Subaru Crosstrek Service Manual: Installation

DRIVE SHAFT SYSTEM > Rear Hub Unit Bearing

INSTALLATION

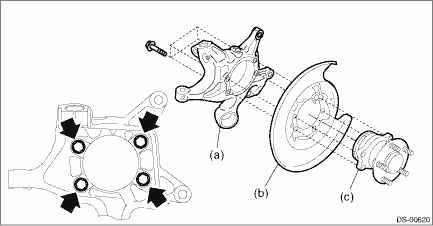

1. Place the rear brake back plate between the rear axle housing and the rear hub unit bearing, and tighten the bolt.

CAUTION:

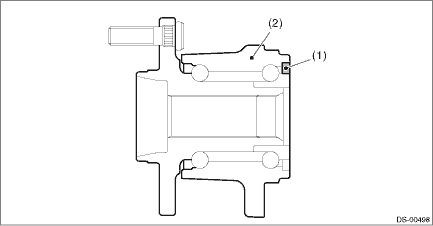

• Be careful not to damage the magnetic encoder.

• Do not get closer the tool which charged magnetism to magnetic encoder.

• Use a new bolt.

Tightening torque:

65 N·m (6.6 kgf-m, 47.9 ft-lb)

(1) | Magnetic encoder | (2) | Rear hub unit bearing |

(a) | Rear axle housing | (b) | Rear brake back plate | (c) | Rear hub unit bearing |

2. Install the rear drive shaft assembly.

CAUTION:

• Do not hammer the drive shaft assembly when installing.

• Use new axle nuts.

(1) Insert the drive shaft assembly into the hub spline, and pull it into the specified position.

(2) Tighten the axle nut temporarily.

3. Install the disc rotor to the rear hub unit bearing.

4. Install the caliper body assembly to the rear axle housing.

Tightening torque:

Refer to “COMPONENT” of “General Description” for the tightening torque. General Description > COMPONENT">

5. Install the brake hose bracket.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

6. Install the rear ABS wheel speed sensor.

Tightening torque:

7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

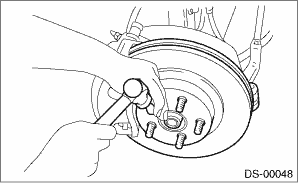

7. While pressing the brake pedal, tighten the new axle nuts to the specified torque.

CAUTION:

Do not load the rear axle before tightening the axle nut. Doing so may damage the hub unit bearing.

Tightening torque:

190 N·m (19.4 kgf-m, 140.1 ft-lb)

8. After tightening the axle nut, lock it securely.

9. Install the rear wheels, and perform the following inspections.

Tightening torque:

Except for C4 model: 120 N·m (12.2 kgf-m, 88.5 ft-lb)

C4 model: 100 N·m (10.2 kgf-m, 73.8 ft-lb)

(1) Check the wheels for smooth rotation.

(2) Check that there is no looseness by moving the upper and lower portions of rear tire in an axial direction with the brake pedal released.

• Looseness exists > Check the rear hub unit bearing. Rear Hub Unit Bearing > INSPECTION">

Inspection

Inspection

DRIVE SHAFT SYSTEM > Rear Hub Unit BearingINSPECTION1. Moving the rear tire up and down by hand, check there is no looseness in bearing, and check the wheel rotates smoothly.CAUTION:If there is uns ...

General diagnostic table Inspection

General diagnostic table Inspection

DRIVE SHAFT SYSTEM > General Diagnostic TableINSPECTIONNOTE:Vibration while cruising may be caused by an unbalanced tire, improper tire inflation pressure, improper wheel alignment, etc.SymptomsPos ...

Other materials:

Installation

LUBRICATION(H4DO) > Oil Level SwitchINSTALLATION1. Install the oil level switch and the clip (A) to the oil pan upper.NOTE:• Use new O-rings.• Apply a coat of engine oil to the O-rings.Tightening torque:6.4 N·m (0.7 kgf-m, 4.7 ft-lb)2. Install the engine mounting LH onto the en ...

Dtc p2096 post catalyst fuel trim system too lean bank 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2096 POST CATALYST FUEL TRIM SYSTEM TOO LEAN BANK 1DTC detecting condition:Detected when two consecutive driving cycles with fault occur.CAUTION:After servicing or replacing faulty parts, perform Clear Memory ...

Installation

POWER ASSISTED SYSTEM (POWER STEERING) > Universal JointINSTALLATION1. Before installation, check the universal joint assembly - steering. Universal Joint > INSPECTION">2. Adjust the tilt position of the column assembly - steering to the neutral position and lock the tilt lever.3. Ali ...