Subaru Crosstrek Service Manual: Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transmission Mounting System

REMOVAL

1. PITCHING STOPPER

1. Disconnect the ground cable from battery. NOTE">

NOTE:

For model with battery sensor, disconnect the ground terminal from battery sensor.

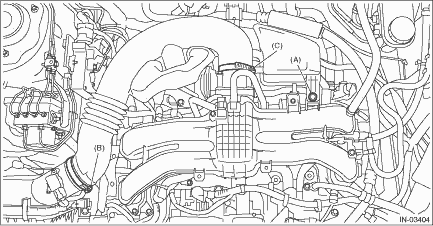

2. Remove the clip (A) from the air intake boot.

3. Loosen the clamp (B) connecting the air intake boot and air cleaner case (rear).

4. Loosen the clamp (C) which connects the air intake boot and throttle body.

5. Remove the air intake boot from the throttle body, and move it to the left side wheel apron.

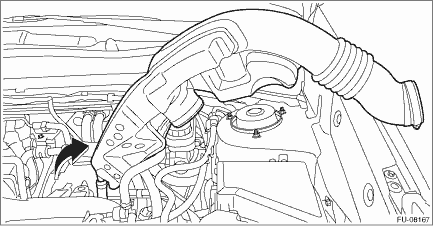

6. Remove the pitching stopper.

2. TRANSMISSION REAR CROSSMEMBER AND REAR CUSHION RUBBER

1. Disconnect the ground cable from battery. NOTE">

NOTE:

For model with battery sensor, disconnect the ground terminal from battery sensor.

2. Lift up the vehicle.

3. Remove the center exhaust pipe. Center Exhaust Pipe > REMOVAL">

4. Remove the center exhaust cover.

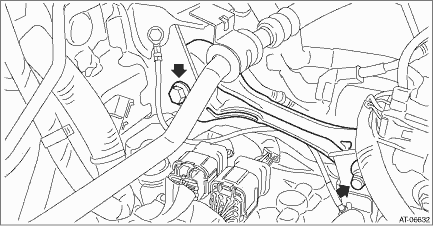

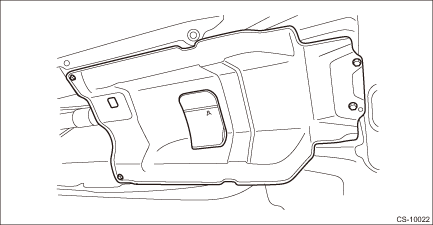

5. Set the transmission jack under the transmission. Make sure that the support plate of transmission jack does not touch the oil pan.

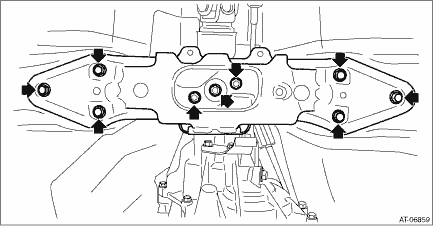

6. Remove the transmission rear crossmember.

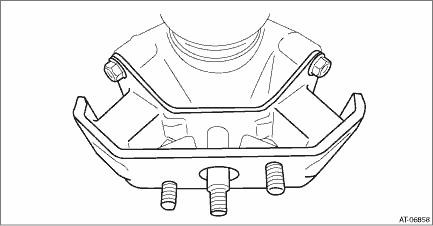

7. Remove the rear cushion rubber.

Inspection

Inspection

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transmission Mounting SystemINSPECTION• Check the crossmember for bends or damage.• Check that the cushion rubber is not stiff, cracked or ot ...

Installation

Installation

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transmission Mounting SystemINSTALLATION1. PITCHING STOPPER1. Install the pitching stopper.Tightening torque:T1: 50 N·m (5.1 kgf-m, 36.9 ft-lb)T2: ...

Other materials:

To set cruise control

Cruise control main button

1. Press the cruise control main button.

Cruise control indicator light (type A)

Cruise control indicator light (type B)

The cruise control indicator light on the

combination meter will illuminate.

2. Depress the accelerator pedal until the

vehicle rea ...

Clear memory mode Operation

EyeSight (DIAGNOSTICS) > Clear Memory ModeOPERATION1. On «Start» display, select «Diagnosis».2. On «Vehicle selection» display, input the target vehicle information and select «Confirmed».3. On «Main Menu» display, select «Each System».4. On «Select System» display, select «EyeSigh ...

Child restraint systems

Infants and small children should always

be placed in an infant or child restraint

system in the rear seat while riding in the

vehicle. You should use an infant or child

restraint system that meets Federal Motor

Vehicle Safety Standards or Canada

Motor Vehicle Safety Standards, is compatib ...