Subaru Crosstrek Service Manual: Installation

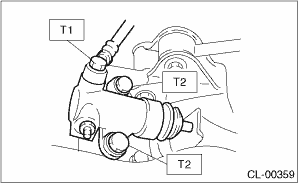

CLUTCH SYSTEM > Operating Cylinder

INSTALLATION

1. Install in the reverse order of removal.

NOTE:

• Before installing the operating cylinder, apply grease to the contact point of the release lever and operating cylinder.

Grease:

NICHIMOLY N-130 or equivalent

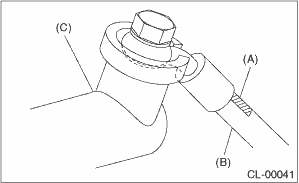

• Be sure to install the clutch hose with the mark side facing upward.

• Be careful not to twist the clutch hose during installation.

• Use a new gasket.

Tightening torque:

T1: 18 N·m (1.8 kgf-m, 13.3 ft-lb)

T2: 37 N·m (3.8 kgf-m, 27.3 ft-lb)

(A) | Mark |

(B) | Clutch hose |

(C) | Operating cylinder |

Tightening torque:

Air intake boot

3 N·m (0.3 kgf-m, 2.2 ft-lb)

2. After bleeding air from the operating cylinder, ensure that the clutch operates properly. Clutch Fluid Air Bleeding">

Inspection

Inspection

CLUTCH SYSTEM > Operating CylinderINSPECTION1. Check that the operating cylinder is not damaged. Replace the operating cylinder if it is damaged.2. Check the brake fluid leakage on the operating cy ...

Other materials:

Preparation tool

TELEMATICS SYSTEM (DIAGNOSTICS) > General DescriptionPREPARATION TOOL1. SPECIAL TOOLILLUSTRATIONTOOL NUMBERDESCRIPTIONREMARKS — SUBARU SELECT MONITOR 4Used for setting of each function and troubleshooting for electrical system.NOTE:For detailed operation procedures of Subaru Select Monitor 4, r ...

Fog light switch

Headlight switch

Fog light switch

The front fog lights will turn on when the

fog light switch is placed in the "

"

position while the headlights are in the

following condition.

while the headlight switch is in the "

"

position

for models with the auto on/off h ...

Installation

MECHANICAL(H4DO) > Cylinder HeadINSTALLATION1. CYLINDER HEAD RH1. Clean the bolt holes in the cylinder block RH.CAUTION:To avoid erroneous tightening of the bolts, clean out the bolt holes sufficiently by blowing with compressed air to eliminate engine coolant etc.2. Apply liquid gasket to both s ...