Subaru Crosstrek Service Manual: Adjustment

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Drive Pinion Shaft Assembly

ADJUSTMENT

1. Remove the liquid gasket from the mating surface completely.

2. Using the ST, install the drive pinion retainer to converter case.

| ST 18270KA020 | SOCKET (E20) |

NOTE:

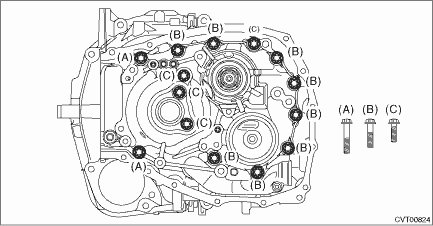

Do not confuse the three different-length bolts when installing.

Tightening torque:

43 N·m (4.4 kgf-m, 31.7 ft-lb)

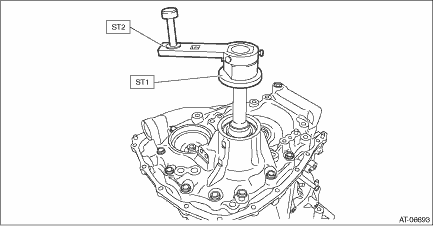

3. Rotate the drive pinion several times using ST1 and ST2.

| ST1 498937110 | HOLDER |

| ST2 499787700 | WRENCH |

4. Adjust the drive pinion and hypoid driven gear backlash. Front Differential Assembly > ADJUSTMENT">

5. Using the ST, remove the drive pinion retainer from converter case.

| ST 18270KA020 | SOCKET (E20) |

6. Apply lead-free red dye evenly on the both sides of three to four teeth of the hypoid driven gear. Then install the drive pinion retainer and rotate the drive pinion in both directions several times. Remove the drive pinion retainer and check the tooth contact pattern.

If the teeth contact is inappropriate, adjust the backlash or thickness of the shim. Front Differential Assembly > ADJUSTMENT">

NOTE:

After correction, wipe off the lead-free red dye.

Drive pinion shim | |

Part No. | Thickness mm (in) |

31451AA320 | 0.150 (0.0059) |

31451AA330 | 0.175 (0.0069) |

31451AA340 | 0.200 (0.0079) |

31451AA350 | 0.225 (0.0089) |

31451AA360 | 0.250 (0.0098) |

31451AA370 | 0.275 (0.0108) |

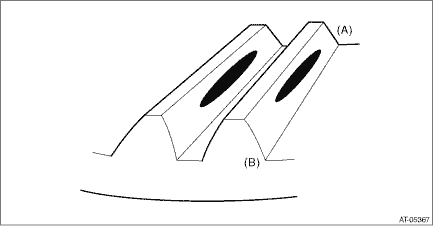

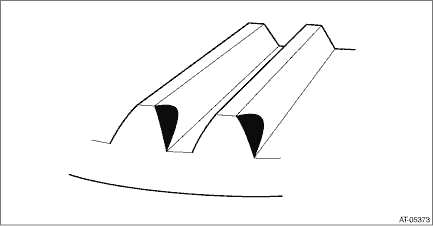

• Correct tooth contact

Check item: Tooth contact surface is slightly shifted toward the toe side under a no-load condition. (When driving, it moves towards the heel side.)

(A) | Toe side |

(B) | Heel side |

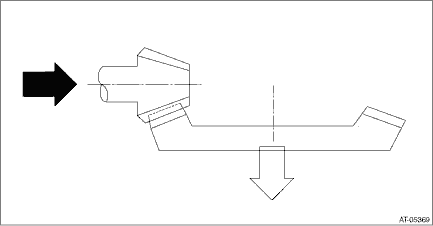

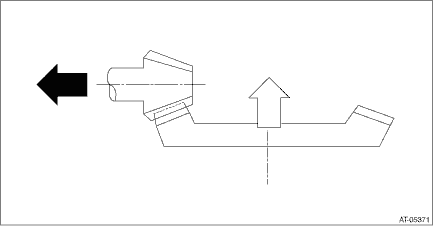

• Face contact

Check item: Backlash is too large.

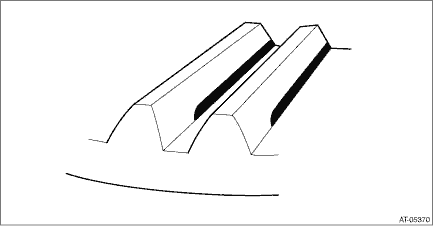

Contact pattern

Corrective action: Increase thickness of drive pinion shim according to the procedures for moving the drive pinion close to hypoid driven gear.

