.

• The double taper roller bearing on the rear side of the drive pinion shaft should be checked for smooth rotation before the drive pinion shaft assembly is disassembled. In this case, because a preload is working on the bearing, its rotation feels like it is slightly dragging unlike other bearings.

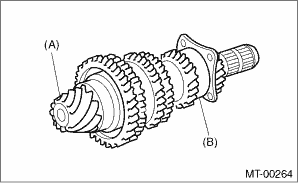

(A) | Drive pinion shaft |

(B) | Double taper roller bearing |

• When bearing has other defects.

2. Bushing (each gear)

Replace the bushing in following cases.

• When the sliding surface is damaged or abnormally worn.

• When the inner wall is abnormally worn.

3. Gear

Replace gears in the following cases.

• Replace the gear with new part if its tooth surfaces are broken, damaged or excessively worn.

• Correct or replace if the cone that contacts the baulk ring is rough or damaged.

• Correct or replace if the inner surface or end face is damaged.

4. Baulk ring, synchro cone

Replace the baulk ring and synchro cone in the following cases.

• When the inner surface and end face are damaged.

• When the baulk ring inner surface is abnormally or partially worn down.

• When the contact surface of the baulk ring insert section is cracked or abnormally worn.

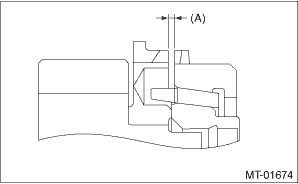

• If the gap between the end faces of the baulk ring and the gear splined part is excessively small, check the clearance (A) while pressing the ring against the cone.

Clearance (A):

0.5 mm (0.020 in) or more

• Apply transmission gear oil to the cone of the gear and while press-fitting the baulk ring, check there is no rotation in the circumferential direction.

5. Coupling sleeve and synchronizer hub

• Check the slipping condition of the coupling sleeve.

• Check the splines on the coupling sleeve and synchronizer hub for wear.

6. Shifting insert

Replace the shifting insert if deformed, excessively worn or defective in any way.

Disassembly

Disassembly

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Drive Pinion Shaft AssemblyDISASSEMBLYNOTE:Attach a cloth to the end of driven shaft (on the frictional side of the thrust needle bearing) to prevent dam ...

Installation

Installation

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Drive Pinion Shaft AssemblyINSTALLATION1. Remove the front differential assembly.2. Hypoid gear set match mark/No.: The number (A) on top of the drive pi ...

Other materials:

Adjustment

POWER ASSISTED SYSTEM (POWER STEERING) > Electric Power Steering GearboxADJUSTMENT1. GEARBOX BACKLASH ADJUSTMENT1. Remove the steering gearbox assembly. Electric Power Steering Gearbox > REMOVAL">2. Loosen the lock nut and adjusting screw.3. Apply a coat of grease to the sliding surfa ...

Installation

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > CVTF Cooler (With Warmer Function)INSTALLATION1. Install the CVTF cooler (with warmer feature) to the transmission.Tightening torque:23 N·m (2.3 kgf-m, 17.0 ft-lb)2. Install the engine coolant inlet hose.NOTE:With the triangle mark on the engine ...

Inspection

LIGHTING SYSTEM > Hazard SwitchINSPECTION1. Measure the resistance between connector terminals.Preparation tool:Circuit testerTerminal No.Inspection conditionsStandard2 — 3Switch OFF1 M? or moreSwitch ONLess than 1 ?2. Apply battery voltage between the connector terminals to check the lighting ...