Subaru Crosstrek Service Manual: Disassembly

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Front Differential Assembly

DISASSEMBLY

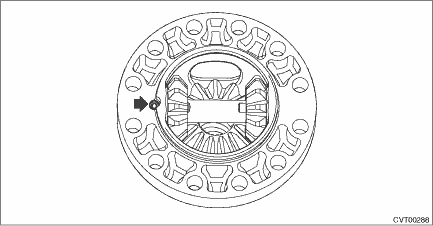

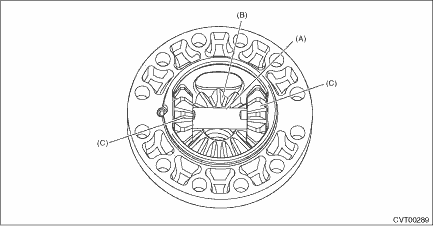

1. DIFFERENTIAL CASE ASSEMBLY

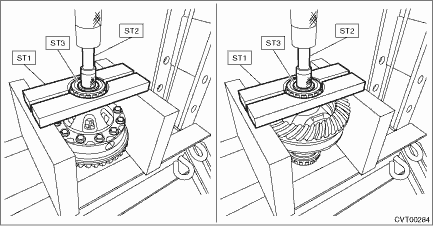

1. Remove the taper roller bearing using the ST.

| ST1 498077000 | REMOVER |

| ST2 899864100 | REMOVER |

| ST3 398497701 | SEAT |

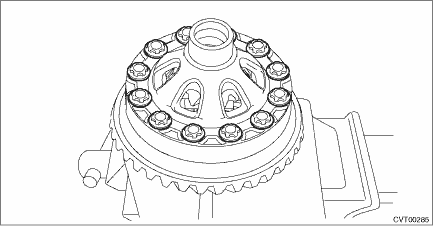

2. Remove the hypoid driven gear mounting bolt using the ST.

| ST 18270KA020 | SOCKET (E20) |

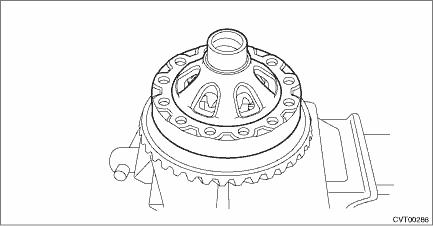

3. Remove the differential case (LH).

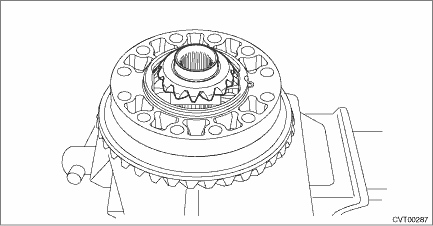

4. Remove the differential bevel gear and washer from differential case.

5. Remove the straight pin.

6. Remove the pinion shaft, then remove the differential bevel gear, washer and differential bevel pinion.

(A) | Pinion shaft |

(B) | Differential bevel gear |

(C) | Differential bevel pinion |

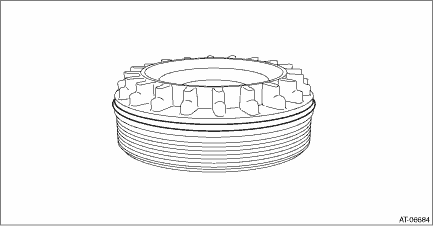

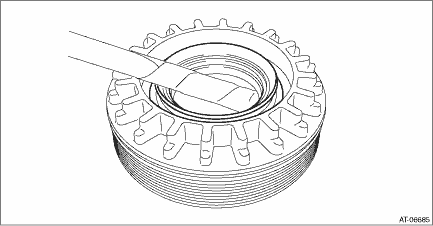

2. SIDE RETAINER

NOTE:

After adjusting the drive pinion backlash and tooth contact, replace the oil seal and O-ring with new parts.

1. Remove the O-ring.

2. Remove the oil seal.

Assembly

Assembly

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Front Differential AssemblyASSEMBLY1. DIFFERENTIAL CASE ASSEMBLY1. Install the washer and differential bevel gear into the differential case (RH).2. Inst ...

Inspection

Inspection

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Front Differential AssemblyINSPECTION• Check each component for scratches, damage or other faults.• Using the ST, check the backlash of pinio ...

Other materials:

Dtc u1235 lost communication with eyesight

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC U1235 LOST COMMUNICATION WITH EyeSightNOTE:Refer to “LAN SYSTEM (DIAGNOSTICS)” for diagnostic procedure. Basic Diagnostic Procedure">1. OUTLINE OF DIAGNOSIS• De ...

Installation

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Transfer Driven GearINSTALLATION1. Install the taper roller bearing (transfer case side) outer race.(A)Taper roller bearing (transfer case side) outer race(B)Transfer case2. Apply a coat of grease to the taper roller bearing (transfer case side) of tran ...

Two separate circuits

Your vehicle has two separate circuit

brake systems. Each circuit works diagonally

across the vehicle. If one circuit of

the brake system should fail, the other half

of the system still works. If one circuit fails,

the brake pedal will go down much closer

to the floor than usual and you will n ...