Subaru Crosstrek Service Manual: Removal

CONTROL SYSTEMS > AT Shift Lock Solenoid and “P” Range Switch

REMOVAL

1. SOLENOID UNIT

1. Remove the AT select lever. Select Lever > REMOVAL">

2. Remove the spacer and gasket. Select Lever > DISASSEMBLY">

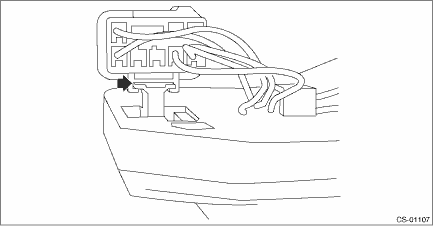

3. Using a flat tip screwdriver with a thin tip, remove the harness connector from the plate COMPL.

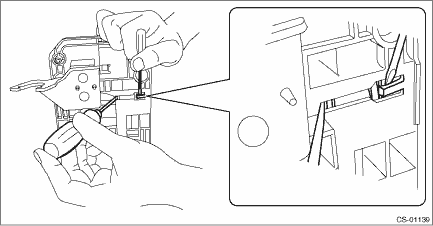

4. Raise the claw using a flat tip screwdriver with a thin tip, and remove the solenoid unit from the plate COMPL.

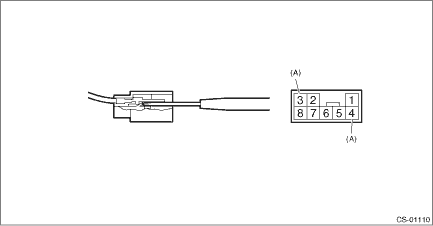

5. Remove the terminal of the solenoid unit using a flat tip precision screwdriver with a tip width of 1.3 mm (0.05 in) or less, KTC connector terminal tool ECC-1T or equivalent.

(A) | Solenoid unit terminals |

2. “P” RANGE SWITCH

For the removal of “P” range switch, refer to the procedure for AT select lever. Select Lever > DISASSEMBLY">

Inspection

Inspection

CONTROL SYSTEMS > AT Shift Lock Solenoid and “P” Range SwitchINSPECTIONSTEPCHECKYESNO1.CHECK SOLENOID UNIT.Measure the resistance of solenoid unit connector terminals.TerminalsNo. 4 — ...

Installation

Installation

CONTROL SYSTEMS > AT Shift Lock Solenoid and “P” Range SwitchINSTALLATIONInstall in the reverse order of removal.NOTE:Insert the solenoid unit terminals to the harness connector.(A)Sole ...

Other materials:

Inspection

POWER ASSISTED SYSTEM (POWER STEERING) (DIAGNOSTICS) > General DescriptionINSPECTIONBefore performing diagnosis, check the following items which might be affecting the power steering problem.1. BATTERYCheck the battery. Battery > INSPECTION">2. TIRESCheck the tire specifications, tire ...

Dtc c1221 front left abs sensor circuit

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C1221 FRONT LEFT ABS SENSOR CIRCUITNOTE:For the diagnostic procedure, refer to “DTC C1241 REAR LEFT ABS SENSOR CIRCUIT”. Diagnostic Procedure with Diagnostic Trouble Code (DTC) & ...

General diagnostic table Inspection

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > General Diagnostic TableINSPECTION1. MANUAL TRANSMISSIONSymptomsPossible causeCorrective action1. Gears are difficult to intermesh.NOTE:The cause for difficulty in shifting gears can be classified into two types: One is a defective gear shift system and ...