Subaru Crosstrek Service Manual: Dtc p0713 transmission fluid temperature sensor "a" circuit high

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT HIGH

DTC detecting condition:

Immediately at fault recognition

Trouble symptom:

• Excessive shift shock

• Shift characteristics malfunction

CAUTION:

Use the check board when measuring the TCM terminal voltage and resistance.

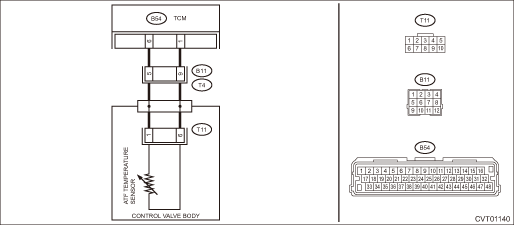

Wiring diagram:

CVT control system CVT Control System">

| STEP | CHECK | YES | NO |

1.CHECK HARNESS.

1) Turn the ignition switch to OFF.

2) Disconnect the TCM connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between TCM connectors.

Connector & terminal

(B54) No. 6 (+) — (B54) No. 1 (−):

Is the voltage 5 V or more?

Repair the short circuit of harness.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 2.

2.CHECK HARNESS.

1) Turn the ignition switch to OFF.

2) Disconnect the transmission connector.

3) Measure the resistance between TCM connector and transmission connectors.

Connector & terminal

(B54) No. 6 — (B11) No. 5:

(B54) No. 1 — (B11) No. 9:

Is the resistance less than 1 ??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 3.

Repair the open circuit of body harness.

3.CHECK ATF TEMPERATURE SENSOR.

Measure the resistance between transmission connector terminals.

Connector & terminal

(T4) No. 5 — No. 9:

Is the resistance 1 M? or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 4.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 5.

4.CHECK HARNESS.

CAUTION:

Start work after ATF cools down.

1) Remove the transmission valve cover.

2) Measure the resistance between transmission connector and control valve body connector.

Connector & terminal

(T4) No. 5 — (T11) No. 1:

(T4) No. 9 — (T11) No. 6:

Is the resistance less than 1 ??

Repair the open circuit of transmission harness on the control valve side.

Repair the open circuit of transmission harness on the outside of the transmission.

5.CHECK ATF TEMPERATURE SENSOR.

1) Connect all connectors.

2) Start the engine.

3) Warm up until the ATF temperature exceeds 50°C (122°F).

4) Turn the ignition switch to OFF.

5) Disconnect the transmission connector.

6) Measure the resistance between transmission connector terminals.

Connector & terminal

(T4) No. 5 — No. 9:

Is the resistance 650 — 990 ??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 6.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 8.

6.CHECK ATF TEMPERATURE SENSOR.

Measure the resistance between transmission connector terminals.

Connector & terminal

(T4) No. 5 — No. 9:

Does the resistance value increase gradually while the ATF temperature decreases?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 7.

Replace the control valve body. Control Valve Body">

7.CHECK INPUT SIGNAL FOR TCM.

1) Connect the connector to transmission.

2) Turn the ignition switch to ON. (Do not start engine.)

3) Read the data of «ATF Temp.» using the Subaru Select Monitor.

Does the ATF temperature gradually decrease?

Check for poor contact of the ATF temperature sensor and transmission connector harness, and repair the defective part.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 8.

8.CHECK FOR POOR CONTACT.

Is there poor contact of ATF temperature sensor circuit?

Repair the poor contact.

Replace the TCM. Transmission Control Module (TCM)">

1. OUTLINE OF DIAGNOSIS

• Detect short circuit to power supply or open circuit of the transmission oil temperature sensor 5 V system.

• Judge as NG if the voltage detected by the transmission oil temperature sensor is higher than the predetermined value.

2. EXECUTION CONDITION

Secondary Parameters | Execution condition |

12 V battery system voltage | ≥ 9 V |

Vehicle speed (calculated from secondary pulley speed) | ≥ 6.3 MPH |

Above condition satisfied for | ≥ 50 s |

3. DIAGNOSTIC METHOD

If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Malfunction Criteria | Threshold Value |

Measured Transmission fluid temperature sensor input voltage | > 4.507 V |

(Transmission fluid temperature) | (< − 52 degC) |

Time Needed for Diagnosis: 1 second

Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs.

Dtc p0712 transmission fluid temperature sensor "a" circuit low

Dtc p0712 transmission fluid temperature sensor "a" circuit low

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0712 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT LOWDTC detecting cond ...

Dtc p0716 input/turbine shaft speed sensor "a" circuit range/performance

Dtc p0716 input/turbine shaft speed sensor "a" circuit range/performance

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0716 INPUT/TURBINE SHAFT SPEED SENSOR "A" CIRCUIT RANGE/PERFORMANCEDTC detec ...

Other materials:

Odometer

Type A

Trip knob

Type B

Trip knob (U.S.-spec. models)

Trip knob (except U.S.-spec. models)

This meter displays the odometer when

the ignition switch is in the "ON" position.

The odometer shows the total distance

that the vehicle has been driven.

If you press the trip knob ...

Installation

EXTERIOR/INTERIOR TRIM > Instrument Panel AssemblyINSTALLATIONCAUTION:• Before handling the airbag system components, refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">• After installing the p ...

Engine cooling system trouble in general Inspection

COOLING(H4DO) > Engine Cooling System Trouble in GeneralINSPECTIONTroublePossible causeCorrective actionOver-heatinga. Insufficient engine coolantReplenish engine coolant, inspect for leakage, and repair it if necessary.b. Defective thermostatReplace.c. Malfunction of water pumpReplace.d. Clogged ...