Subaru Crosstrek Service Manual: Inspection

CLUTCH SYSTEM > Release Bearing and Lever

INSPECTION

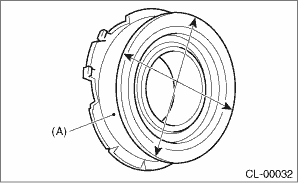

1. RELEASE BEARING

CAUTION:

Since this bearing is grease-sealed and is a non-lubrication type, do not wash with gasoline or any other solvent when servicing the clutch.

1. Check the bearing for smooth movement by applying force to the bearing in the radial direction.

Radial direction stroke:

1.4 mm (0.055 in) or more

(A) | Bearing case |

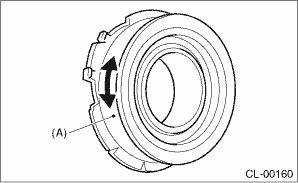

2. While applying force to the bearing in the rotational direction, check the bearing for smooth rotation.

(A) | Bearing case |

3. Check for wear and damage at the bearing case surface in contact with the lever.

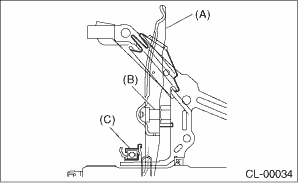

2. RELEASE LEVER

Check the pivot portion of the lever and the contact area with the release bearing case for wear.

(A) | Release lever |

(B) | Pivot |

(C) | Release bearing |

Removal

Removal

CLUTCH SYSTEM > Release Bearing and LeverREMOVAL1. Remove the transmission assembly from the vehicle. Manual Transmission Assembly > REMOVAL">2. Remove the two clips from the release lev ...

Other materials:

Dtc b11e0 rollover deployment history

AIRBAG SYSTEM (DIAGNOSTICS) > Diagnostic Chart with Trouble CodeDTC B11E0 ROLLOVER DEPLOYMENT HISTORYDIAGNOSIS START CONDITION:Ignition voltage is 10 V to 16 V.DTC DETECTING CONDITION:This DTC is indicated when the curtain airbag module and the seat belt pretensioner are deployed.Once this DTC is ...

Dtc b2a0f backup battery degradation

TELEMATICS SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B2A0F BACKUP BATTERY DEGRADATIONDIAGNOSIS START CONDITION:When ignition switch is ON.DTC DETECTING CONDITION:• Backup battery voltage of charger is low.• Charging attempt of 2 V or more fails ...

Headlight flasher

CAUTION

Do not hold the lever in the flashing

position for more than just a few

seconds.

To flash the headlights, pull the lever

toward you and then release it. The high

beam will stay on for as long as you hold

the lever. The headlight flasher works

even though the lighting switch is in ...