Subaru Crosstrek Service Manual: Installation

DRIVE SHAFT SYSTEM > Rear Drive Shaft

INSTALLATION

1. Replace the rear differential side oil seal. Rear Differential Side Oil Seal > REPLACEMENT">

NOTE:

After pulling out the drive shaft assembly, be sure to replace with a new oil seal.

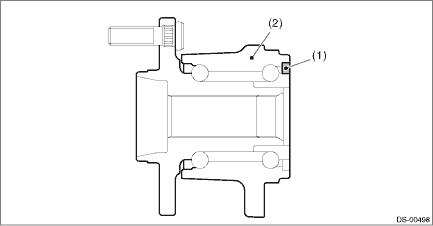

2. Insert the drive shaft assembly into the rear hub spline, and pull it into the specified position.

CAUTION:

• Be careful not to damage the magnetic encoder.

• Do not get closer the tool which charged magnetism to magnetic encoder.

• Do not hammer the drive shaft assembly when installing.

(1) | Magnetic encoder | (2) | Rear hub unit bearing |

3. Tighten the axle nut temporarily.

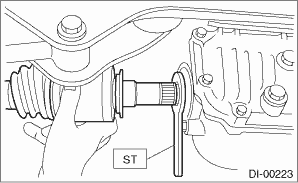

4. Using the ST, install the rear drive shaft assembly to the rear differential.

Preparation tool:

ST: OIL SEAL PROTECTOR (28099PA090)

5. Install the rear differential assembly to the rear sub frame assembly.

CAUTION:

Be sure to use a new self-locking nut.

Tightening torque:

Differential assembly — bushing - differential: 70 N·m (7.1 kgf-m, 51.6 ft-lb)

Differential assembly — rear sub frame assembly: 110 N·m (11.2 kgf-m, 81.1 ft-lb)

6. Install the sensor assembly - headlight beam leveler.

Tightening torque:

7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

7. While pressing the brake pedal, tighten the new axle nuts to the specified torque.

CAUTION:

Do not load the rear axle before tightening the axle nut. Doing so may damage the hub unit bearing.

Tightening torque:

190 N·m (19.4 kgf-m, 140.1 ft-lb)

8. Lock the axle nut securely.

9. Fill differential gear oil.

10. Install the rear wheels.

Tightening torque:

Except for C4 model: 120 N·m (12.2 kgf-m, 88.5 ft-lb)

C4 model: 100 N·m (10.2 kgf-m, 73.8 ft-lb)

11. Perform reinitialization of the auto headlight beam leveler system. (Model with auto headlight beam leveler) Auto Headlight Beam Leveler System > PROCEDURE">

Inspection

Inspection

DRIVE SHAFT SYSTEM > Rear Drive ShaftINSPECTIONCheck the removed parts for damage, wear, corrosion etc. Repair or replace if defective.• DOJ (Double Offset Joint):Check for seizure, corrosion ...

Other materials:

Location

WIPER AND WASHER SYSTEMS > Relay and FuseLOCATIONMain fuse boxFuse 30 A (wiper)(A)Relay & fuse boxFuse 7.5 A (wiper)(B)Relay holderWiper relay(C)NOTE:For other related fuses, refer to the wiring diagram. Power Supply Circuit"> ...

Removal

AIRBAG SYSTEM > Passenger’s Airbag ModuleREMOVALCAUTION:Before handling the airbag system components, refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">1. Turn the ignition switch to OFF.2. Disconne ...

Preparation tool

POWER ASSISTED SYSTEM (POWER STEERING) > General DescriptionPREPARATION TOOL1. SPECIAL TOOLILLUSTRATIONTOOL NUMBERDESCRIPTIONREMARKS34099PA100SPANNERUsed when measuring the rotational resistance of gearbox assembly. — SUBARU SELECT MONITOR 4Used for setting of each function and troubleshooting ...