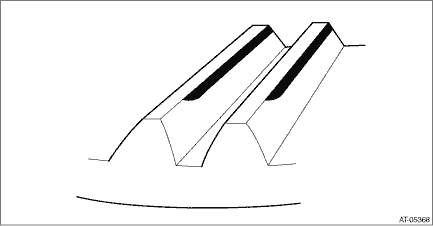

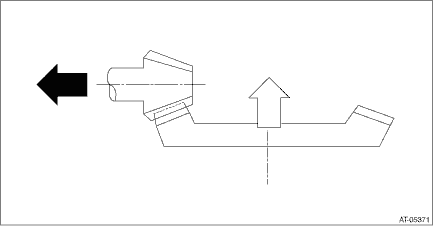

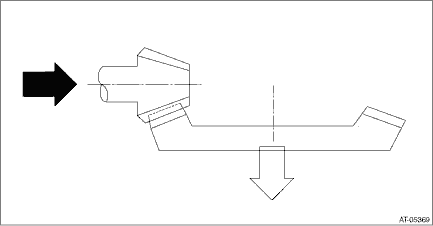

• Flank contact

Check item: Backlash is too small.

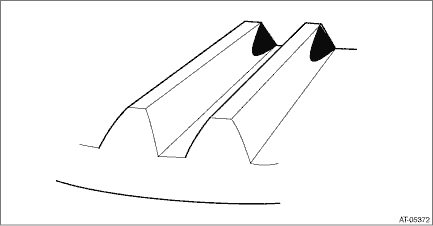

Contact pattern

Corrective action: Reduce the thickness of the drive pinion shim according to the procedures for moving the drive pinion away from the hypoid driven gear.

• Toe contact (inside contact)

Check item: Teeth contact area is too small.

Contact pattern

Corrective action: Reduce the thickness of the drive pinion shim according to the procedures for moving the drive pinion away from the hypoid driven gear side.

• Heel contact (outside end contact)

Check item: Teeth contact area is too small.

Contact pattern

Corrective action: Increase the thickness of the drive pinion shim according to the procedures for moving the drive pinion closer to the hypoid driven gear.

7. Using the ST, loosen the differential side retainer until the mounting groove of the O-ring appears, and then install the O-ring.

NOTE:

• When loosening the differential side retainer, record the number of the turns made.

• Perform this for both left and right differential side retainers.

• Use new O-rings.

• Apply the differential gear oil to O-ring.

| ST 18658AA020 | WRENCH COMPL RETAINER |

8. Using the ST, tighten the retainer to the position before it is loosened.

| ST 18658AA020 | WRENCH COMPL RETAINER |

9. Replace the differential side retainer oil seal with a new part. Differential Side Retainer Oil Seal">

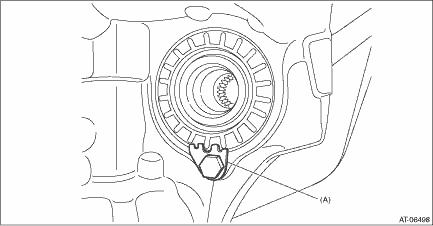

10. Install the lock plate.

Tightening torque:

25 N·m (2.5 kgf-m, 18.4 ft-lb)

(A) | Lock plate |

Removal

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Drive Pinion Shaft AssemblyREMOVAL1. Remove the transmission assembly from the vehicle. Automatic Transmission Assembly > REMOVAL">2. Remove ...

Other materials:

Disassembly

MECHANICAL(H4DO) > Cam CarrierDISASSEMBLY1. CAM CARRIER RH1. Loosen the bolts (front camshaft cap RH, intake center camshaft cap RH, intake rear camshaft cap RH, exhaust center camshaft cap RH, and exhaust rear camshaft cap RH) equally, a little at a time in numerical sequence as shown in the fig ...

Inspection

COOLING(H4DO) > RadiatorINSPECTION1. Check that the radiator does not have deformation, cracks or damage.2. Check that the hose has no cracks, damage or loose part.3. Remove the radiator cap, fill the radiator with engine coolant, and then install the radiator cap tester to the filler neck of rad ...

Dtc c2022 tire 2 air pressure low (normal mode)

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C2022 TIRE 2 AIR PRESSURE LOW (NORMAL MODE)NOTE:Refer to DTC C2024 for diagnostic procedure. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC C2024 TIRE 4 AIR PRESSURE LOW ( ...