Subaru Crosstrek Service Manual: Installation

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Leak Check Valve Assembly

INSTALLATION

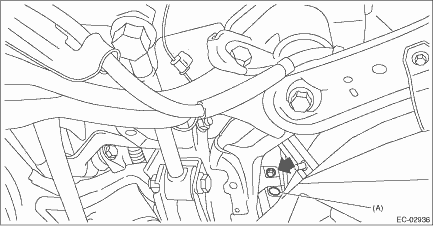

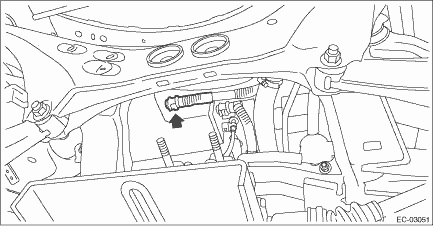

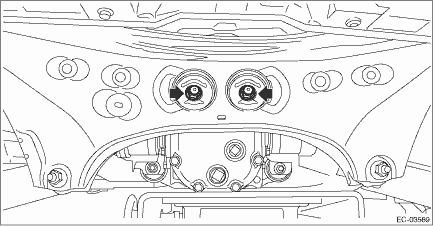

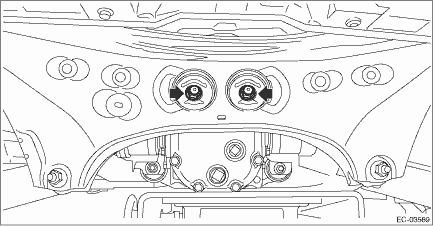

1. Install the leak check valve assembly to the vehicle with the bolt and clip (A).

Tightening torque:

7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

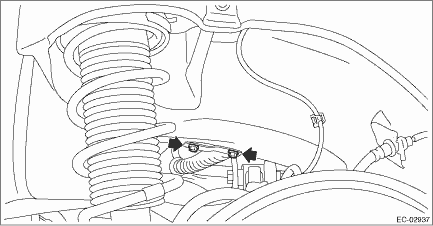

2. Connect the connector to the leak check valve assembly.

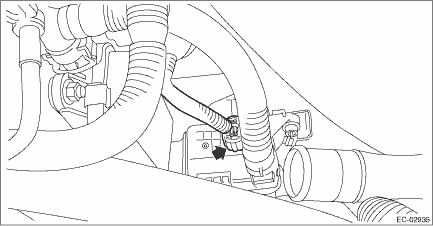

3. Connect the intake hose (C) to the connector.

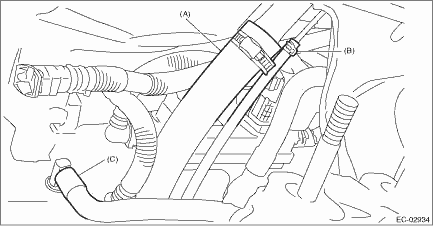

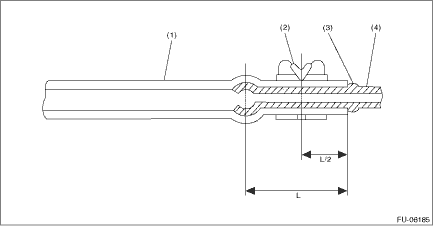

4. Securely insert the fuel filler hose (A) and evaporation hose (B) until the hose end contacts the spool, then attach the clamp and clip as shown in the figure.

Tightening torque:

2.5 N·m (0.3 kgf-m, 1.8 ft-lb)

(1) | Hose | (3) | Spool | (4) | Pipe |

(2) | Clamp and clip |

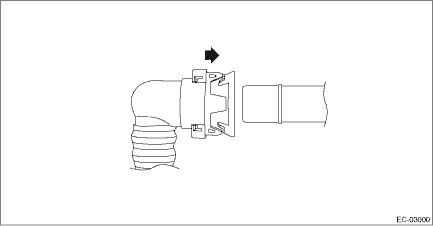

5. Connect the drain tube to the canister.

NOTE:

Connect the quick connector as shown in the figure.

