Subaru Crosstrek Service Manual: Installation

DRIVE SHAFT SYSTEM > Rear Axle

INSTALLATION

1. Temporarily tighten the rear axle housing to the upper arm assembly.

2. Install the rear drive shaft assembly.

CAUTION:

• Do not hammer the drive shaft assembly when installing.

• Use new axle nuts.

(1) Insert the drive shaft assembly into the hub spline, and pull it into the specified position.

(2) Tighten the axle nut temporarily.

3. Tighten the rear strut assembly, rear stabilizer link and other links to the specified torque.

Tightening torque:

Rear suspension: General Description > COMPONENT">

Rear strut: General Description > COMPONENT">

4. Install the rear disc rotor.

5. Install the caliper body assembly.

Tightening torque:

Refer to “COMPONENT” of “General Description” for the tightening torque. General Description > COMPONENT">

6. Install the brake hose bracket and rear ABS wheel speed sensor.

Tightening torque:

Brake hose bracket: 33 N·m (3.4 kgf-m, 24.3 ft-lb)

Rear ABS wheel speed sensor: 7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

7. Install the sensor assembly - headlight beam leveler. (Model with auto headlight beam leveler)

Tightening torque:

7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

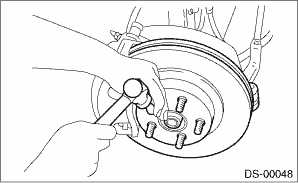

8. While pressing the brake pedal, tighten the new axle nuts to the specified torque.

CAUTION:

Do not load the rear axle before tightening the axle nut. Doing so may damage the hub unit bearing.

Tightening torque:

190 N·m (19.4 kgf-m, 140.1 ft-lb)

9. After tightening the axle nut, lock it securely.

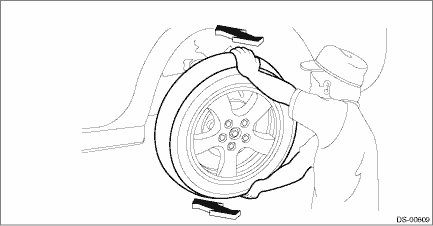

10. Install the rear wheels, and perform the following inspections.

Tightening torque:

Except for C4 model: 120 N·m (12.2 kgf-m, 88.5 ft-lb)

C4 model: 100 N·m (10.2 kgf-m, 73.8 ft-lb)

(1) Check the wheels for smooth rotation.

(2) Check that there is no looseness by moving the upper and lower portions of rear tire in an axial direction with the brake pedal released.

• Looseness exists > Check the rear hub unit bearing. Rear Hub Unit Bearing > INSPECTION">

11. Inspect the wheel alignment and adjust if necessary.

• Inspection: Wheel Alignment > INSPECTION">

• Adjustment: Wheel Alignment > ADJUSTMENT">

12. Perform reinitialization of the auto headlight beam leveler system. (Model with auto headlight beam leveler) Auto Headlight Beam Leveler System > PROCEDURE">

Disassembly

Disassembly

DRIVE SHAFT SYSTEM > Rear AxleDISASSEMBLY1. BUSHING - REAR AXLE HOUSINGDo not remove the bushing - rear axle housing from the rear axle housing, because it cannot be replaced. If removed, replace t ...

Rear drive shaft

Rear drive shaft

...

Other materials:

Preparation tool

VEHICLE DYNAMICS CONTROL (VDC) > General DescriptionPREPARATION TOOL1. SPECIAL TOOLILLUSTRATIONTOOL NUMBERDESCRIPTIONREMARKS — SUBARU SELECT MONITOR 4Used for setting of each function and troubleshooting for electrical system.NOTE:For detailed operation procedures of Subaru Select Monitor 4, re ...

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Control Valve BodyREMOVALCAUTION:• Directly after the vehicle has been running or the engine has been idling for a long time, the CVTF is hot. Be careful not to burn yourself.• Be careful not to spill CVTF on the exhaust pipe to prevent it f ...

Diagnostics with phenomenon Inspection

Blind Spot Detection/Rear Cross Traffic Alert (DIAGNOSTICS) > Diagnostics with PhenomenonINSPECTIONSymptomsMaintenance partsBSD/RCTA does not operate.FuseLAN system Basic Diagnostic Procedure">Body control system Basic Diagnostic Procedure">Radar sensor LHRadar sensor RHBSD/RCTA ...