Subaru Crosstrek Service Manual: Disassembly

CONTROL SYSTEMS > MT Gear Shift Lever

DISASSEMBLY

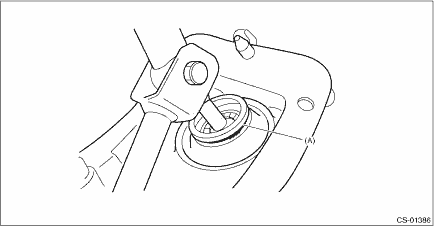

1. Remove the lock wires.

(A) | Lock wire |

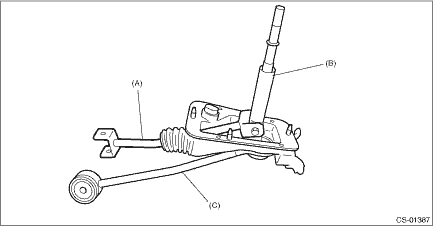

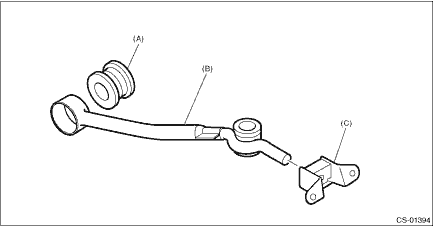

2. Remove the rod from gear shift lever.

(A) | Rod |

(B) | Lever |

(C) | Stay |

3. Separate the rod and inner boot.

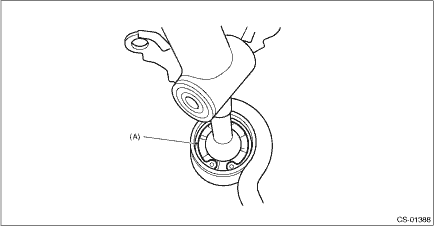

4. Remove the snap ring from the stay.

(A) | Snap ring |

5. Separate the gear shift lever and the stay.

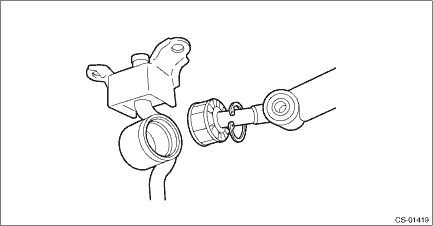

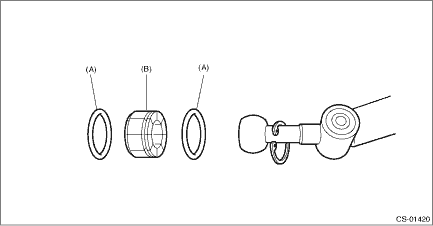

6. Remove the boot and bushing from the gear shift lever.

(A) | O-ring |

(B) | Bushing |

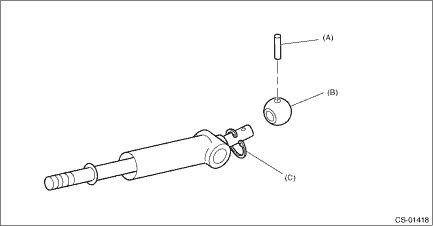

7. Remove the spring pin, and then remove the bushing and snap ring.

(A) | Spring pin |

(B) | Bushing |

(C) | Snap ring |

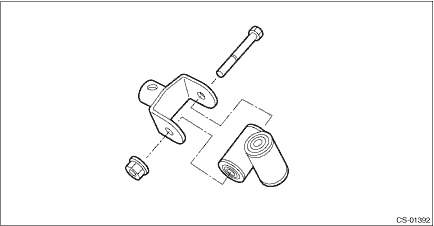

8. Remove the boss from the joint.

9. Remove the bushing and spacer from the boss.

(A) | Bushing |

(B) | Spacer |

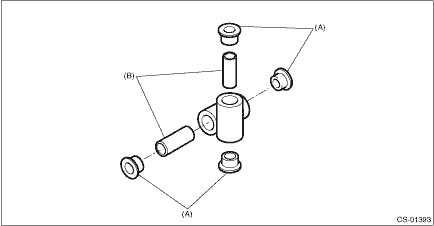

10. Remove the bushing and cushion rubber from the stay.

(A) | Bushing B |

(B) | Stay |

(C) | Cushion rubber |

Removal

Removal

CONTROL SYSTEMS > MT Gear Shift LeverREMOVAL1. Disconnect the ground cable from battery. NOTE">NOTE:For model with battery sensor, disconnect the ground terminal from battery sensor.2. Rem ...

Inspection

Inspection

CONTROL SYSTEMS > MT Gear Shift LeverINSPECTION1. Check the parts (bushing, cushion rubber, spacer, boot, stay and rod, etc.) for deformation, damage and wear. If necessary, correct or replace faul ...

Other materials:

Removal

SEATS > Seat Heater SystemREMOVAL1. SEAT HEATER UNIT1. Remove the front seats. Front Seat > REMOVAL">2. Remove the backrest cover of front seat and seat cushion cover. Front Seat > DISASSEMBLY">3. Remove the seat heater module.CAUTION:If the seat heater module is removed, ...

Airflow mode selection

To select the airflow mode:

Type A, B and C: Turn the airflow mode

selection dial.

Type D: Press the airflow mode selection

button.

To select the defrost mode:

Type A and B: Turn the airflow mode

selection dial.

Type C and D: Press the defroster button.

Airflow modes are as follows. ...

Wiring diagram

INSTRUMENTATION/DRIVER INFO > Combination Meter SystemWIRING DIAGRAMRefer to “Combination Meter System” in the wiring diagram.– Models with normal meters: Combination Meter System > WIRING DIAGRAM">– Model with color TFT meter: Combination Meter System > WIRING D ...