6. Lift up the transmission jack gradually, and set the rear differential to the rear sub frame assembly.

NOTE:

When inserting the stud bolt into the bushing portion of the rear sub frame assembly, adjust the angle and location of transmission jack and jack stand.

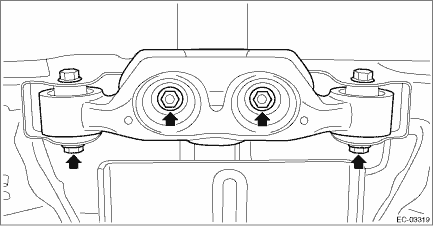

7. Temporarily tighten the self-locking nuts which hold the rear differential to the rear sub frame assembly.

NOTE:

Use a new self-locking nut.

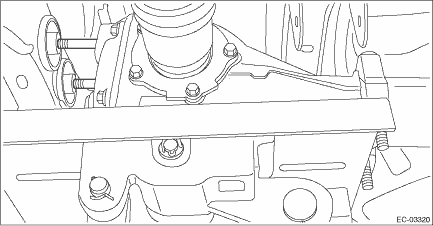

8. Set the rear differential member to the rear sub frame assembly and rear differential, and temporarily tighten the self-lock nuts which secure the rear differential member to the rear sub frame assembly and rear differential.

NOTE:

Use a new self-locking nut.

9. Remove the transmission jack from the rear differential.

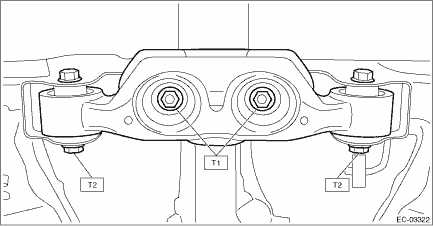

10. Tighten the self-locking nuts which secure the rear differential member to the rear sub frame assembly and rear differential.

Tightening torque:

T1: 50 N·m (5.1 kgf-m, 36.9 ft-lb)

T2: 110 N·m (11.2 kgf-m, 81.1 ft-lb)

11. Tighten the self-locking nuts which secure the rear differential to the rear sub frame assembly.

Tightening torque:

70 N·m (7.1 kgf-m, 51.6 ft-lb)

12. Install the propeller shaft. Propeller Shaft > INSTALLATION">

13. Install the rear exhaust pipe. Rear Exhaust Pipe > INSTALLATION">

14. Lower the vehicle.

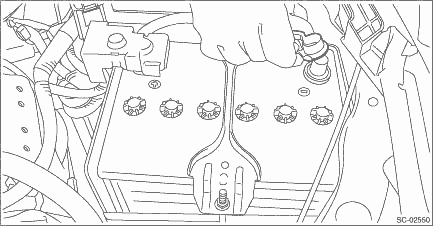

15. Connect the battery ground terminal.

Inspection

Inspection

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Leak Check Valve AssemblyINSPECTION1. CHECK SWITCHING VALVE1. Check the resistance between switching valve terminals.Terminal No.Standard1 a ...

Pcv hose

Pcv hose

...

Other materials:

Diagnostics with phenomenon Inspection

Blind Spot Detection/Rear Cross Traffic Alert (DIAGNOSTICS) > Diagnostics with PhenomenonINSPECTIONSymptomsMaintenance partsBSD/RCTA does not operate.FuseLAN system Basic Diagnostic Procedure">Body control system Basic Diagnostic Procedure">Radar sensor LHRadar sensor RHBSD/RCTA ...

Operation

KEYLESS ACCESS WITH PUSH BUTTON START SYSTEM (DIAGNOSTICS) > Read Current DataOPERATION1. On «Start» display, select «Diagnosis».2. On «Vehicle selection» display, input the target vehicle information and select «Confirmed».3. On «Main Menu» display, select «Each System».4. On «Selec ...

Tripped sensor identification

The security indicator light flashes when

the alarm system has been triggered.

Also, the number of flashes indicates the

location of unauthorized intrusion or the

severity of impact on the vehicle.

When the ignition switch is turned to the

"ON" position, the indicator light will light

for ...