Subaru Crosstrek Service Manual: Removal

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Leak Check Valve Assembly

REMOVAL

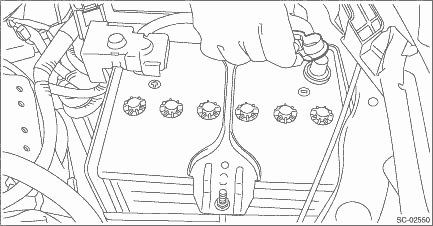

1. Disconnect the ground cable from battery.

2. Lift up the vehicle.

3. Remove the rear exhaust pipe. Rear Exhaust Pipe > REMOVAL">

4. Remove the propeller shaft. Propeller Shaft > REMOVAL">

5. Support the rear differential with the transmission jack.

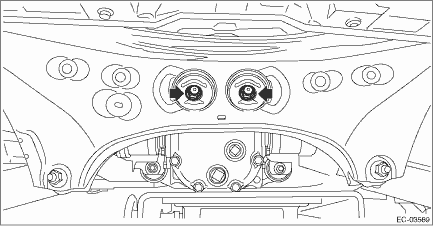

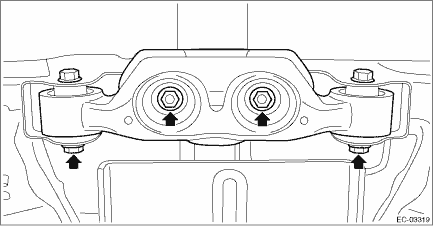

6. Remove the self-locking nuts which hold the rear differential to the rear sub frame assembly.

7. Remove the rear differential member from the rear sub frame assembly and the rear differential.

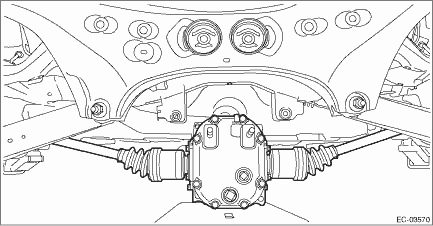

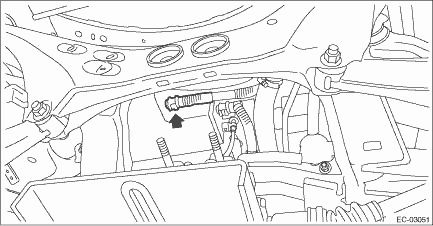

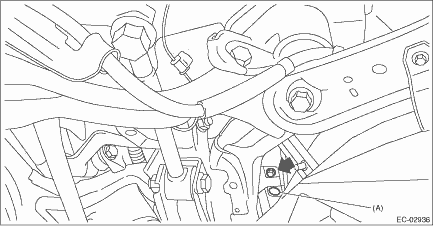

8. Lower the transmission jack gradually until the rear differential is at the position shown in the figure.

NOTE:

• When pulling out the stud bolt from the bushing portion of the rear sub frame assembly, adjust the angle and location of transmission jack and jack stand.

• Do not lower the rear differential excessively. Doing so may add extra load to the drive shaft or cause the falling-off of the drive shaft.

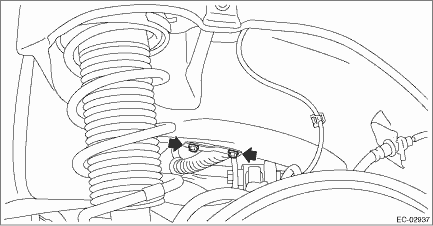

9. Disconnect the drain tube from the canister.

NOTE:

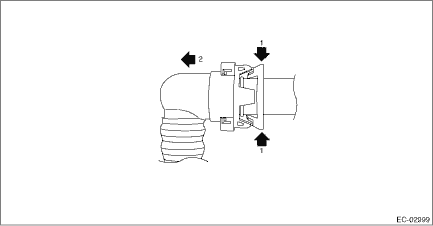

Disconnect the quick connector as shown in the figure.

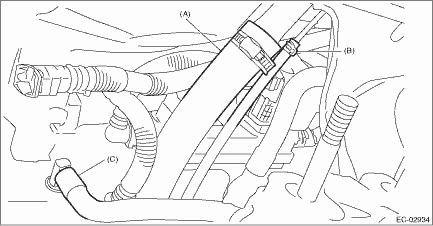

10. Disconnect the fuel filler hose (A) and evaporation hose (B).

11. Disconnect the intake hose (C) from the connector.

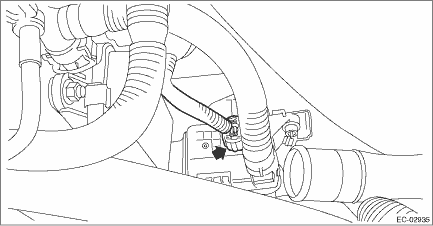

12. Disconnect the connector from the leak check valve assembly.

13. Remove the bolt and clip (A) which secure the leak check valve assembly to the vehicle, and remove the leak check valve assembly.

Assembly

Assembly

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Leak Check Valve AssemblyASSEMBLY1. Install the bracket to the leak check valve assembly.Tightening torque:18 N·m (1.8 kgf-m, 13.3 ft ...

Disassembly

Disassembly

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Leak Check Valve AssemblyDISASSEMBLY1. Remove the drain separator from the leak check valve assembly. Drain Separator > REMOVAL"> ...

Other materials:

Installation

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Transfer Drive GearINSTALLATION1. Install the transfer drive gear.Tightening torque:26 N·m (2.7 kgf-m, 19.2 ft-lb)2. Select the adjusting washer. Transfer Case and Extension Case Assembly > INSTALLATION">3. Install the transfer driven ...

Installation

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Engine Control Module (ECM)INSTALLATIONInstall in the reverse order of removal.CAUTION:• When the ECM of model with immobilizer has been replaced, be sure to perform the registration of immobilizer system.• For model without keyless access with pu ...

Adjustment

WIPER AND WASHER SYSTEMS > Front Washer Nozzle and HoseADJUSTMENT1. NOZZLE - WINDSHIELD WASHER1. Turn the wiper switch to OFF position.2. While the vehicle is at a standstill, insert a precision screwdriver (A) or equivalent wrapped with protective tape into the clearance on the upper/lower side ...