Subaru Crosstrek Service Manual: Removal

BRAKE > Brake Booster

REMOVAL

CAUTION:

• Do not allow brake fluid to come in contact with the painted surface of the vehicle body. If it does, wash off with water and wipe away completely.

• Before handling the airbag system components, always refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">

1. Disconnect the ground cable from battery and wait for at least 60 seconds before starting work. NOTE">

2. Remove the column assembly - steering. Steering Column > REMOVAL">

3. Drain brake fluid from the reservoir tank completely.

4. Disconnect the air conditioner pipe. Hose and Pipe > REMOVAL">

5. Remove the power steering control module. Power Steering Control Module > REMOVAL">

6. Remove the master cylinder assembly. Master Cylinder > REMOVAL">

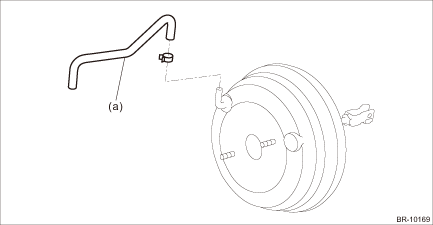

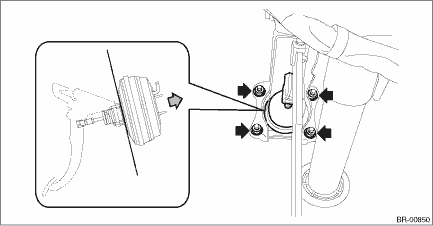

7. Remove the clamp and remove the vacuum hose (a).

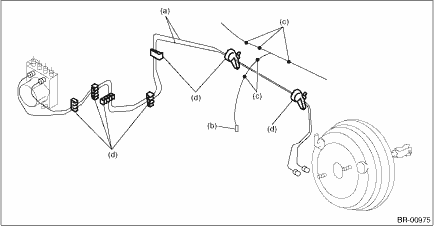

8. Remove the brake pipe assembly (a).

(1) Disconnect the starter connector (b) and harness clip (c).

(2) Remove the brake pipe assembly (a) from the pipe clip (d).

9. Remove the cover assembly - instrument panel LWR driver. Instrument Panel Lower Cover > REMOVAL">

10. Remove the knee airbag module. Knee Airbag Module > REMOVAL">

11. Remove the column assembly - steering. Steering Column > REMOVAL">

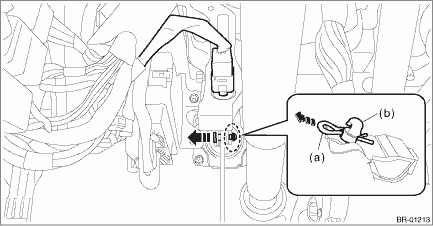

12. Remove the snap pin (a) and clevis pin (b), and remove the operating rod from the brake pedal.

CAUTION:

• Be careful not to apply excessive force to the operating rod when handling the operating rod. The angle may change by ±3°, and it may result in damage to power piston cylinder.

• Do not change the push rod length.

13. Remove the vacuum booster assembly.

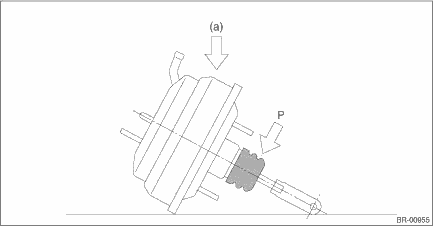

CAUTION:

• Do not disassemble the vacuum booster assembly.

• Make sure that the booster shell and vacuum pipe are not subject to strong impacts.

• Be careful not to drop the vacuum booster assembly. If the vacuum booster assembly is dropped accidentally, replace it.

• Be careful when placing the vacuum booster assembly on floor.

• If external force (a) is applied from above when the vacuum booster assembly is placed in this position, the resin portion as indicated by “P” may become damaged.

(1) Remove the nuts, and then remove the vacuum booster assembly.

Inspection

Inspection

BRAKE > Brake BoosterINSPECTION1. OPERATION CHECK WHEN NOT USING MEASURING DEVICESCAUTION:When checking operation, be sure to apply the parking brake securely.When an operation check is performed w ...

Installation

Installation

BRAKE > Brake BoosterINSTALLATION1. Check and adjust the operating rod of the vacuum booster assembly.(1) Measure the length between the vacuum booster assembly mounting surface and clevis pin hole ...

Other materials:

Installation

WIPER AND WASHER SYSTEMS > Front Washer Nozzle and HoseINSTALLATIONCAUTION:Before installing the windshield glass and cowl panel, make sure there are no gravel in the installing area.1. Install the nozzle - windshield washer.(1) Install the nozzle - windshield washer.(2) Install the hose - windsh ...

Specification

STARTING/CHARGING SYSTEMS(H4DO) > General DescriptionSPECIFICATIONItemSpecificationsVehicle modelCVTMTStarterTypeReduction typeModelM000T38571M000T33176ManufacturerMitsubishi ElectricVoltage and output12 V — 1.2 kW12 V — 1.0 kWDirection of rotationCounterclockwise (when observed from pinion)N ...

Registering a Bluetooth Audio device for the first time

To use the Bluetooth Audio, it is necessary

to register an audio device with the

system.

The device registration procedure is the

same for both the hands-free system and Bluetooth audio.

1. Display the "BT Devices Connection"

screen. Refer to "Registering a Bluetooth

phone for the first tim ...