Subaru Crosstrek Service Manual: Dtc p0345 camshaft position sensor "a" circuit bank 2

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P0345 CAMSHAFT POSITION SENSOR "A" CIRCUIT BANK 2

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

• Engine stall

• Failure of engine to start

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

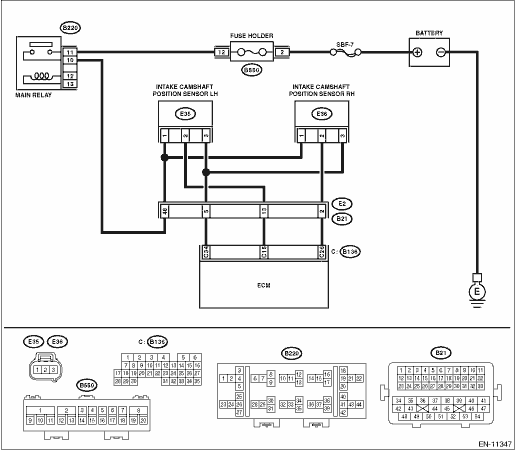

WIRING DIAGRAM:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK POWER SUPPLY OF CAMSHAFT POSITION SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from camshaft position sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between camshaft position sensor connector and engine ground.

Connector & terminal

(E35) No. 1 (+) — Engine ground (−):

Is the voltage 10 V or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0345 CAMSHAFT POSITION SENSOR "A" CIRCUIT BANK 2">Go to Step 2.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit or short circuit to ground in harness between main relay connector and camshaft position sensor connector

• Poor contact of coupling connector

2.CHECK HARNESS BETWEEN ECM AND CAMSHAFT POSITION SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Measure the resistance between ECM connector and camshaft position sensor connector.

Connector & terminal

(B136) No. 15 — (E35) No. 2:

(B136) No. 34 — (E35) No. 3:

Is the resistance less than 1 ??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0345 CAMSHAFT POSITION SENSOR "A" CIRCUIT BANK 2">Go to Step 3.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit in harness between ECM connector and camshaft position sensor connector

• Poor contact of coupling connector

3.CHECK HARNESS BETWEEN ECM AND CAMSHAFT POSITION SENSOR CONNECTOR.

Measure the resistance between camshaft position sensor connector and engine ground.

Connector & terminal

(E35) No. 2 — Engine ground:

Is the resistance 1 M? or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0345 CAMSHAFT POSITION SENSOR "A" CIRCUIT BANK 2">Go to Step 4.

Repair short circuit to ground in harness between ECM connector and camshaft position sensor connector.

4.CHECK HARNESS BETWEEN ECM AND CAMSHAFT POSITION SENSOR CONNECTOR.

Measure the voltage between camshaft position sensor connector and engine ground.

Connector & terminal

(E35) No. 2 (+) — Engine ground (−):

Is the voltage 5 V or more?

Repair the short circuit to power in the harness between ECM connector and camshaft position sensor connector.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0345 CAMSHAFT POSITION SENSOR "A" CIRCUIT BANK 2">Go to Step 5.

5.CHECK CONDITION OF CAMSHAFT POSITION SENSOR.

Is the camshaft position sensor installation bolt tightened securely?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0345 CAMSHAFT POSITION SENSOR "A" CIRCUIT BANK 2">Go to Step 6.

Tighten the camshaft position sensor installation bolt securely.

6.CHECK CAMSHAFT POSITION SENSOR.

Check the waveform of the camshaft position sensor. Engine Control Module (ECM) I/O Signal">

Is there any abnormality in waveform?

Replace the camshaft position sensor. Camshaft Position Sensor">

Repair the following item.

• Poor contact of ECM connector

• Poor contact of camshaft position sensor connector

• Poor contact of coupling connector

1. OUTLINE OF DIAGNOSIS

NOTE:

For the detection standard, refer to DTC P0340. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0340 CAMSHAFT POSITION SENSOR "A" CIRCUIT BANK 1 OR SINGLE SENSOR">

Dtc p0341 camshaft position sensor "a" circuit range/performance bank 1 or single sensor

Dtc p0341 camshaft position sensor "a" circuit range/performance bank 1 or single sensor

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0341 CAMSHAFT POSITION SENSOR "A" CIRCUIT RANGE/PERFORMANCE BANK 1 OR SINGLE SENSORNOTE:For the di ...

Dtc p0346 camshaft position sensor "a" circuit range/performance bank 2

Dtc p0346 camshaft position sensor "a" circuit range/performance bank 2

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0346 CAMSHAFT POSITION SENSOR "A" CIRCUIT RANGE/PERFORMANCE BANK 2NOTE:For the diagnostic procedur ...

Other materials:

Disassembly

DRIVE SHAFT SYSTEM > Rear Hub Unit BearingDISASSEMBLYUsing the ST or a hydraulic press, push out the hub bolt (b) from the rear hub unit bearing (a).CAUTION:• Be careful not to hammer the hub bolts. This may deform the hub unit bearing.• Do not reuse the hub bolt.NOTE:Since the rear h ...

Removal

MECHANICAL(H4DO) > Crank SprocketREMOVALNOTE:When replacing a single part, perform the work with the engine assembly installed to body.1. Remove the chain cover. Chain Cover > REMOVAL">2. Remove the timing chain. Timing Chain Assembly > REMOVAL">3. Remove the crank sprocke ...

Wiring diagram

WIPER AND WASHER SYSTEMS > Wiper and Washer SystemWIRING DIAGRAM1. WIPER AND WASHER (FRONT)Refer to “Front Wiper and Washer System” in the wiring diagram. Front Wiper and Washer System > WIRING DIAGRAM">2. WIPER AND WASHER (REAR)Refer to “Rear Wiper and Washer System ...