Subaru Crosstrek Service Manual: Assembly

MECHANICAL(H4DO) > Cylinder Block

ASSEMBLY

1. CYLINDER BLOCK

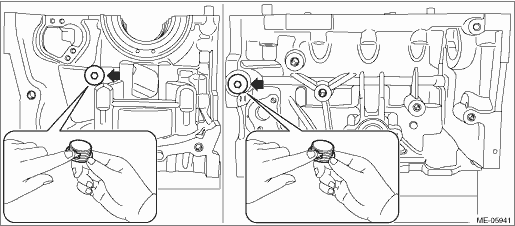

1. Apply liquid gasket to the threaded portion of the main gallery plug, and install the main gallery plug to the cylinder block LH.

NOTE:

Before applying liquid gasket, degrease the thread holes of the cylinder block LH and main gallery plug.

Liquid gasket:

THREE BOND 1105 (Part No. 004403010) or equivalent

Tightening torque:

37 N·m (3.8 kgf-m, 27.3 ft-lb)

2. Install the cylinder block plate onto cylinder block LH.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

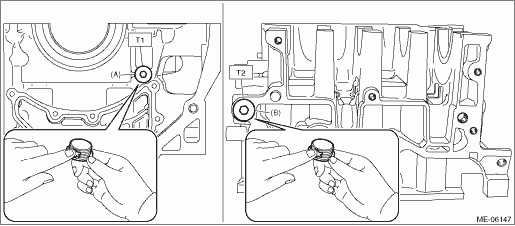

3. Apply liquid gasket to the threaded portions of cylinder block plug and main gallery plug, and install the cylinder block plug (A) and main gallery plug (B) to cylinder block RH.

NOTE:

Before applying liquid gasket, degrease the thread holes of the cylinder block RH, and the threaded portions of cylinder block plug and main gallery plug.

Liquid gasket:

THREE BOND 1105 (Part No. 004403010) or equivalent

Tightening torque:

T1: 16 N·m (1.6 kgf-m, 11.8 ft-lb)

T2: 37 N·m (3.8 kgf-m, 27.3 ft-lb)

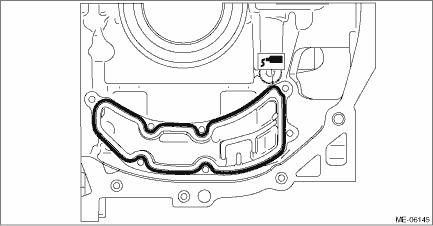

4. Install the oil separator cover to the cylinder block RH.

(1) Apply liquid gasket to the mating surfaces of oil separator cover.

NOTE:

• Use new oil separator cover.

• Before applying liquid gasket, degrease the old liquid gasket seal surface of cylinder block RH.

• Install within 5 min. after applying liquid gasket.

Liquid gasket:

Mating surface

THREE BOND 1217G (Part No. K0877Y0100), THREE BOND 1217H or equivalent

Liquid gasket applying diameter:

4±1 mm (0.1772±0.0197 in)

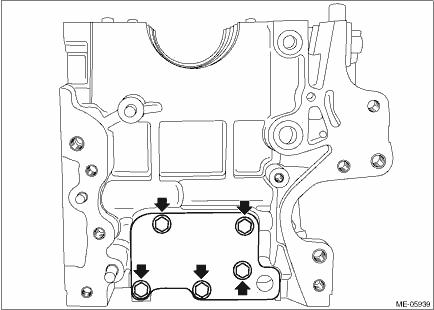

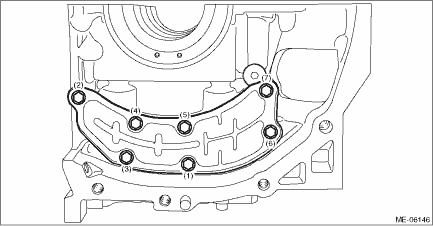

(2) Install the oil separator cover to the cylinder block RH, and tighten the oil separator cover bolts in numerical order as shown in the figure.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

