Subaru Crosstrek Service Manual: Inspection

CLUTCH SYSTEM > Clutch Switch

INSPECTION

1. CLUTCH START SWITCH

1. Perform the following inspections. If the clutch start switch does not operate normally, adjust the switch, and check it again. Clutch Switch > ADJUSTMENT">

• Make sure that engine does not start with clutch pedal not depressed.

• Make sure that engine starts with clutch pedal fully depressed.

2. When the clutch start switch does not operate normally even if it is adjusted, check the clutch start switch for continuity.

(1) Remove the clutch start switch. Clutch Switch > REMOVAL">

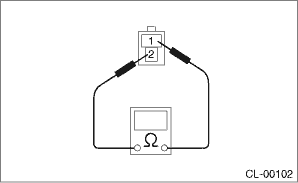

(2) Measure the resistance between terminal 1 and 2 of the switch. If the resistance is not at the standard value, replace the switch.

Condition | Terminal No. | Specified resistance |

ON | No. 1 — No. 2 | Less than 1 ? |

OFF | No. 1 — No. 2 | 1 M? or more |

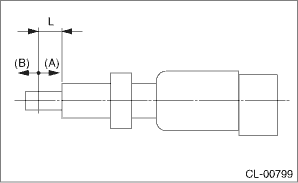

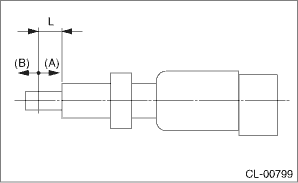

(3) Check that the switch is turned on and off in dimension L.

Dimension L:

9 — 10 mm (0.35 — 0.39 in)

(A) | ON |

(B) | OFF |

(4) Install the clutch start switch. Clutch Switch > INSTALLATION">

2. CLUTCH SWITCH

1. Check the clutch switch for continuity.

(1) Disconnect the connector of clutch switch.

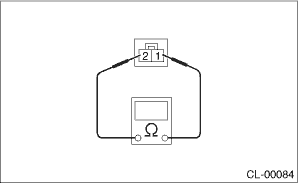

(2) Measure the resistance between terminal 1 and 2 of the switch. If the resistance is not within the specification, check the clutch stroke and installation condition, and check the clutch switch again.

Condition | Terminal No. | Specified resistance |

When clutch pedal is depressed | No. 1 — No. 2 | 1 M? or more |

When the clutch pedal is not depressed | No. 1 — No. 2 | Less than 1 ? |

2. When the clutch switch does not operate normally even if the clutch stroke and installation condition are normal, check the clutch switch for continuity.

(1) Remove the clutch switches. Clutch Switch > REMOVAL">

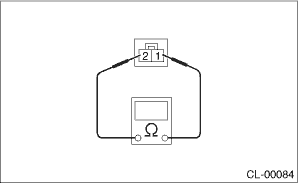

(2) Measure the resistance between terminal 1 and 2 of the switch. If the resistance is not at the standard value, replace the switch.

Condition | Terminal No. | Specified resistance |

ON | No. 1 — No. 2 | Less than 1 ? |

OFF | No. 1 — No. 2 | 1 M? or more |

(3) Check that the switch is turned on and off in dimension L.

Dimension L:

5 — 6.5 mm (0.2 — 0.26 in)

(A) | ON |

(B) | OFF |

(4) Install the clutch switch. Clutch Switch > INSTALLATION">

Removal

Removal

CLUTCH SYSTEM > Clutch SwitchREMOVALCAUTION:Before handling the airbag system components, refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. Genera ...

Installation

Installation

CLUTCH SYSTEM > Clutch SwitchINSTALLATION1. CLUTCH SWITCH1. Install the clutch switch.2. Move the clevis pin of push rod to left and right, retain it at the position where it moves smoothly, and me ...

Other materials:

Dtc c1421 ecm control system

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C1421 ECM CONTROL SYSTEMDTC detecting condition:ECM malfunctioningTrouble symptom:• ABS does not operate.• VDC does not operate.• Hill start assist does not operate.STEPCHEC ...

Dtc b1572 imm circuit except antenna circuit

KEYLESS ACCESS WITH PUSH BUTTON START SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B1572 IMM CIRCUIT EXCEPT ANTENNA CIRCUIT1. EXCEPT FOR C0 AND C5 MODELSDTC detecting condition:Communication error between keyless access CM and ECMTrouble symptom:Engine will no ...

Assembly

CLUTCH SYSTEM > Master CylinderASSEMBLY1. Apply a coat of grease to the contact surfaces of the push rod and piston before installation.Grease:SILICONE GREASE G-40M or equivalent2. Assemble in the reverse order of disassembly.Tightening torque:10 N·m (1.0 kgf-m, 7.4 ft-lb) ...