2. PISTON AND CONNECTING ROD

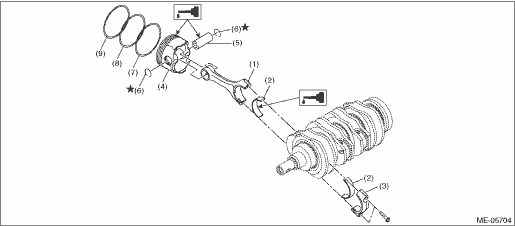

(1) | Connecting rod | (4) | Piston | (7) | Oil ring |

(2) | Connecting rod bearing | (5) | Piston pin | (8) | Second ring |

(3) | Connecting rod cap | (6) | Circlip | (9) | Top ring |

1. Install the connecting rod bearing to the connecting rod and connecting rod cap.

2. Install the circlip on one end of the piston using a flat tip screwdriver.

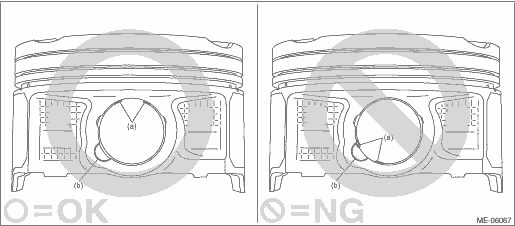

NOTE:

• Be careful not damage the piston, by wrapping the tip of flat tip screwdriver with tape.

• Make sure the circlip is firmly inserted into the circlip groove.

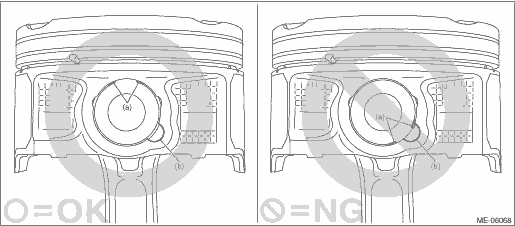

• After installing the circlip, rotate the circlip so that its end part (a) and the cutout portion of circlip groove (b) do not match.

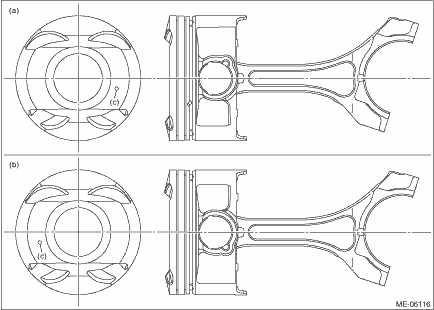

3. Set the piston to the connecting rod.

NOTE:

Align the front mark of piston and the connecting rod direction correctly as shown in the figure.

(a) | RH side (#1 and #3) | (b) | LH side (#2 and #4) | (c) | Front mark |

4. Apply engine oil to the piston pin, and attach the piston pin.

5. Install the circlip on the piston using a flat tip screwdriver.

NOTE:

• Be careful not damage the piston and piston pin, by wrapping the tip of flat tip screwdriver with tape.

• Make sure the circlip is firmly inserted into the circlip groove.

• After installing the circlip, rotate the circlip so that its end part (a) and the cutout portion of circlip groove (b) do not match.

6. Install the piston rings onto the piston.

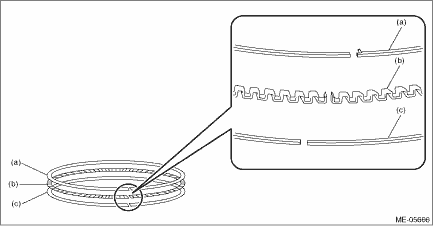

(1) Install the oil rings in the order of expander, lower rail and upper rail by hand.

NOTE:

Oil ring consists of the upper rail, expander and lower rail.

(a) | Upper rail | (b) | Expander | (c) | Lower rail |

(2) Install the compression rings in the order of second ring and top ring, using piston ring expander.

NOTE:

Install so that the compression ring mark faces the top side of the piston.

Cylinder block

Cylinder block

...

Installation

Installation

MECHANICAL(H4DO) > Cylinder BlockINSTALLATION1. Apply engine oil to the crankshaft bearing, and install the crankshaft bearing to the cylinder block.CAUTION:• Place a wood board wrapped with ...

Other materials:

Disposal

REAR SUSPENSION > Rear Shock AbsorberDISPOSALCAUTION:• Before discarding the strut COMPL and the shock absorber COMPL, be sure to wear goggles to protect eyes from gas, oil and cutting powder.• Do not disassemble the strut COMPL and the shock absorber COMPL or throw them into flames.& ...

Inspection

LIGHTING SYSTEM > Day Time Running Light SystemINSPECTION1. DAYTIME RUNNING LIGHT SYSTEM CHECKSTEPCHECKYESNO1.CHECK FUSE.1) Turn the ignition switch to OFF.2) Check the headlight HI fuse.Is the fuse OK? Day Time Running Light System > INSPECTION">Go to Step 2.Replace the fuse.2.CHECK R ...

Loading a disc

CAUTION

Never try to disassemble the audio

kit or lubricate any part of the CD

player. Do not insert anything other

than a disc into the slot.

Insert a disc into the disc slot. After

insertion, the disc is automatically loaded.

NOTE

When inserting a disc, gently insert it

with the label ...